Category: Uncategorized

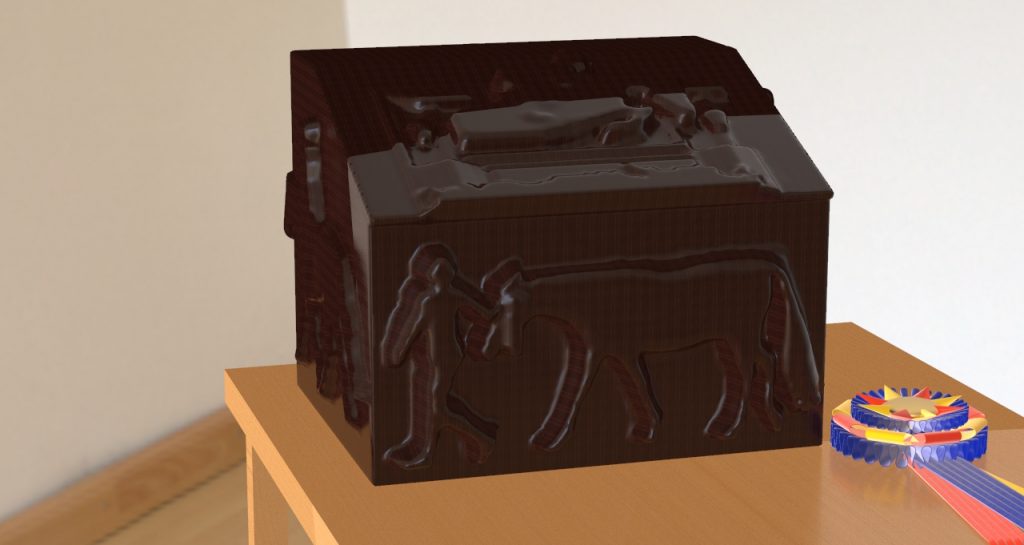

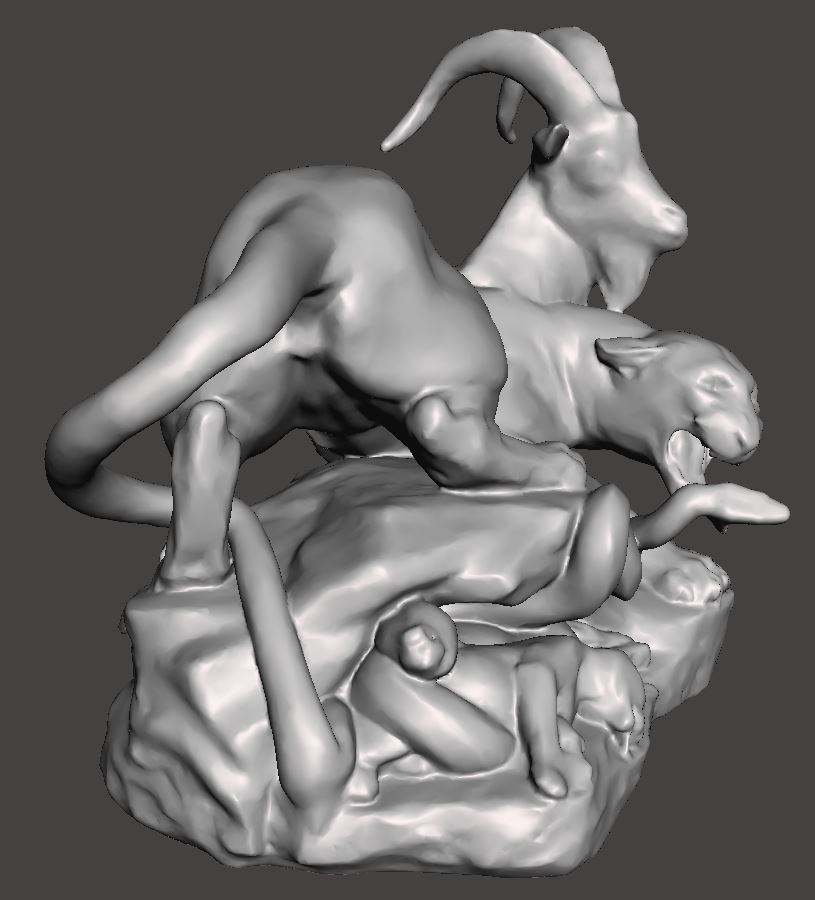

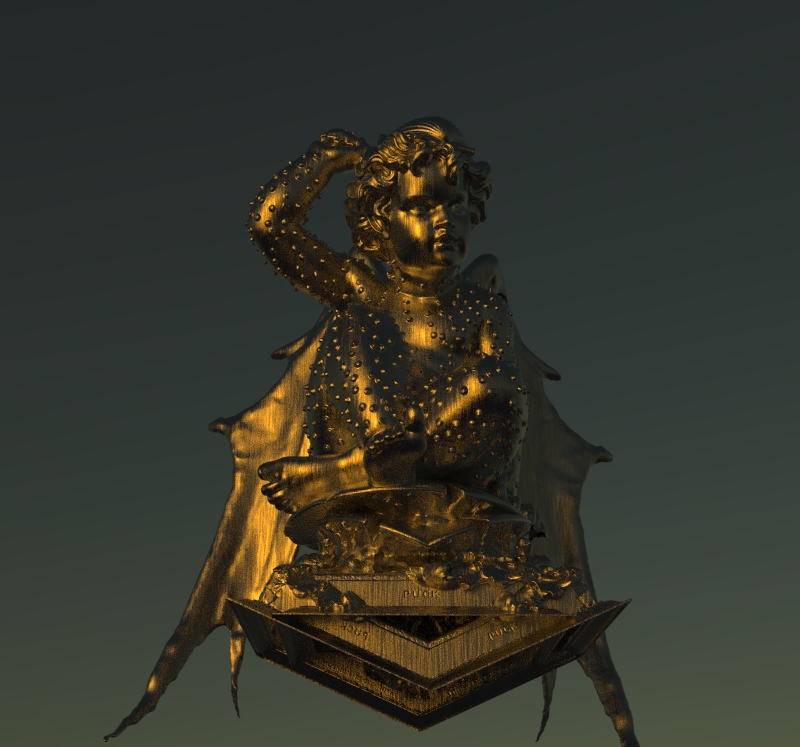

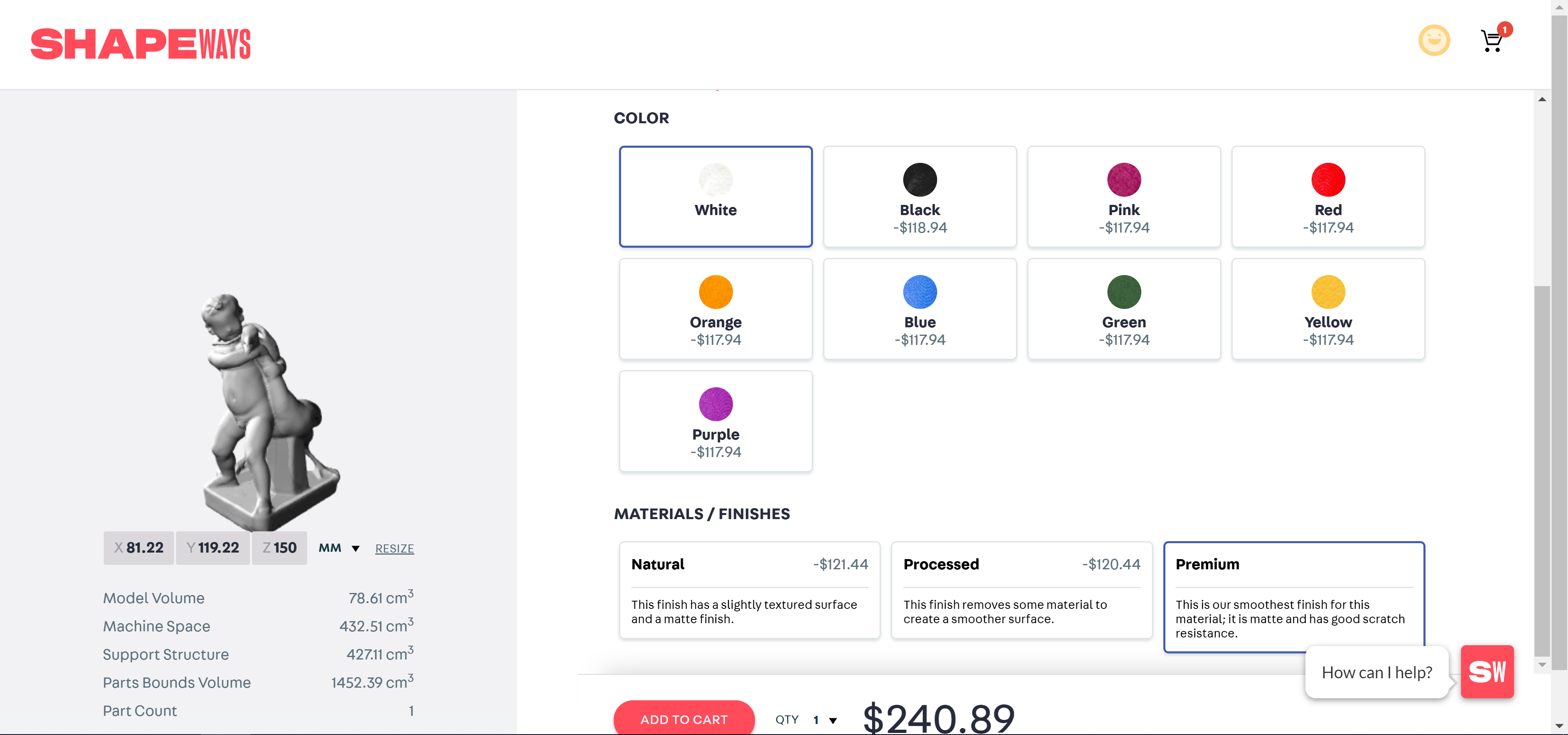

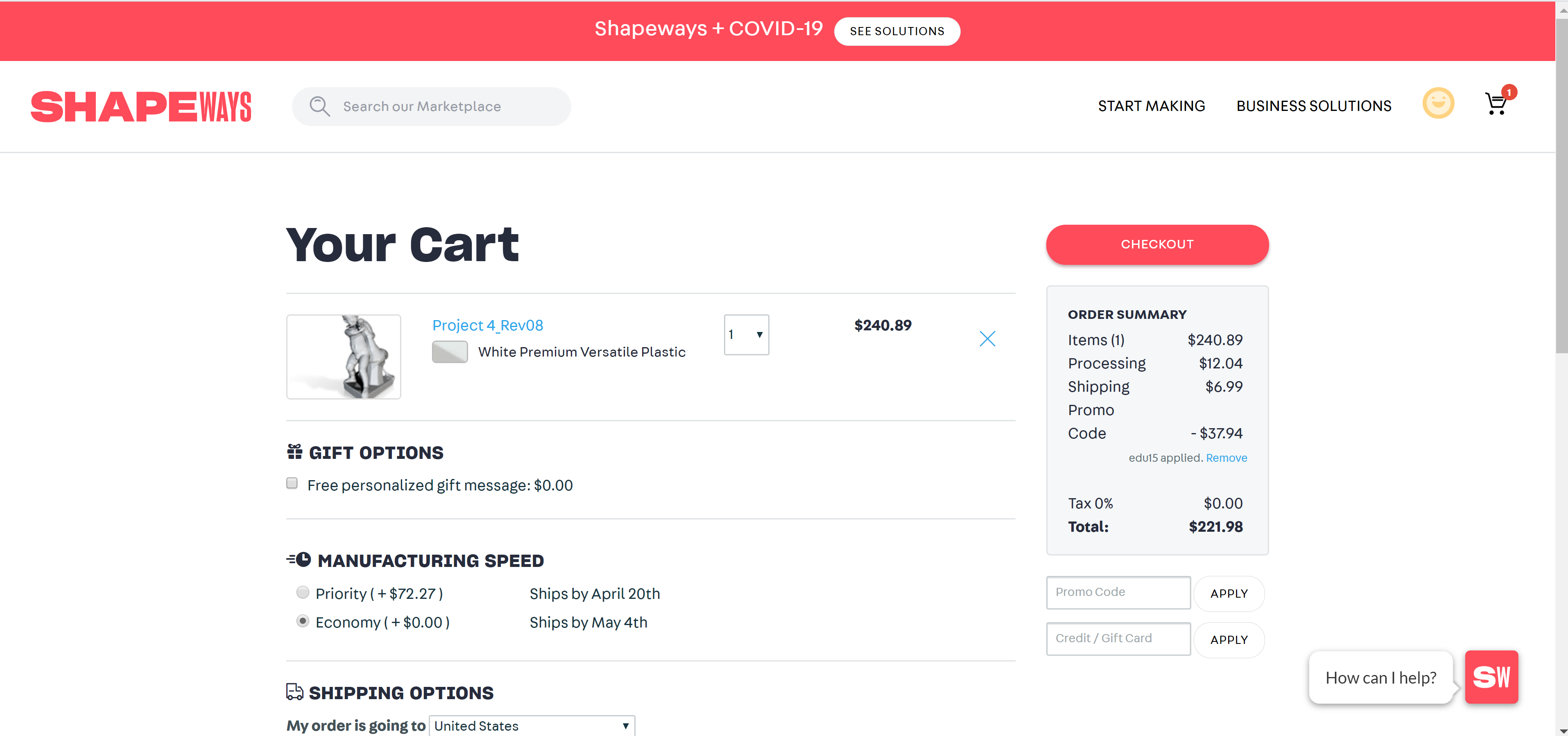

James Bennett, Project 4 3D Print via Shapeways

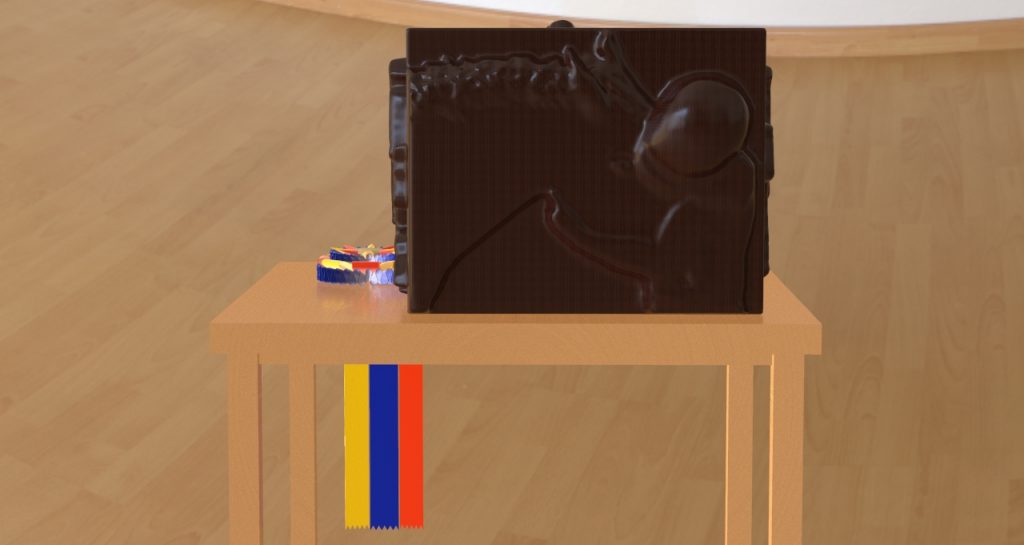

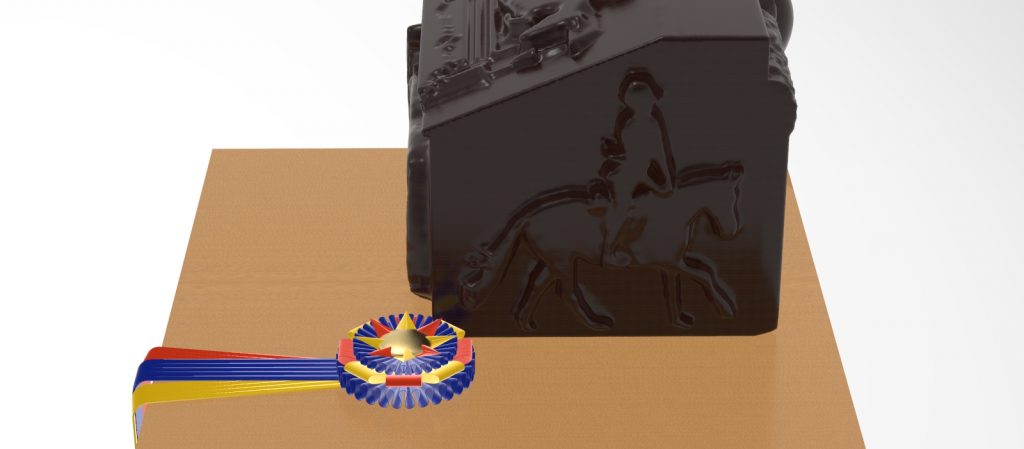

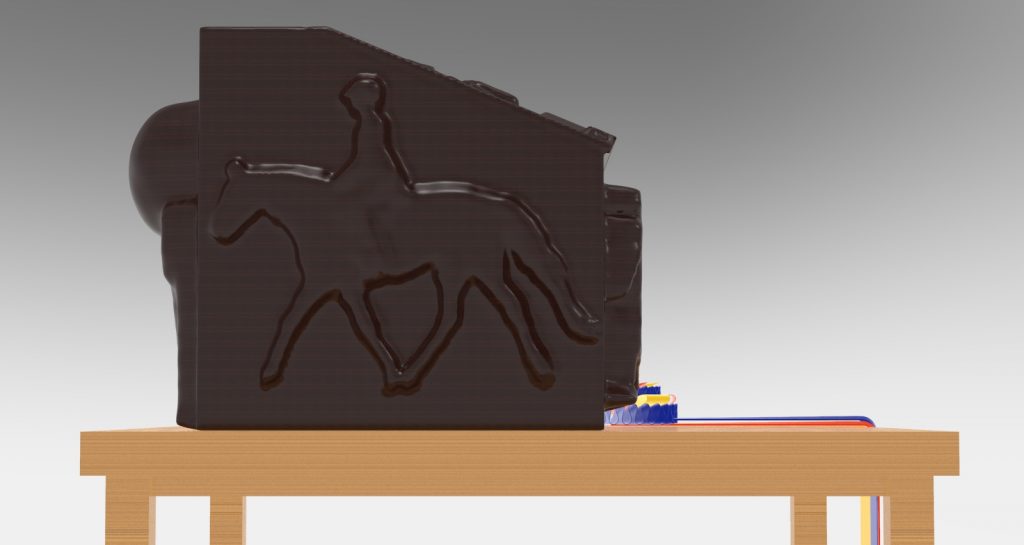

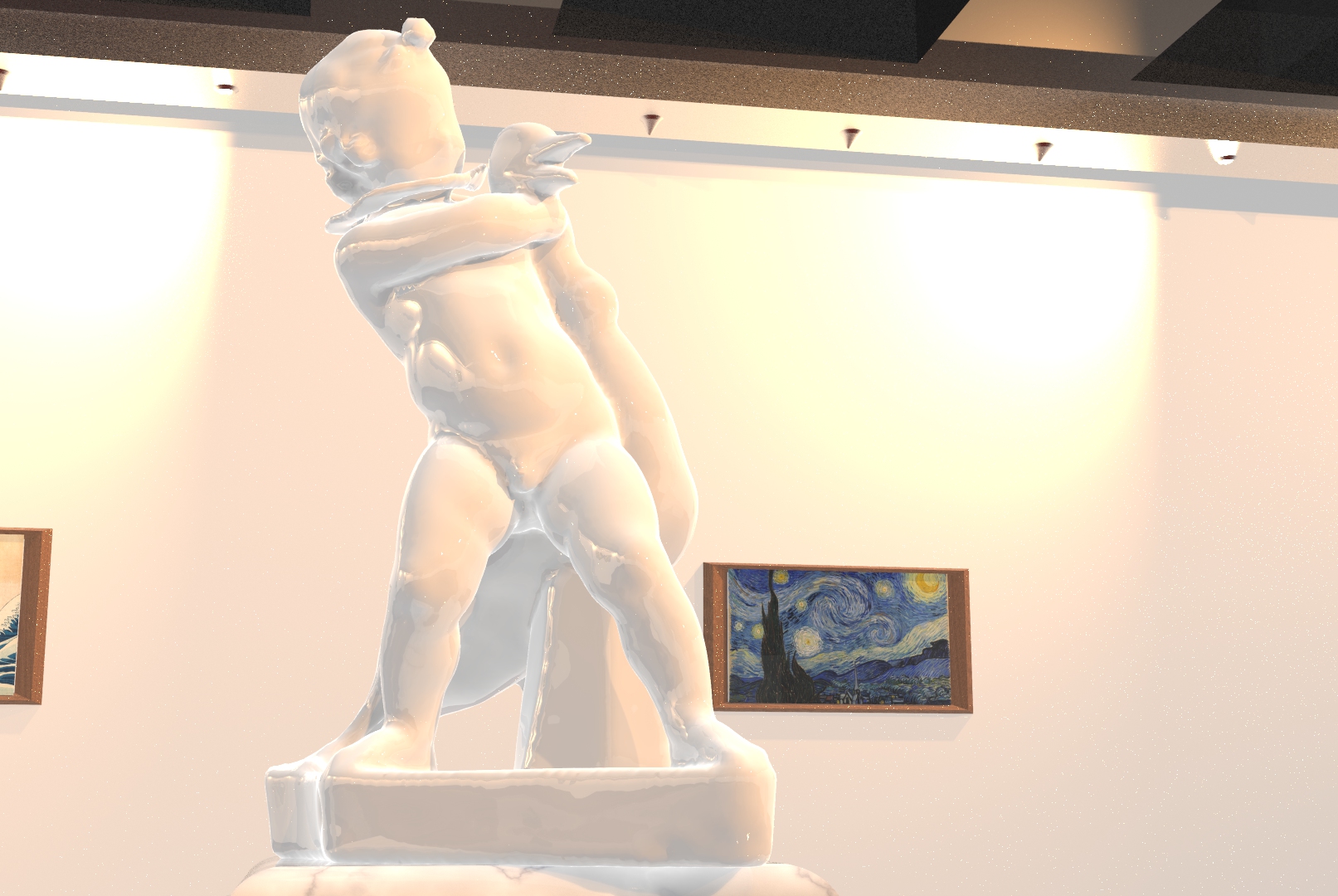

James Bennett, Project 4 in Museum

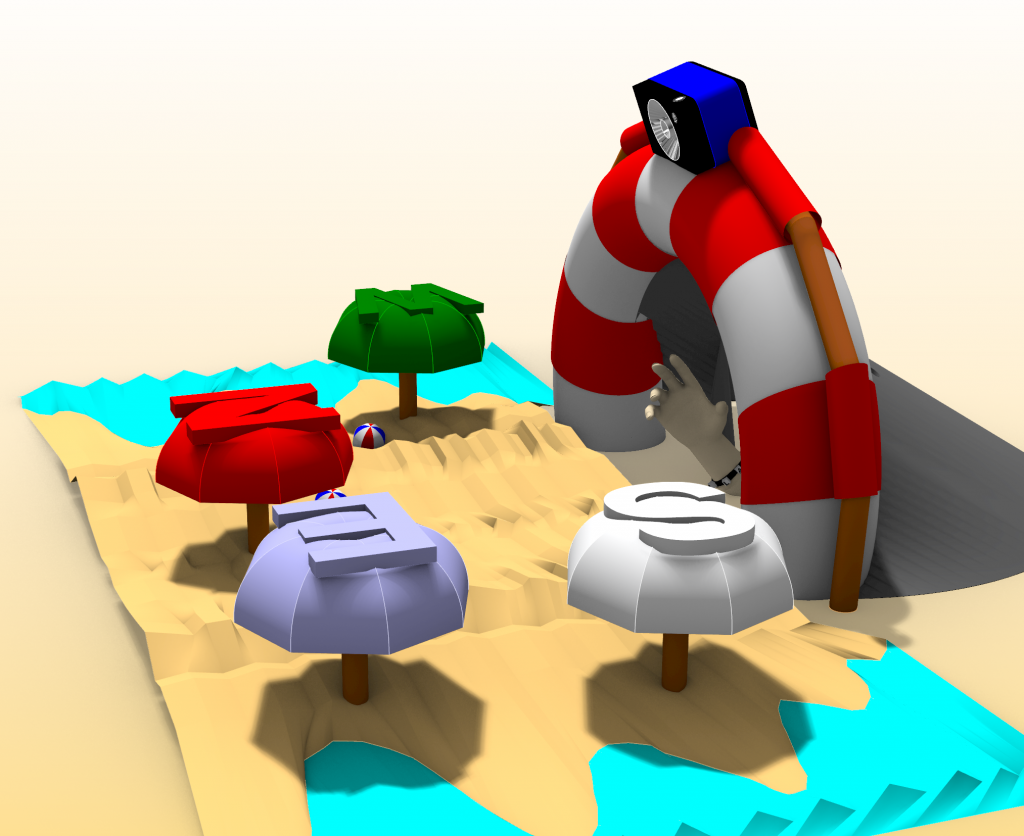

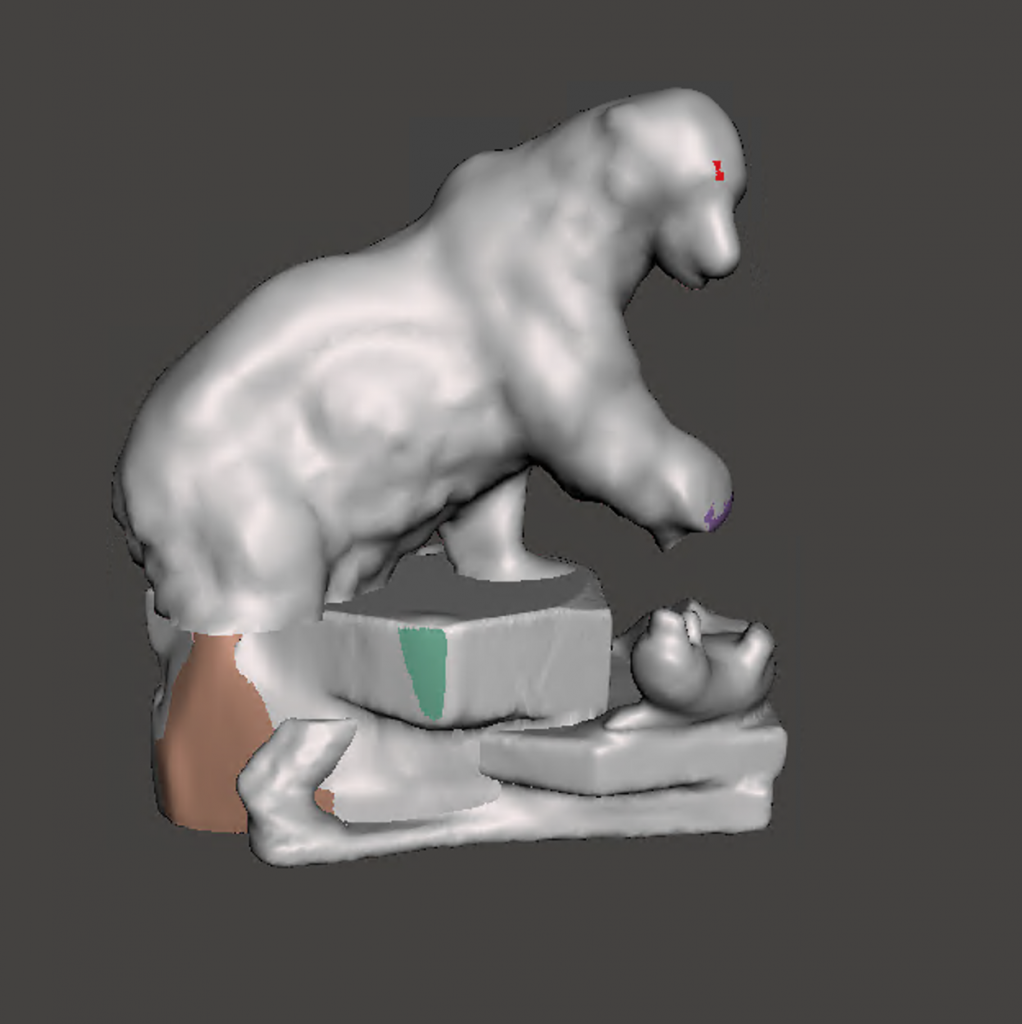

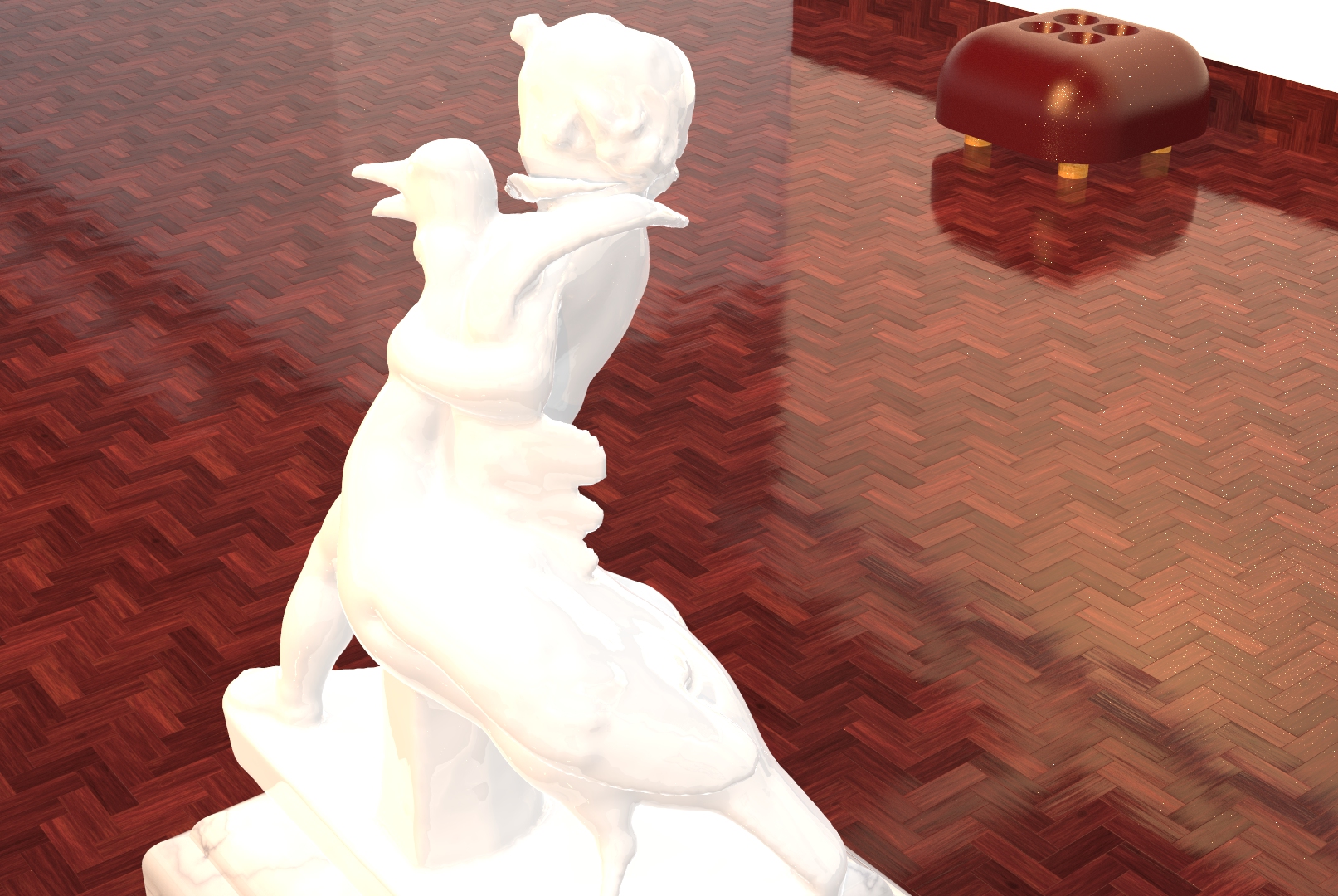

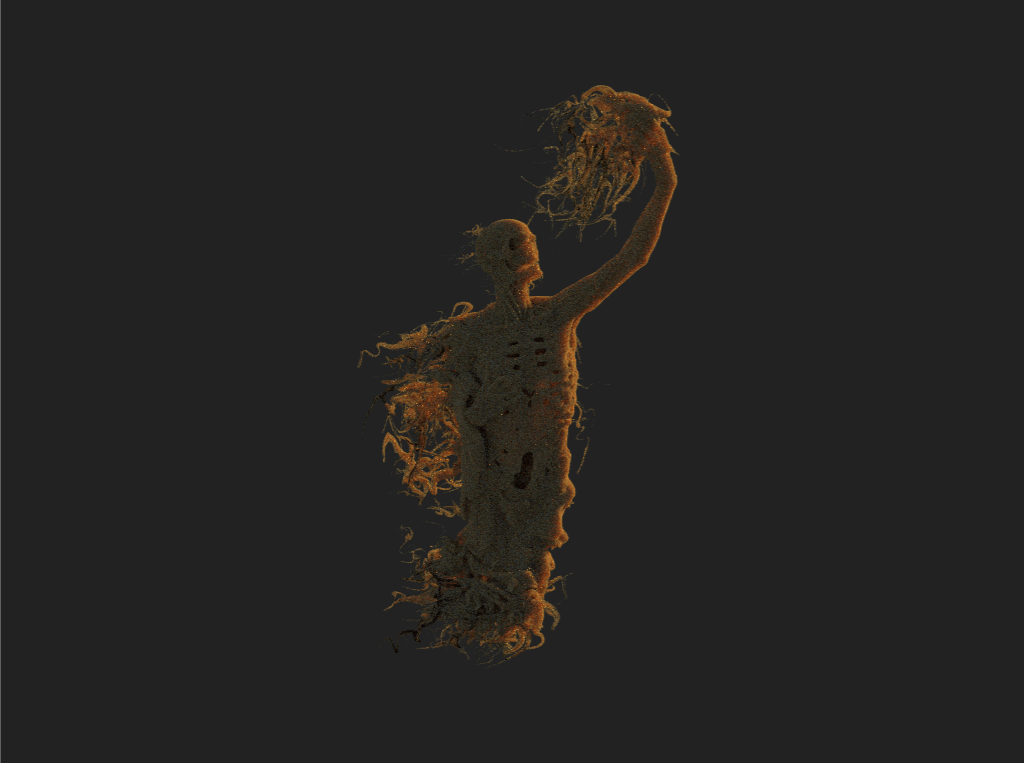

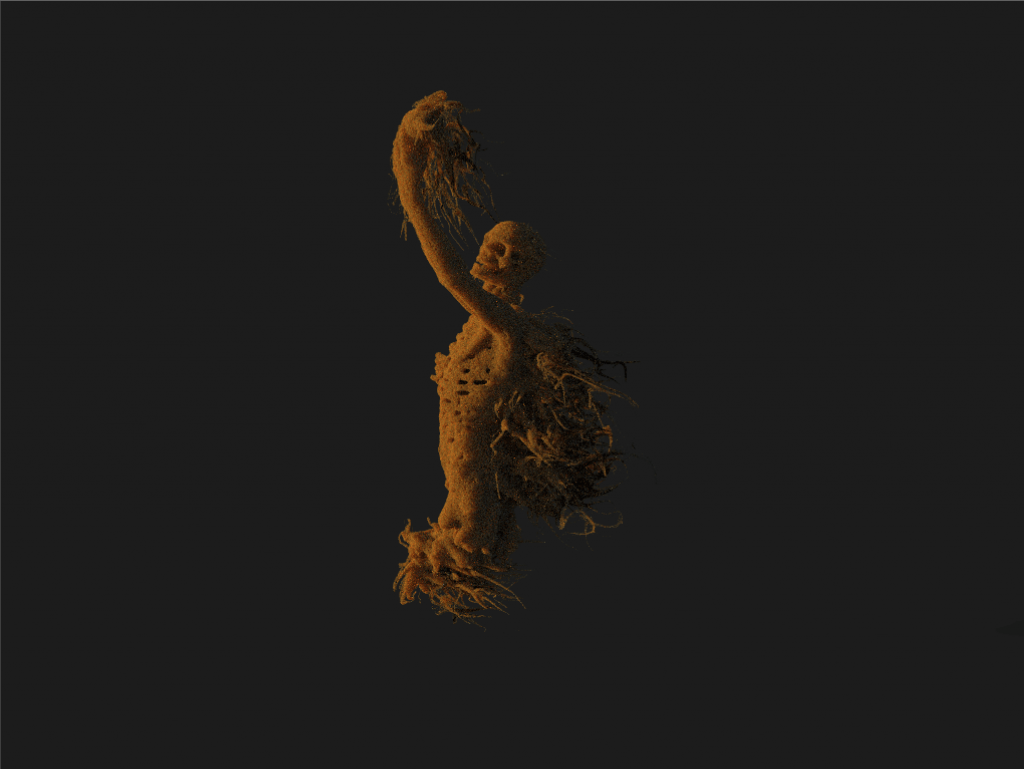

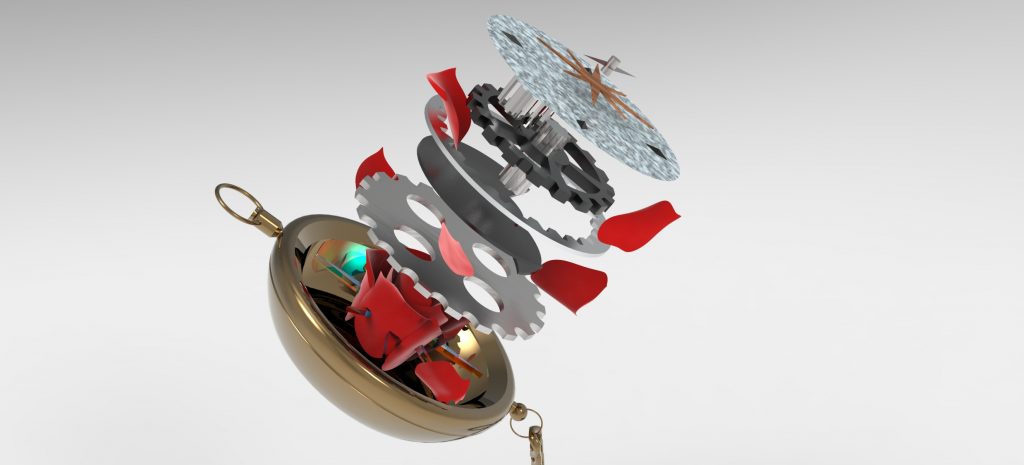

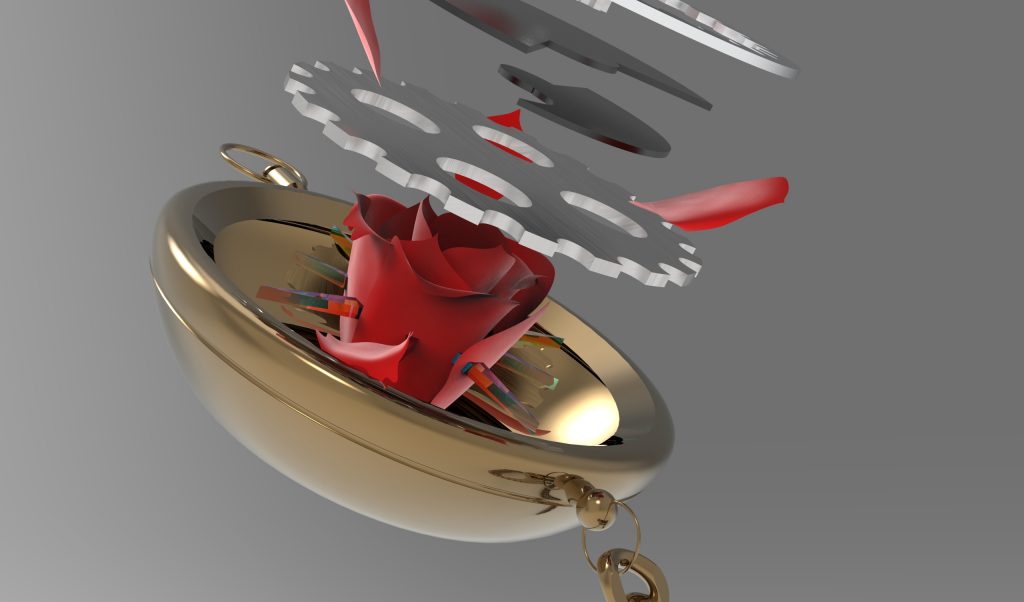

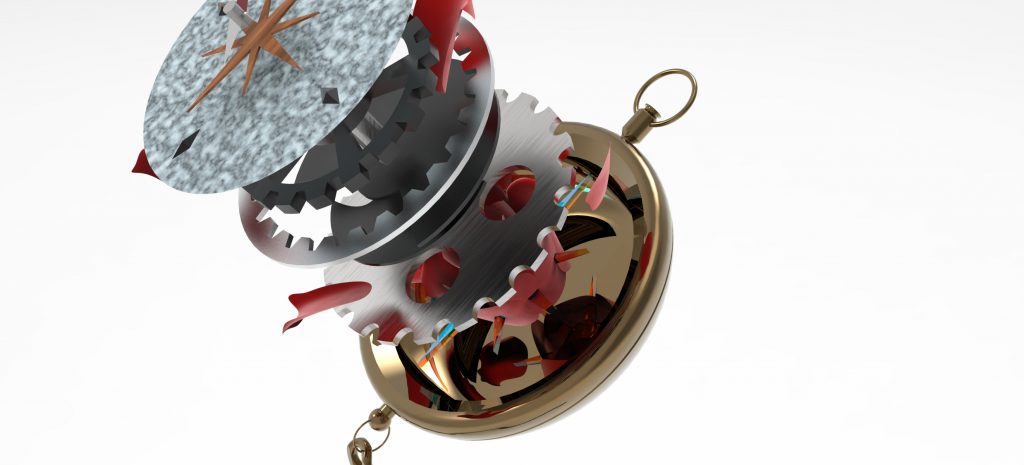

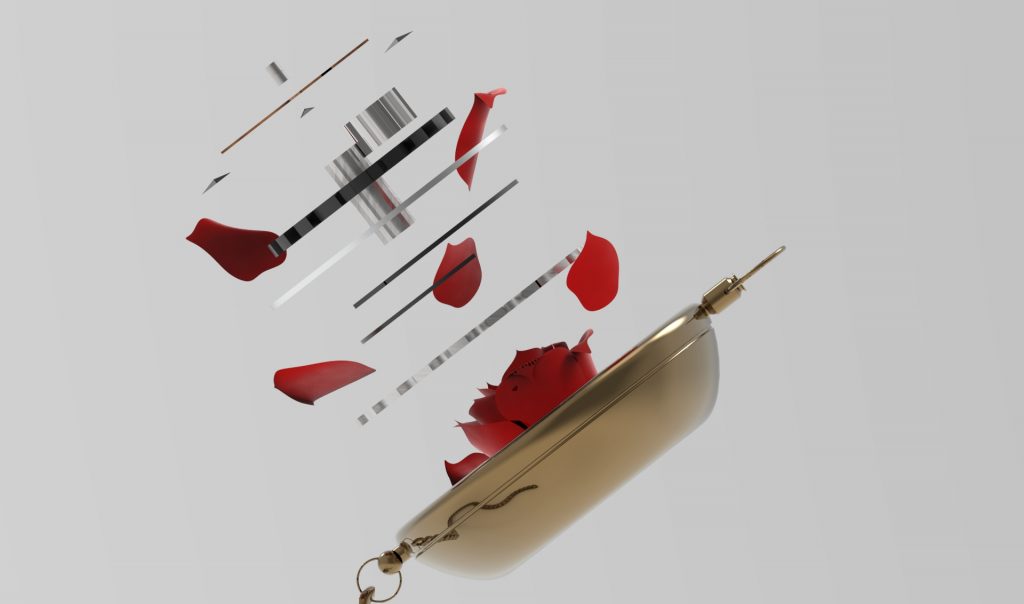

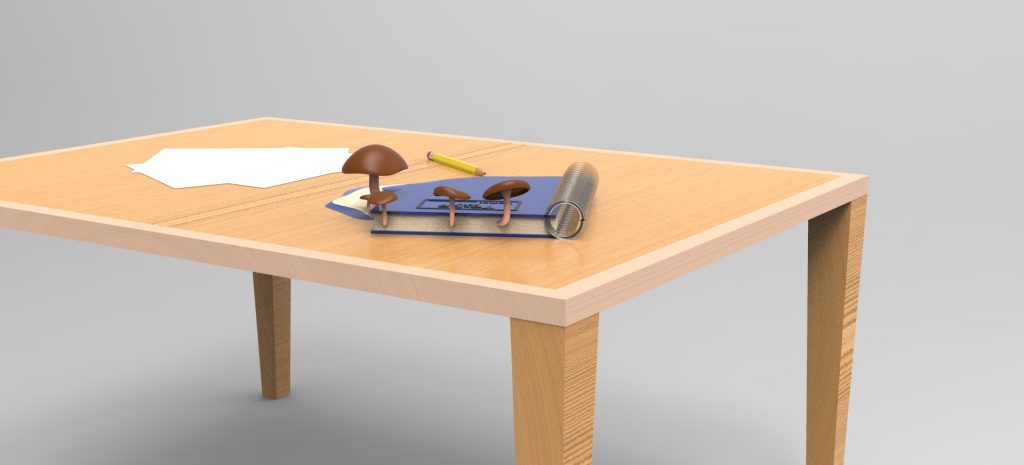

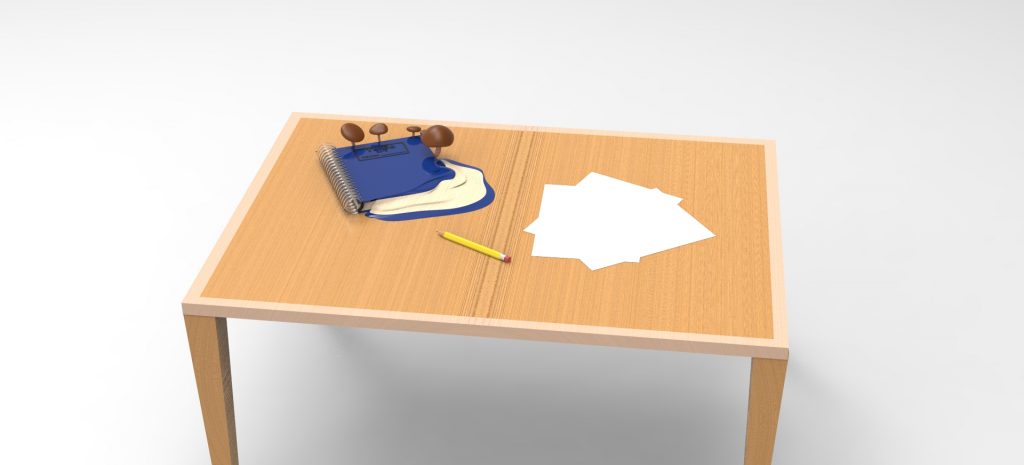

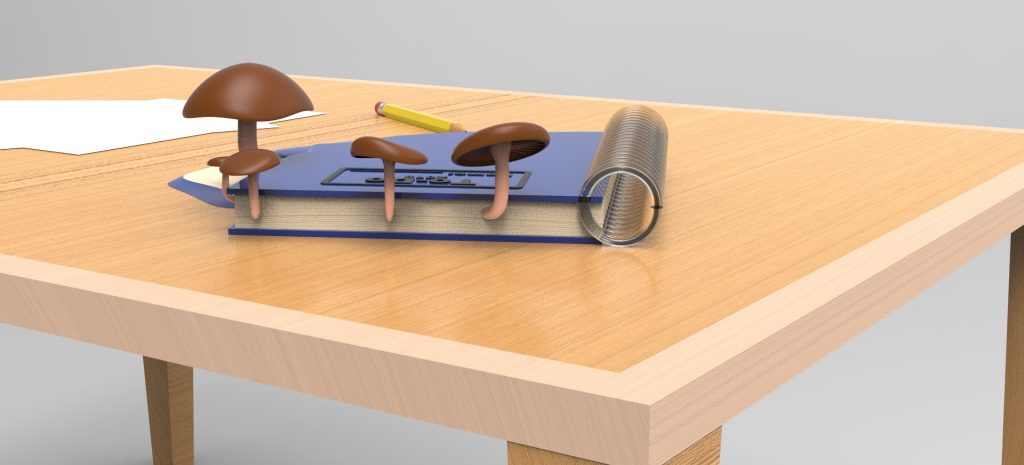

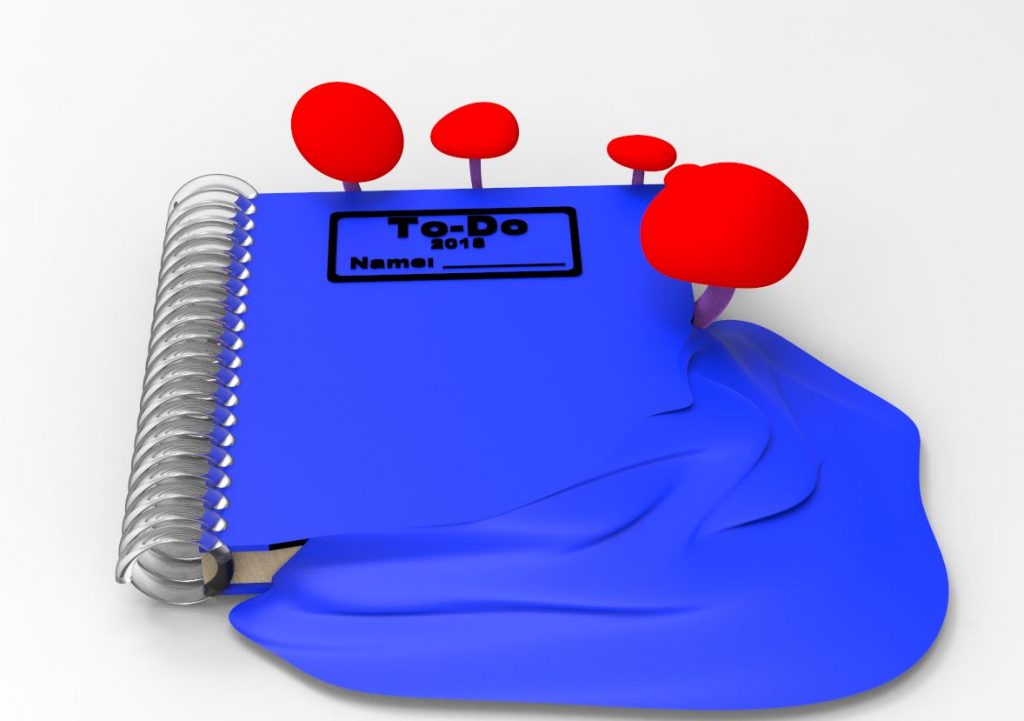

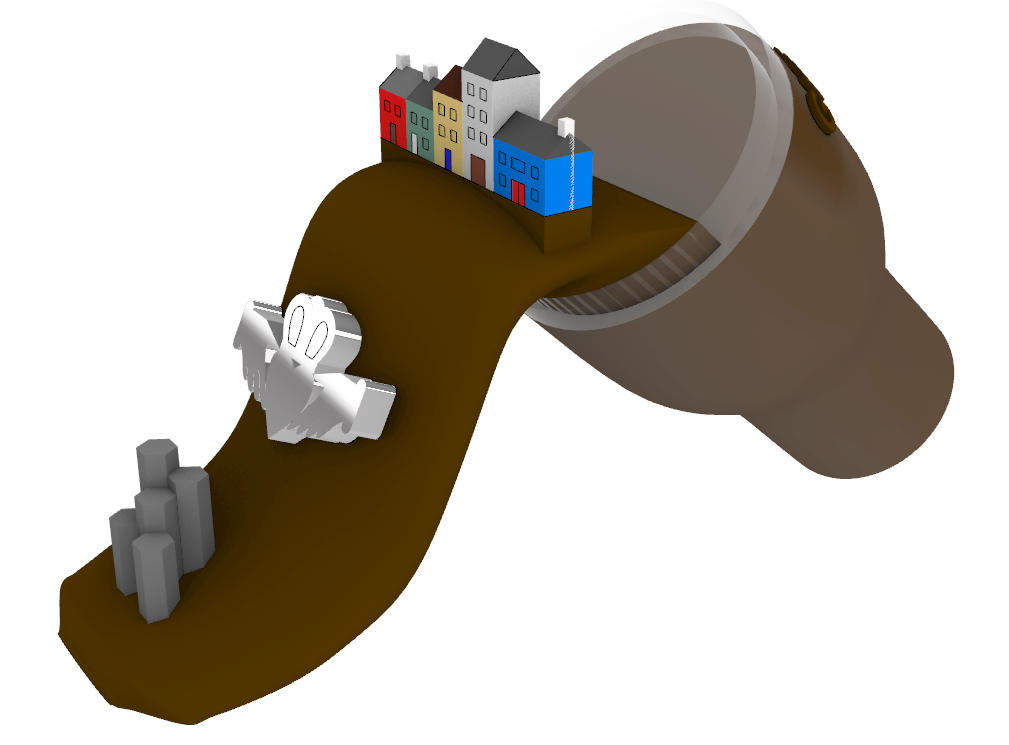

Aaron Li, project 4 render

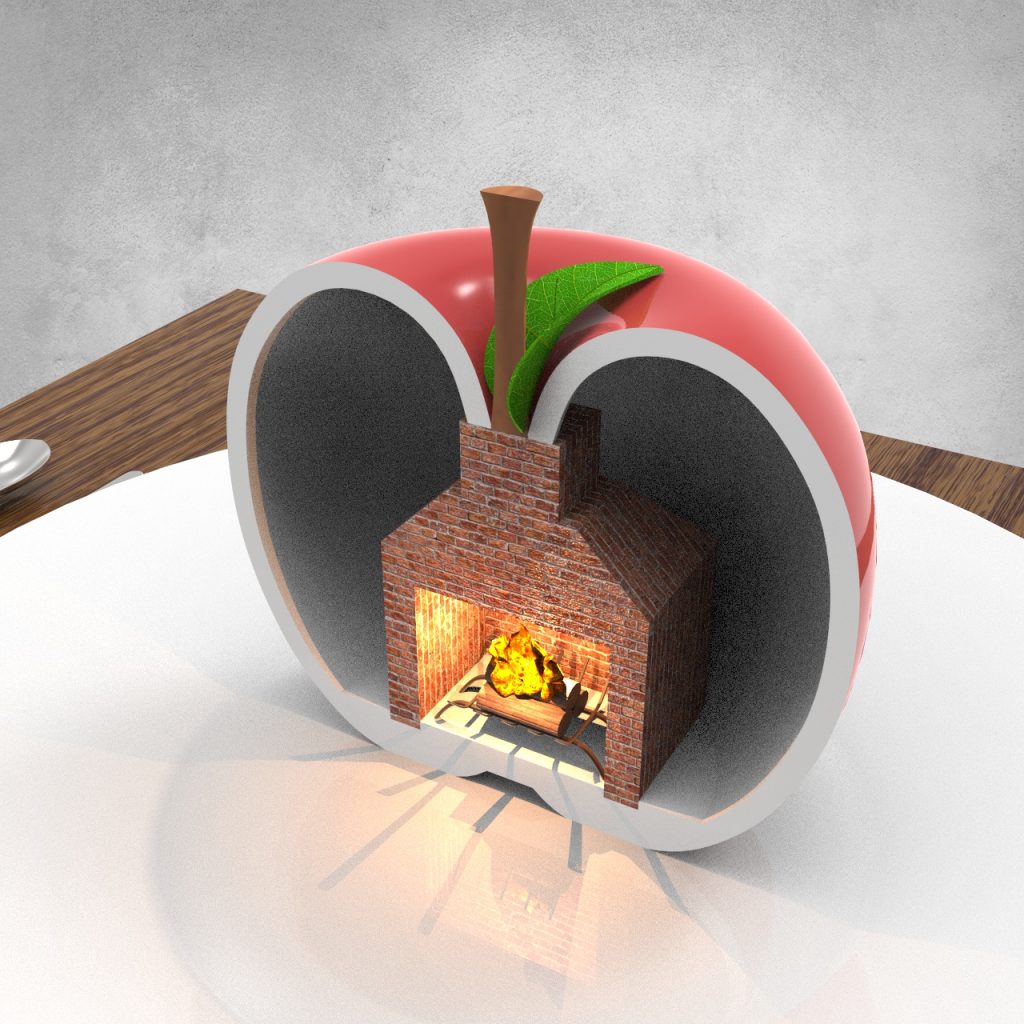

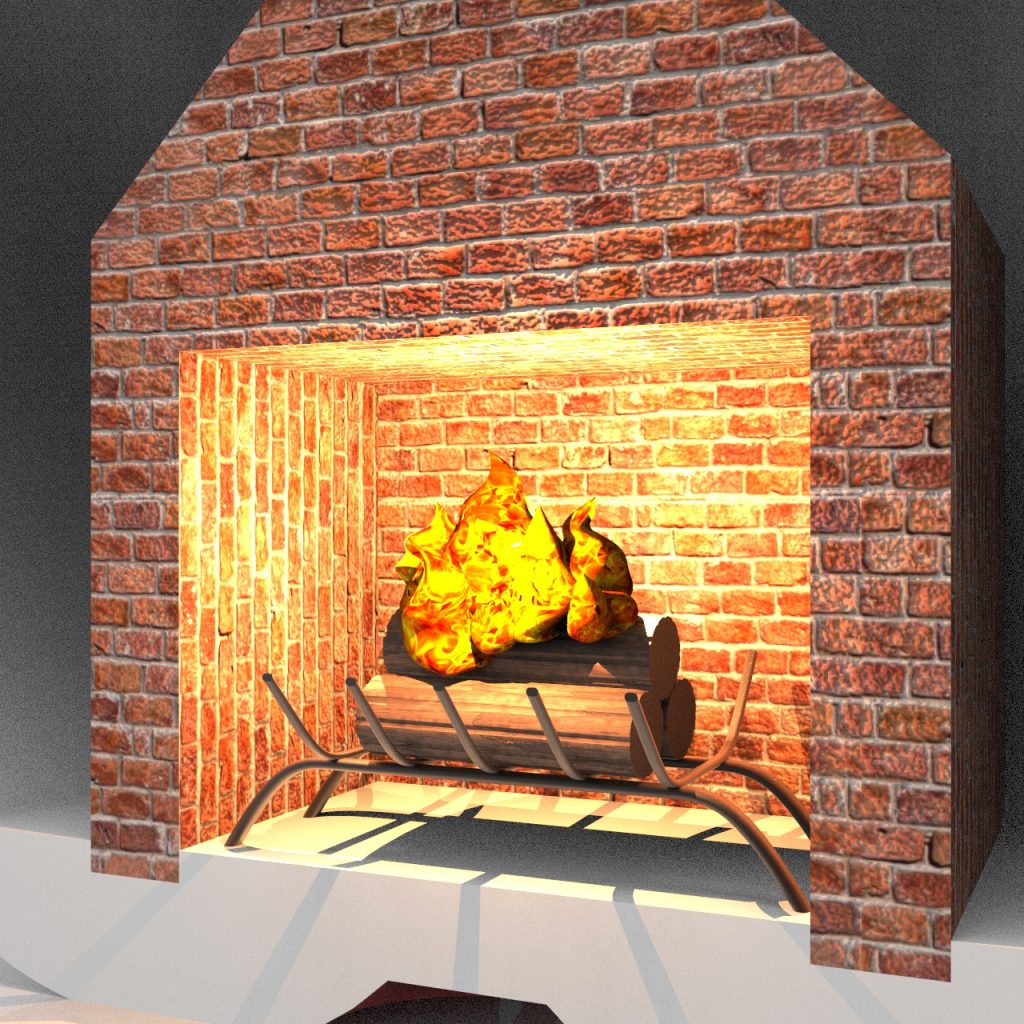

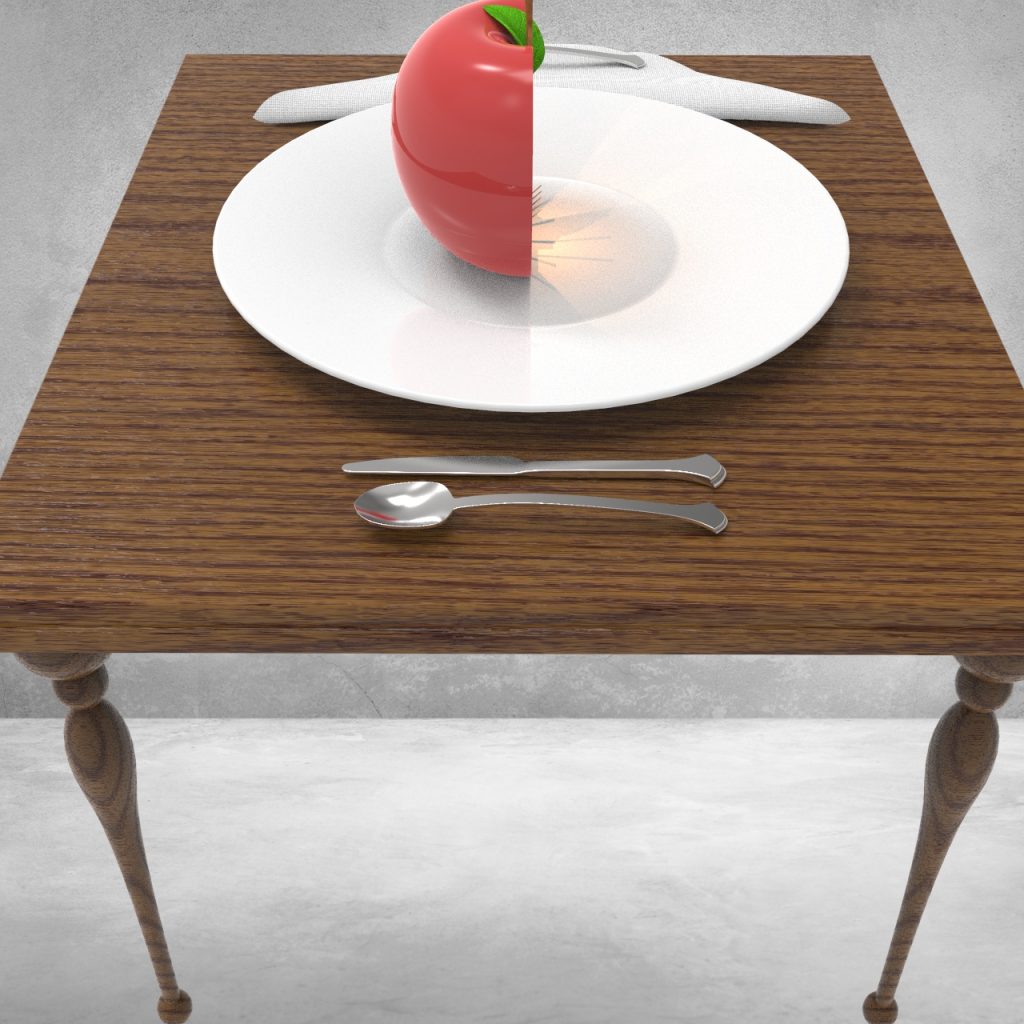

Weiwei Gu-Project 4 Rendered

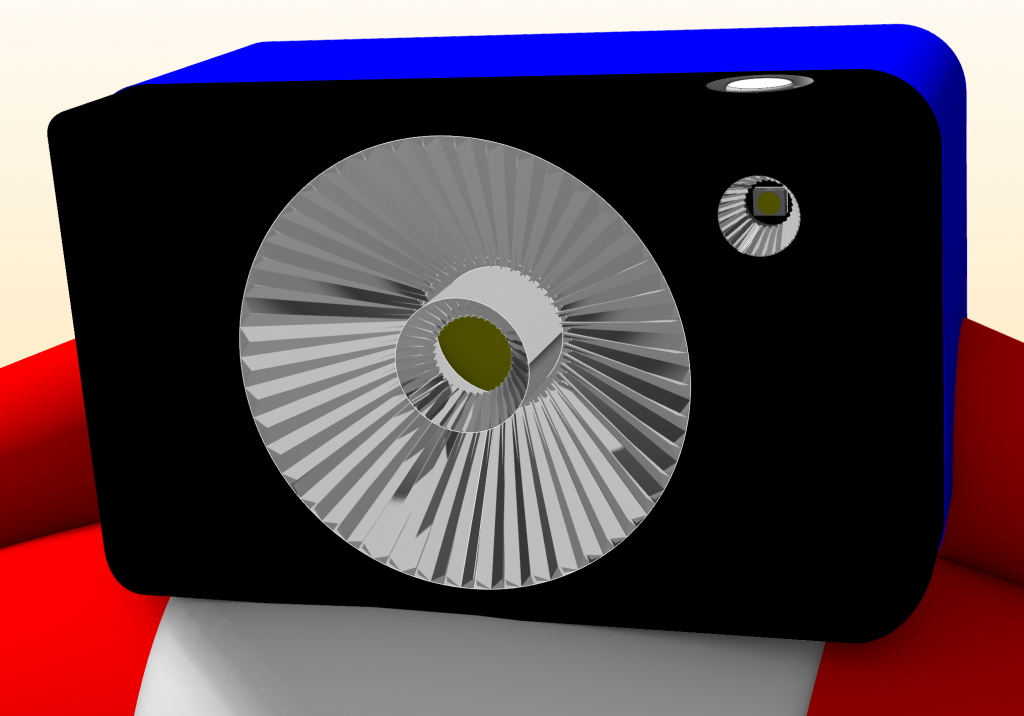

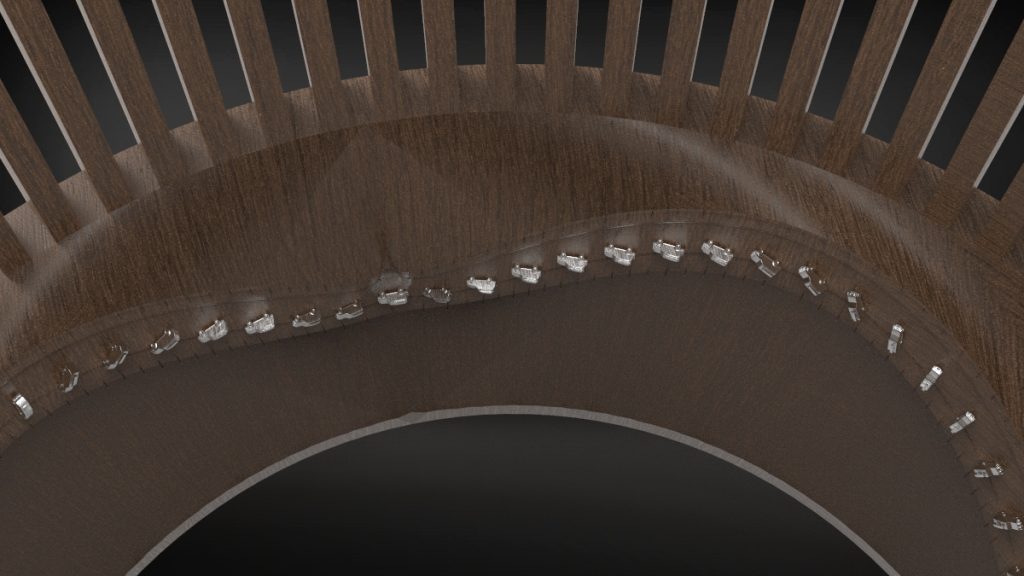

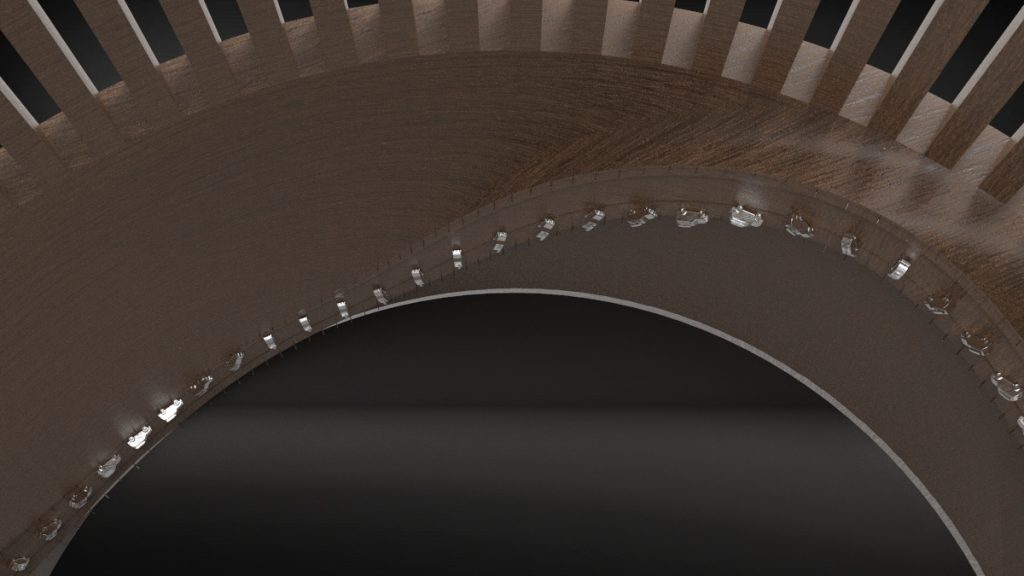

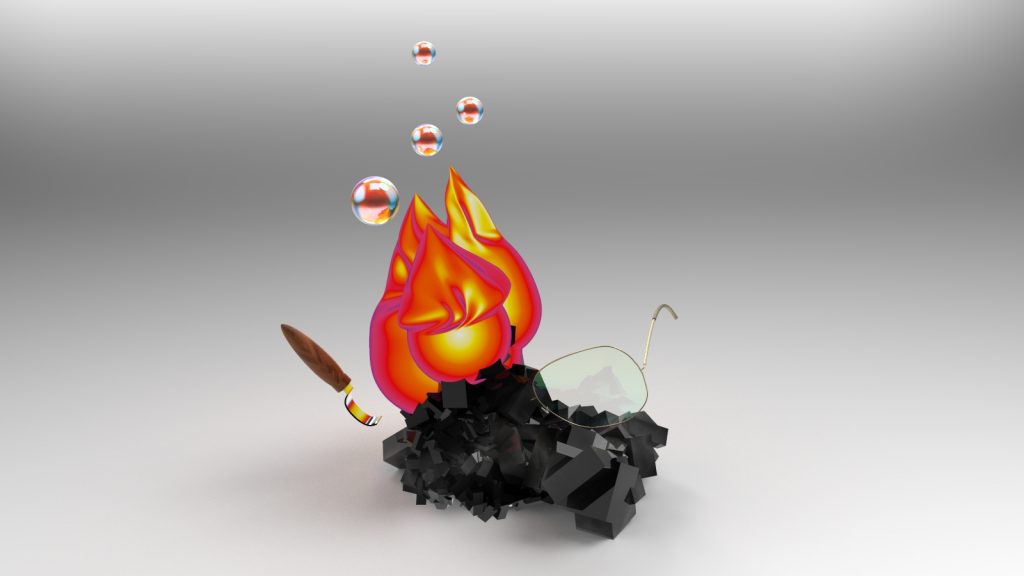

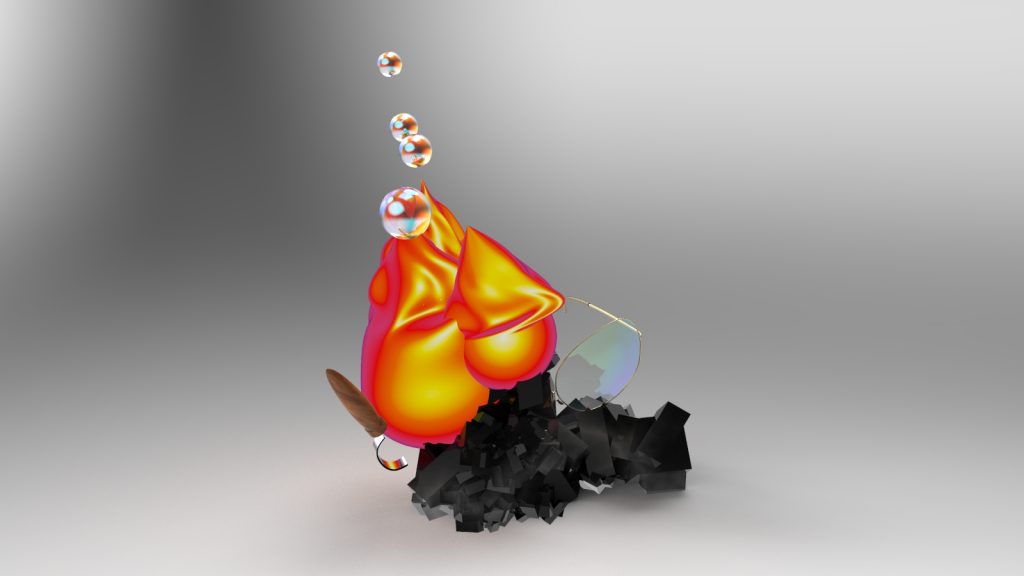

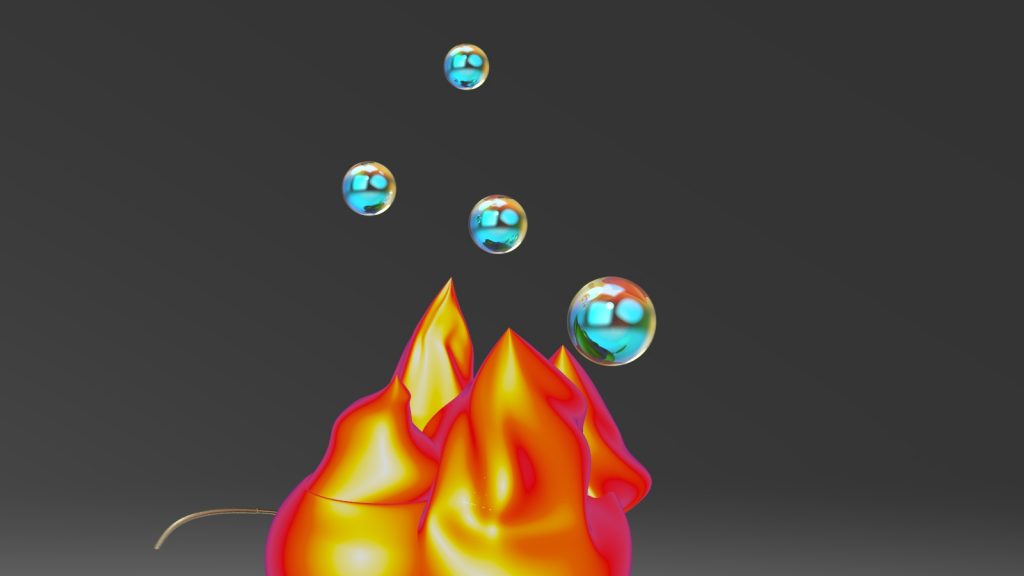

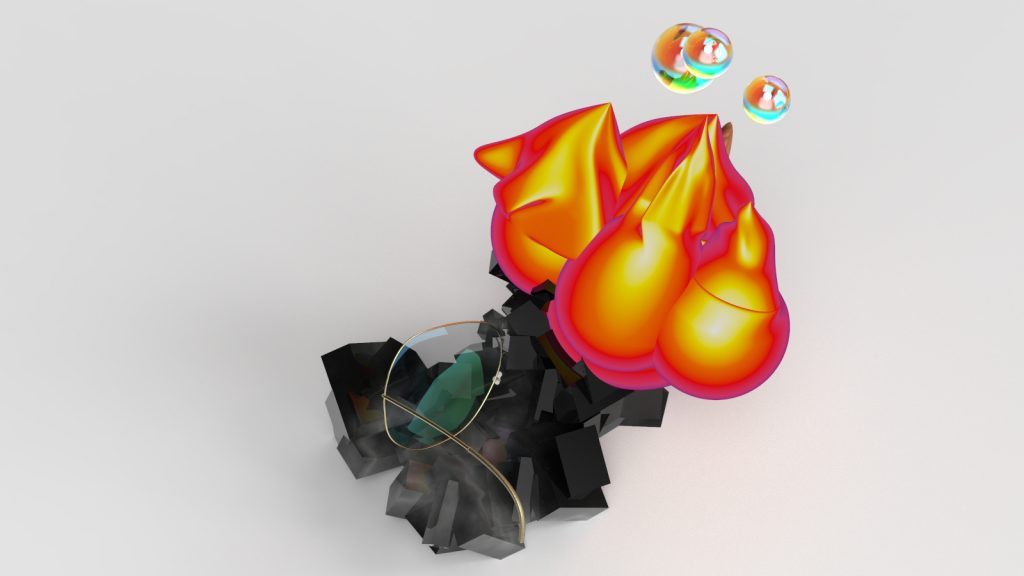

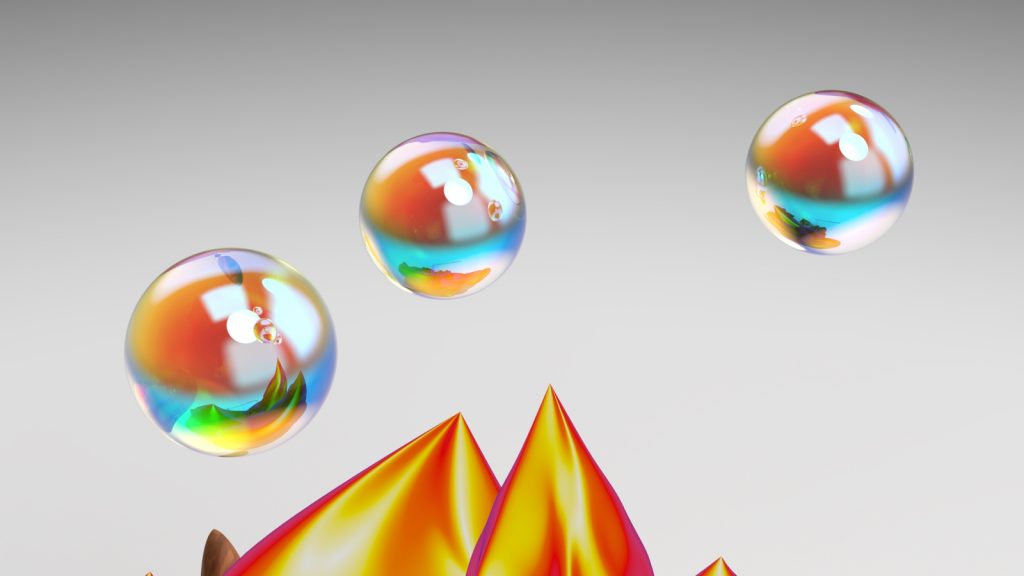

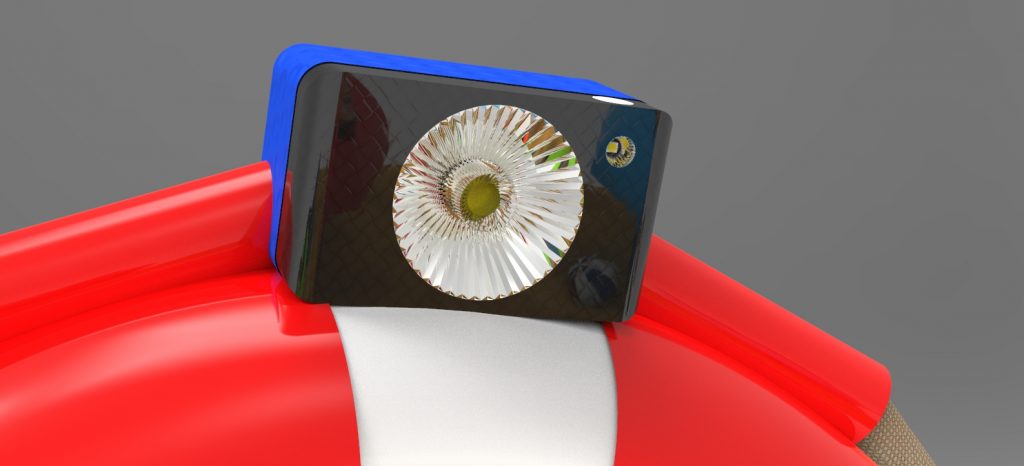

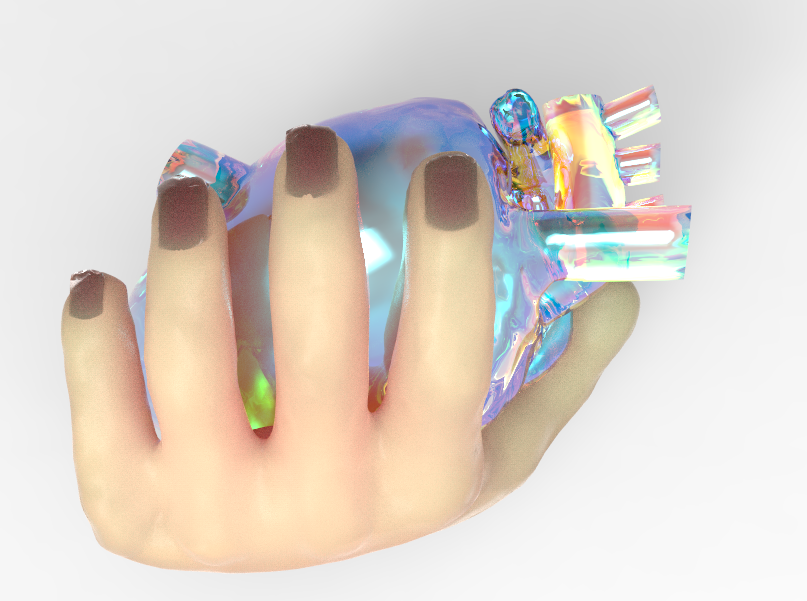

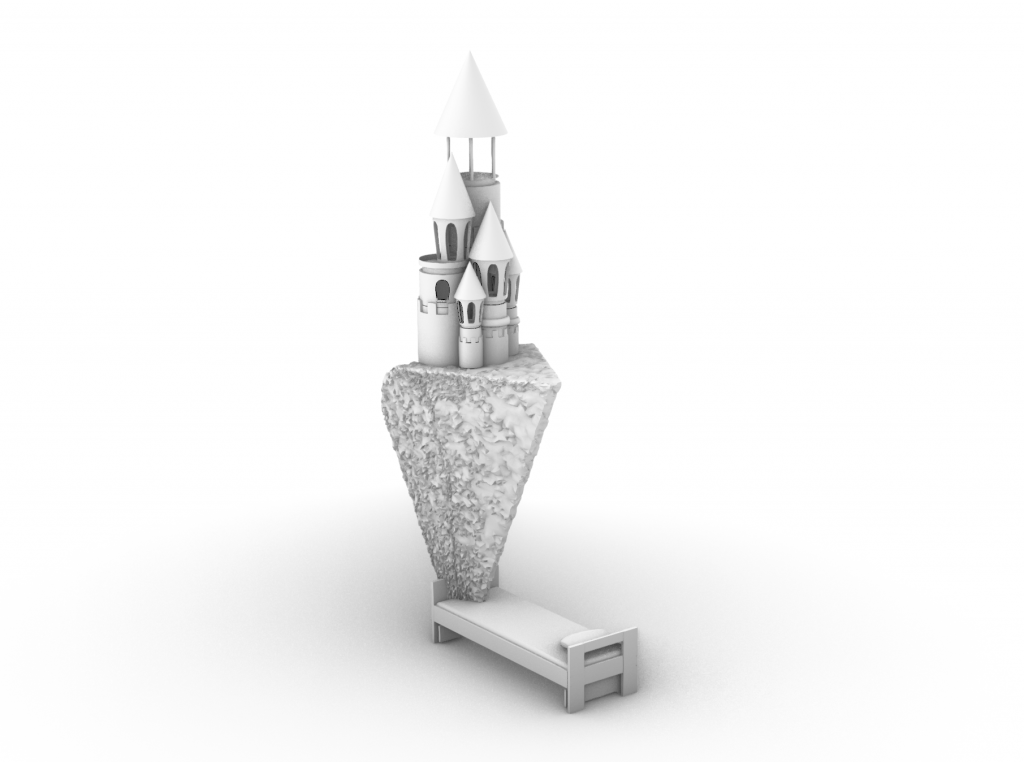

Project 3 Keyshot Renders – Rachel Michael

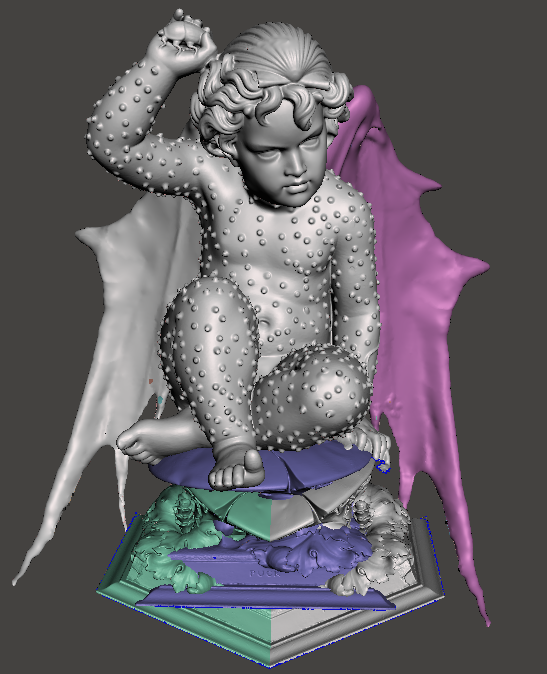

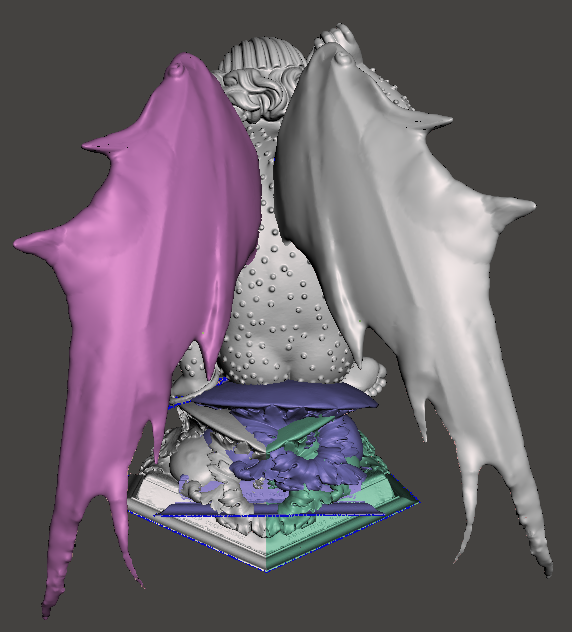

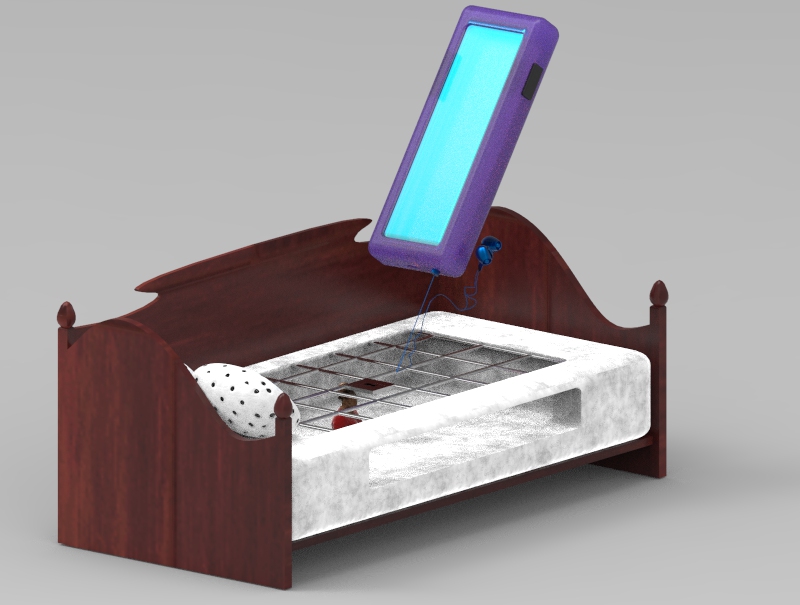

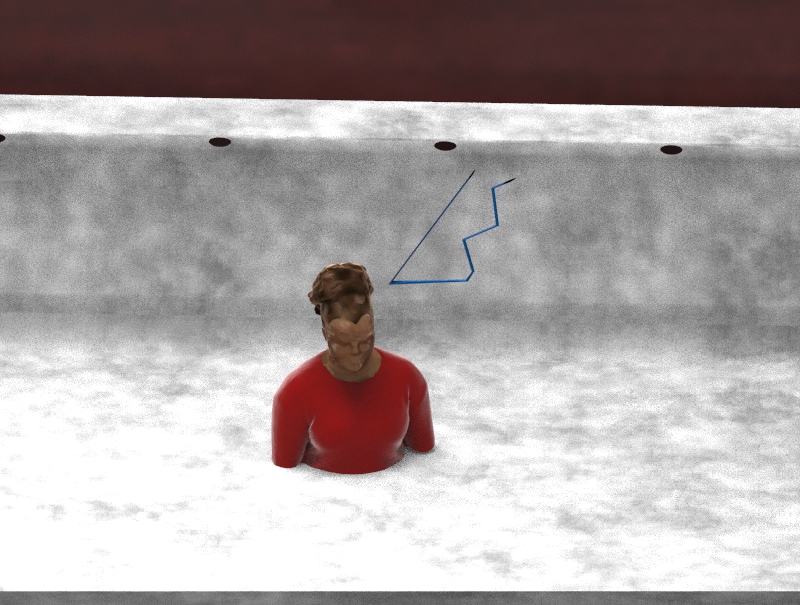

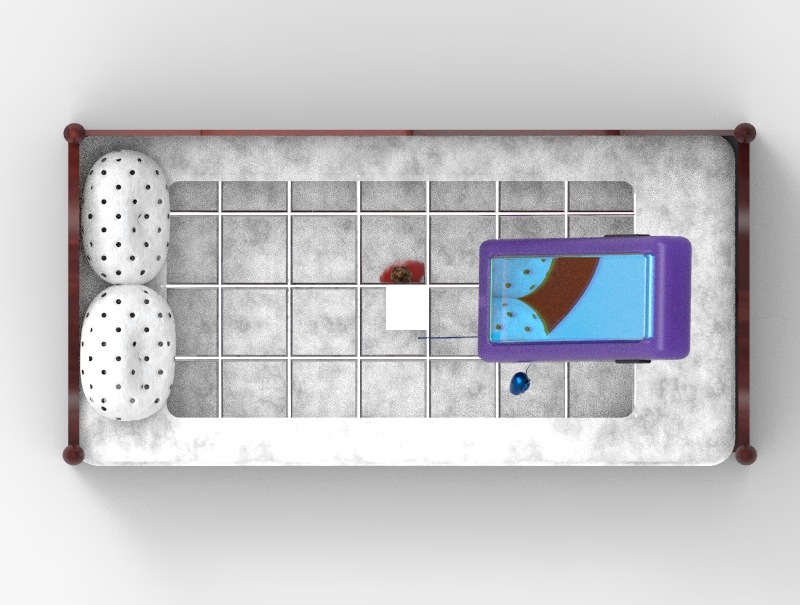

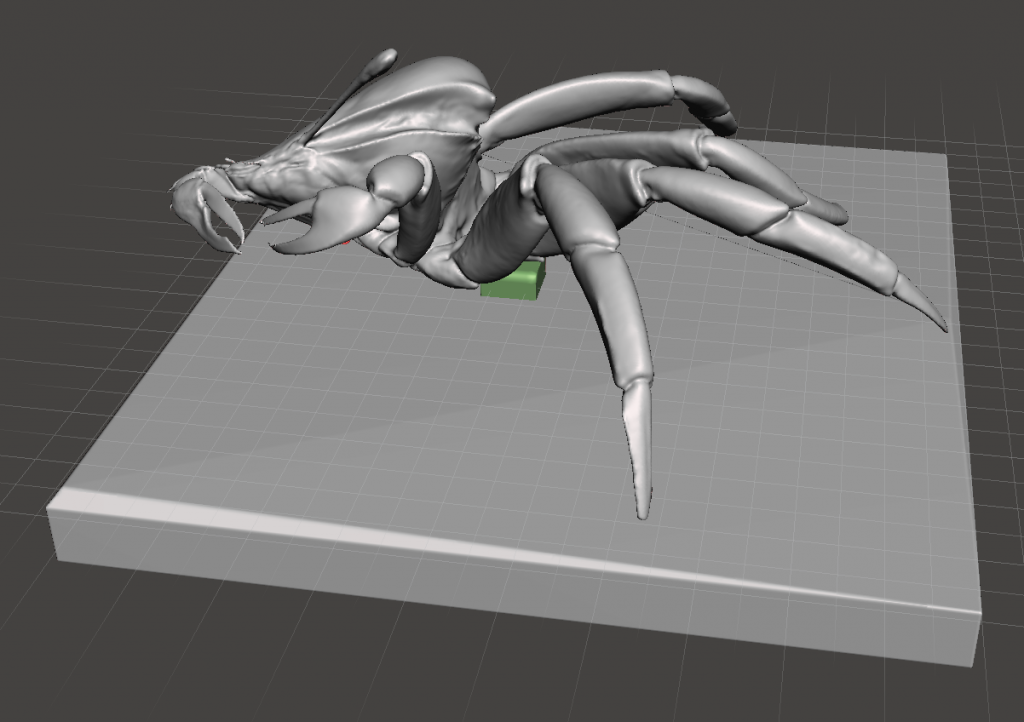

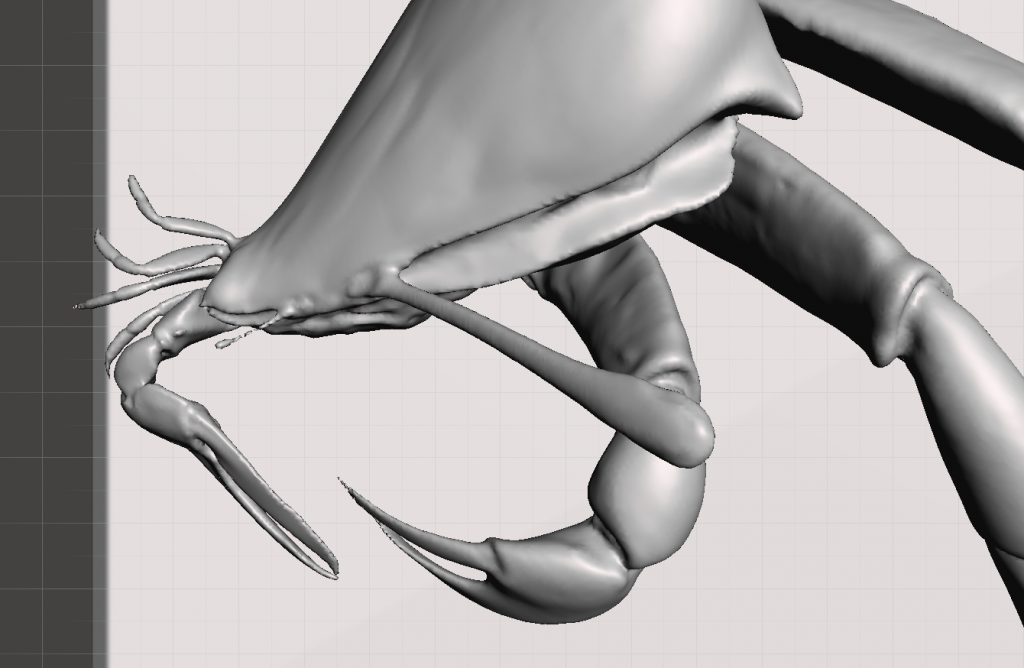

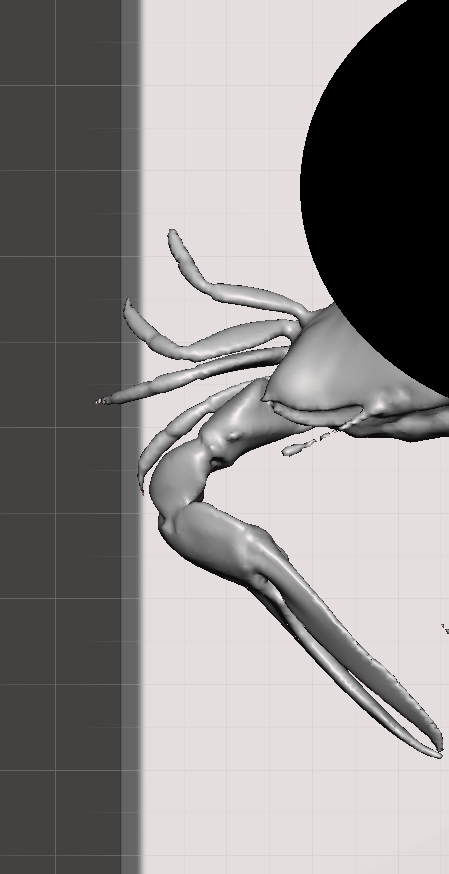

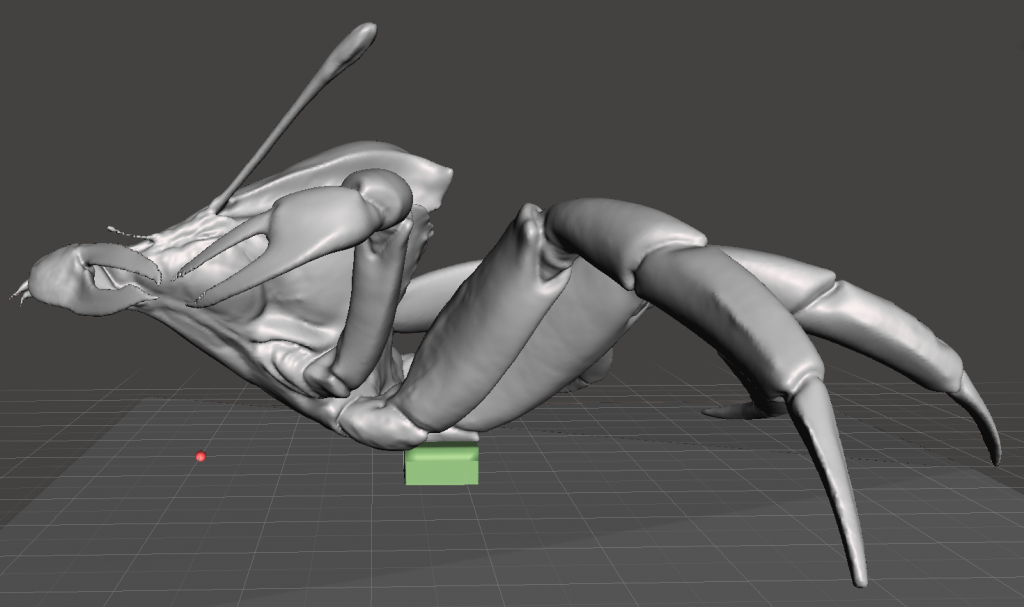

Project 4

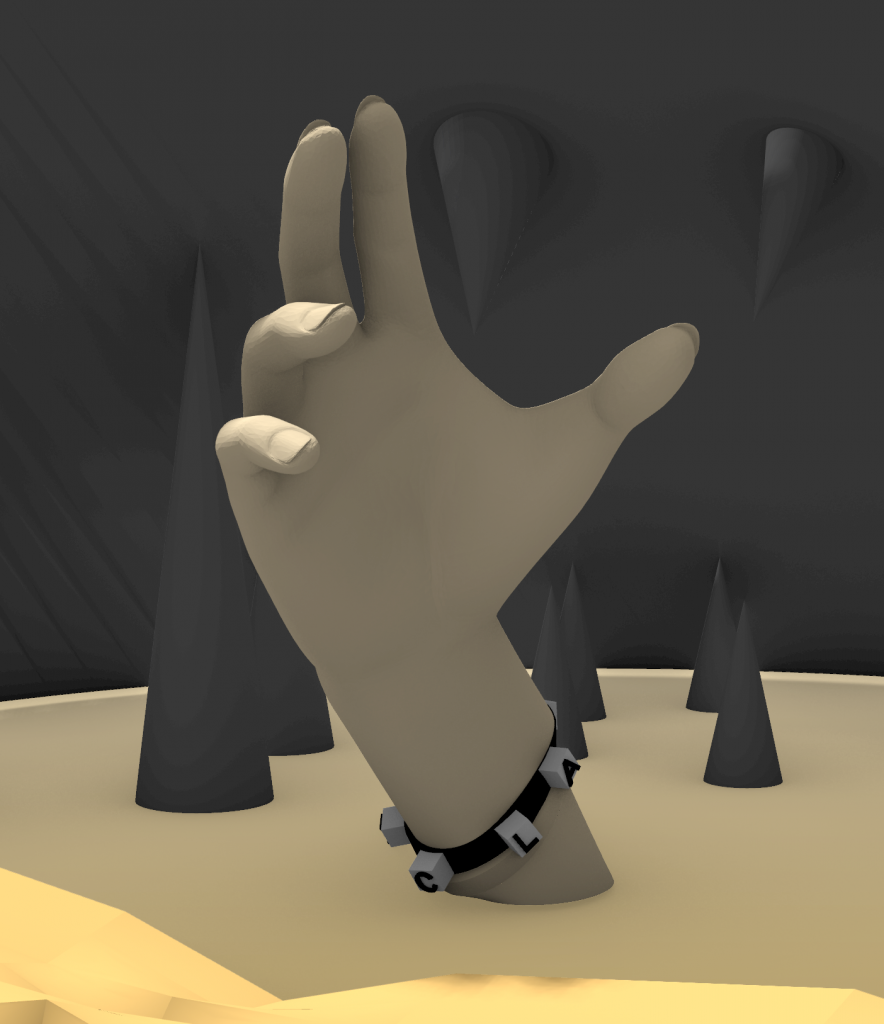

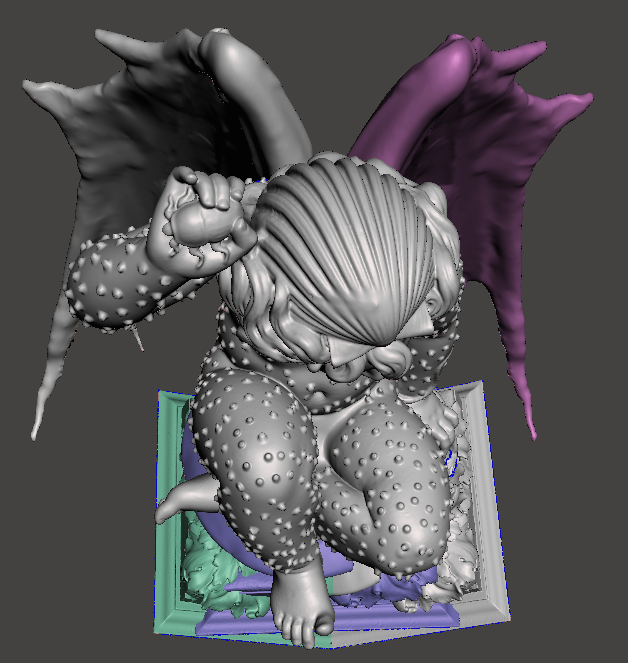

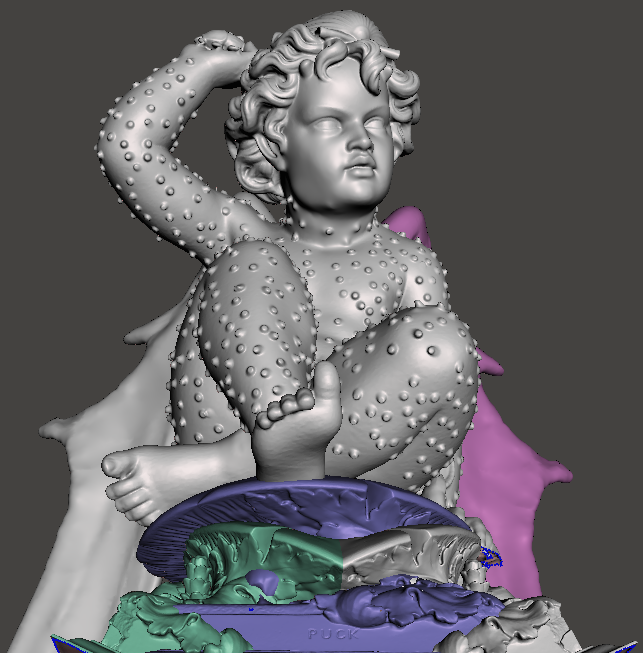

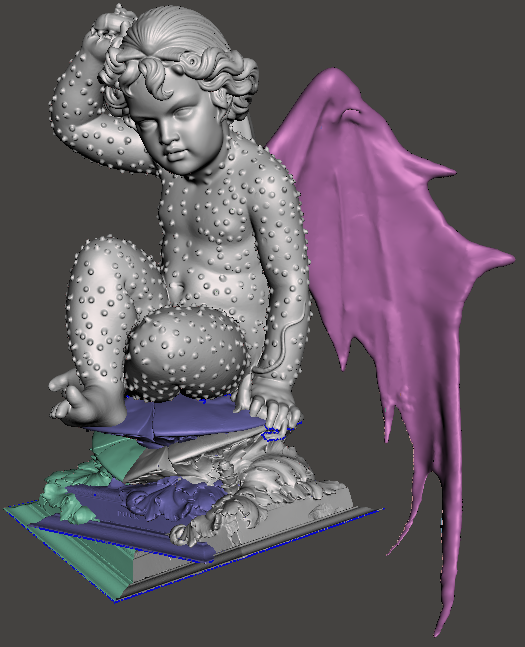

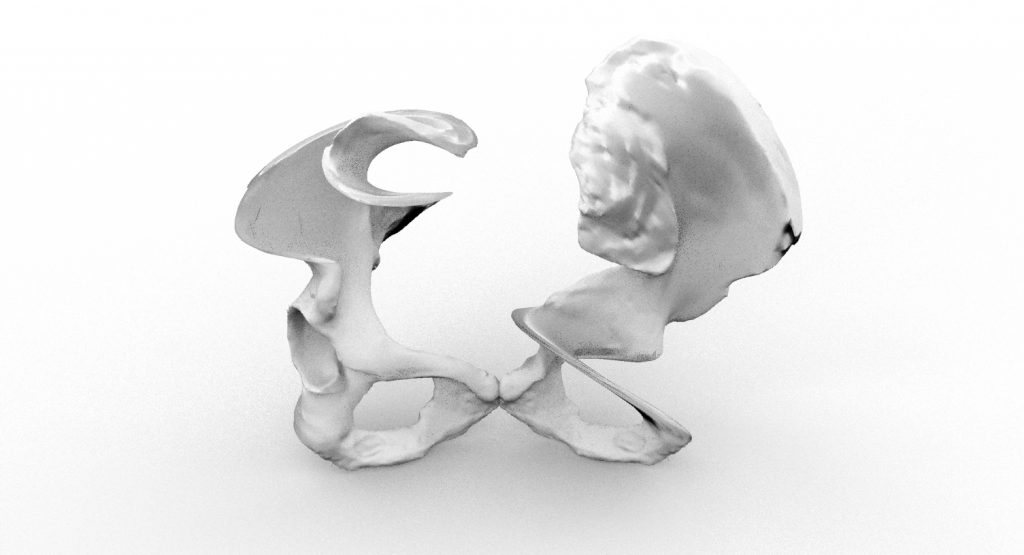

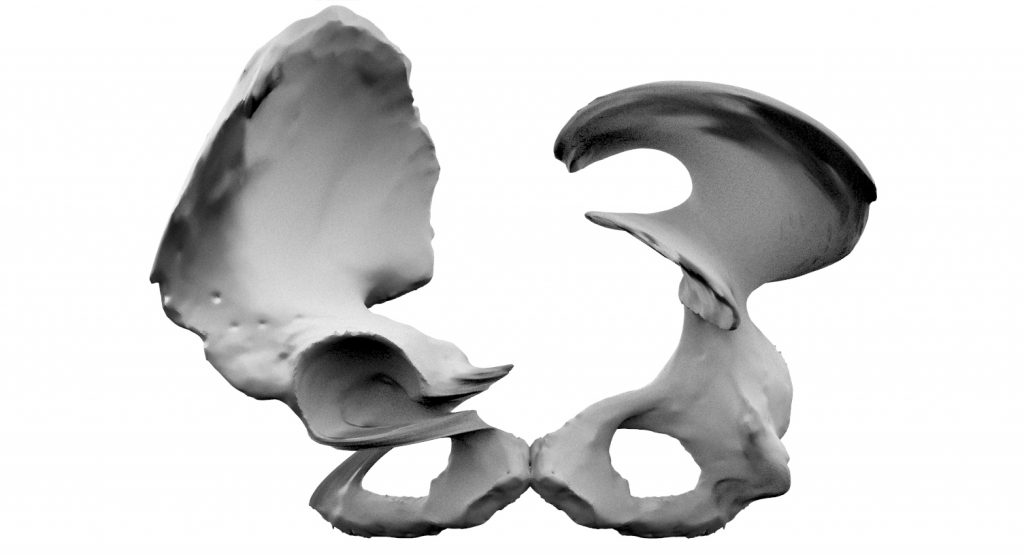

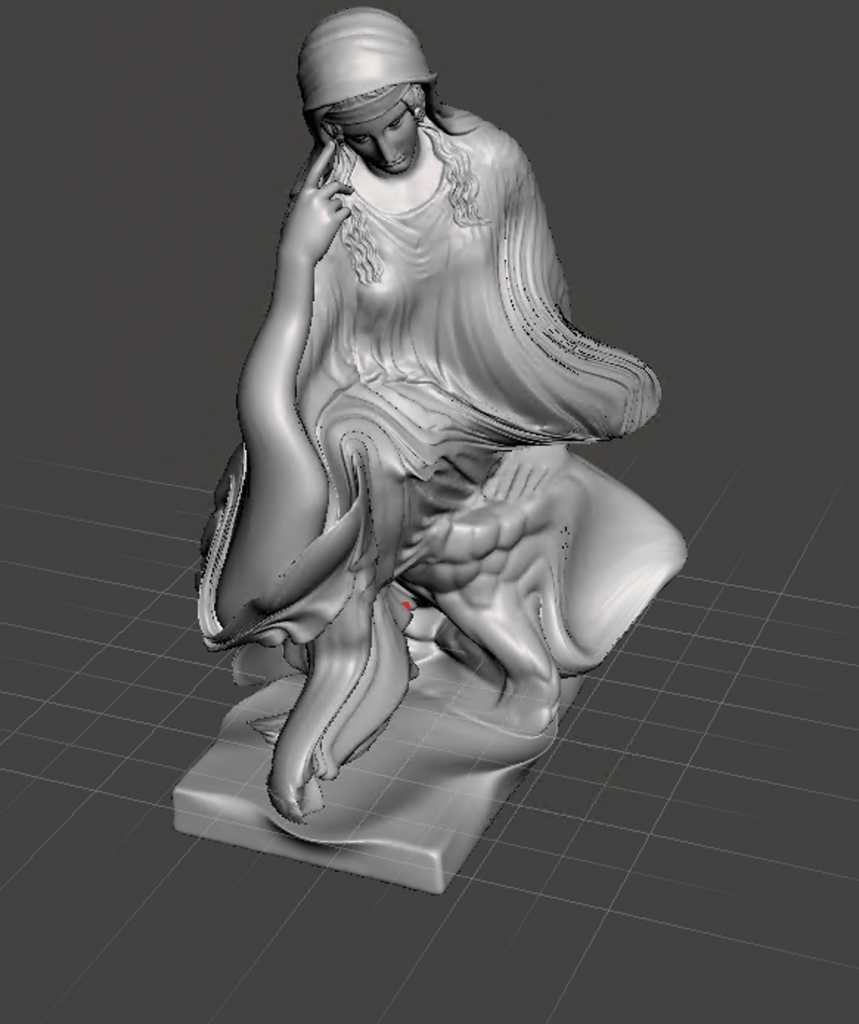

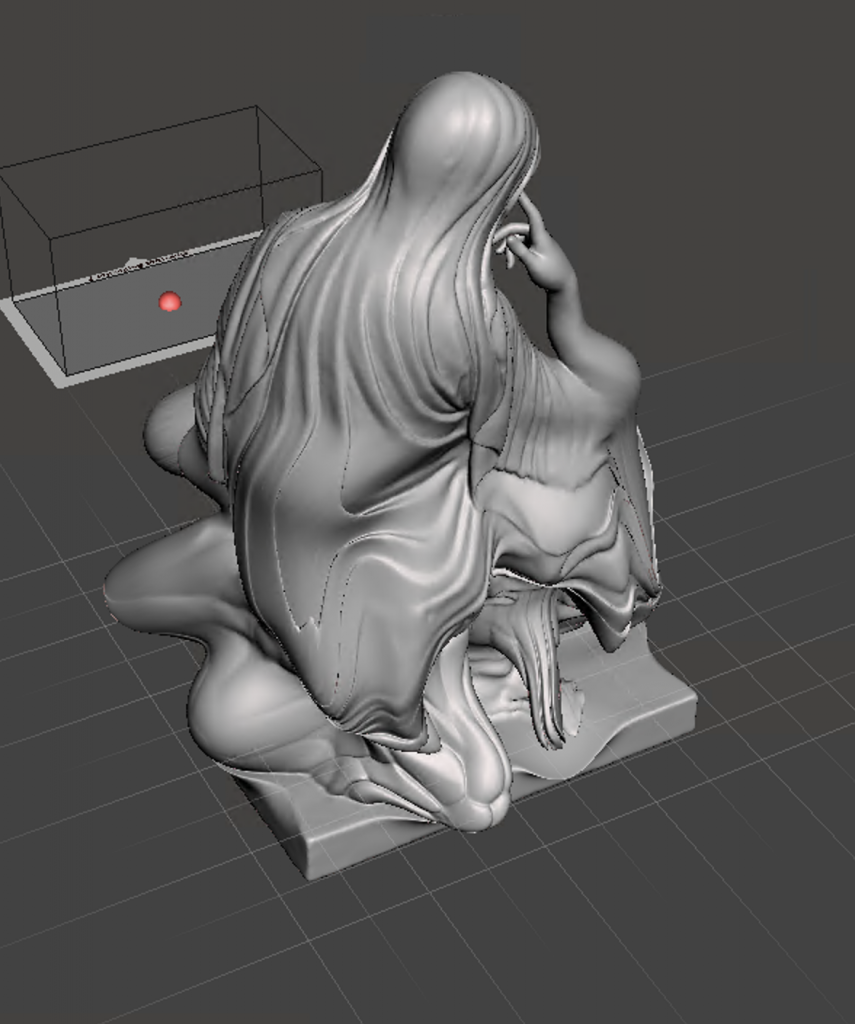

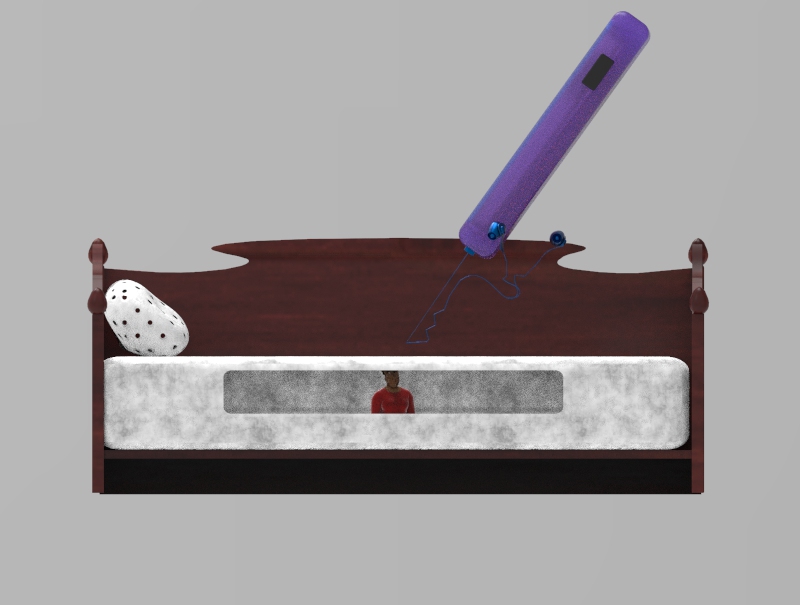

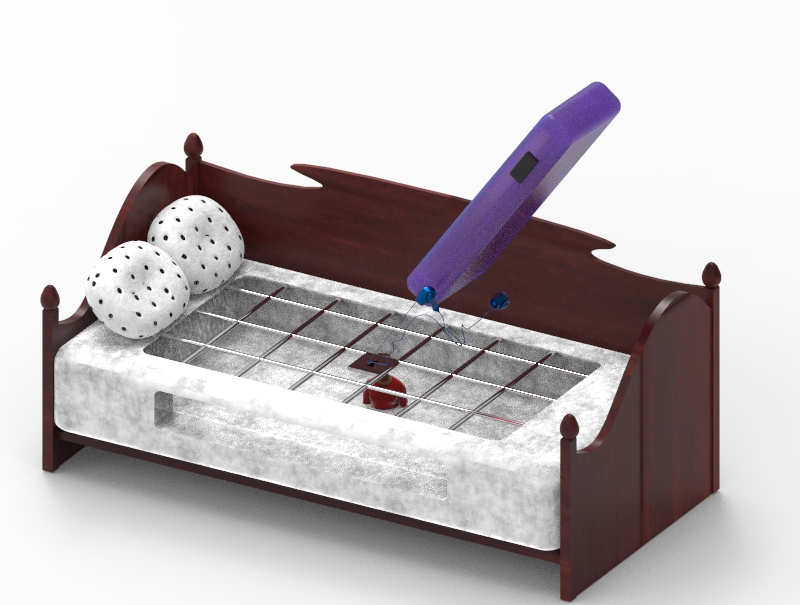

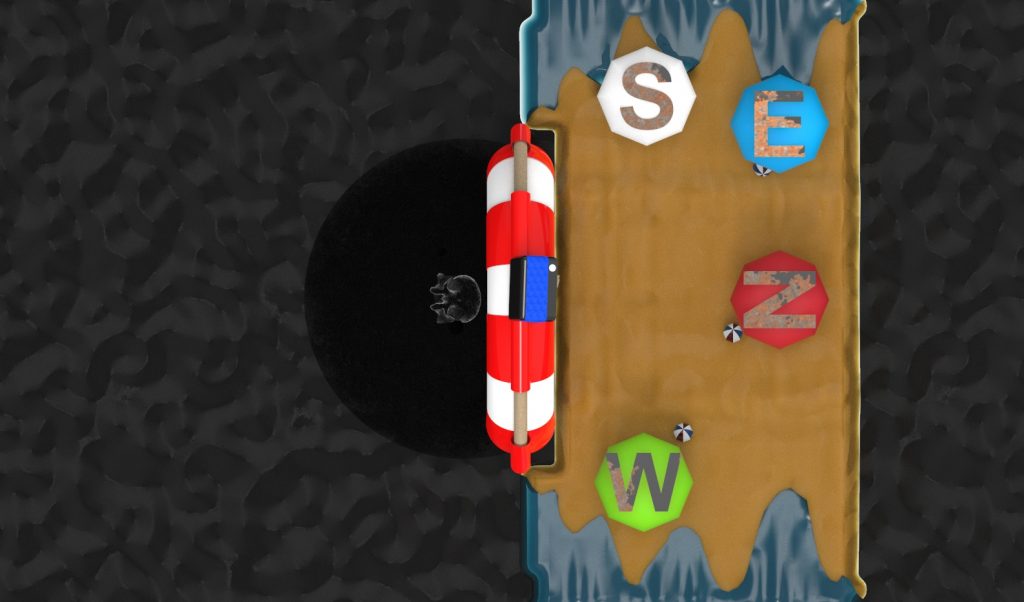

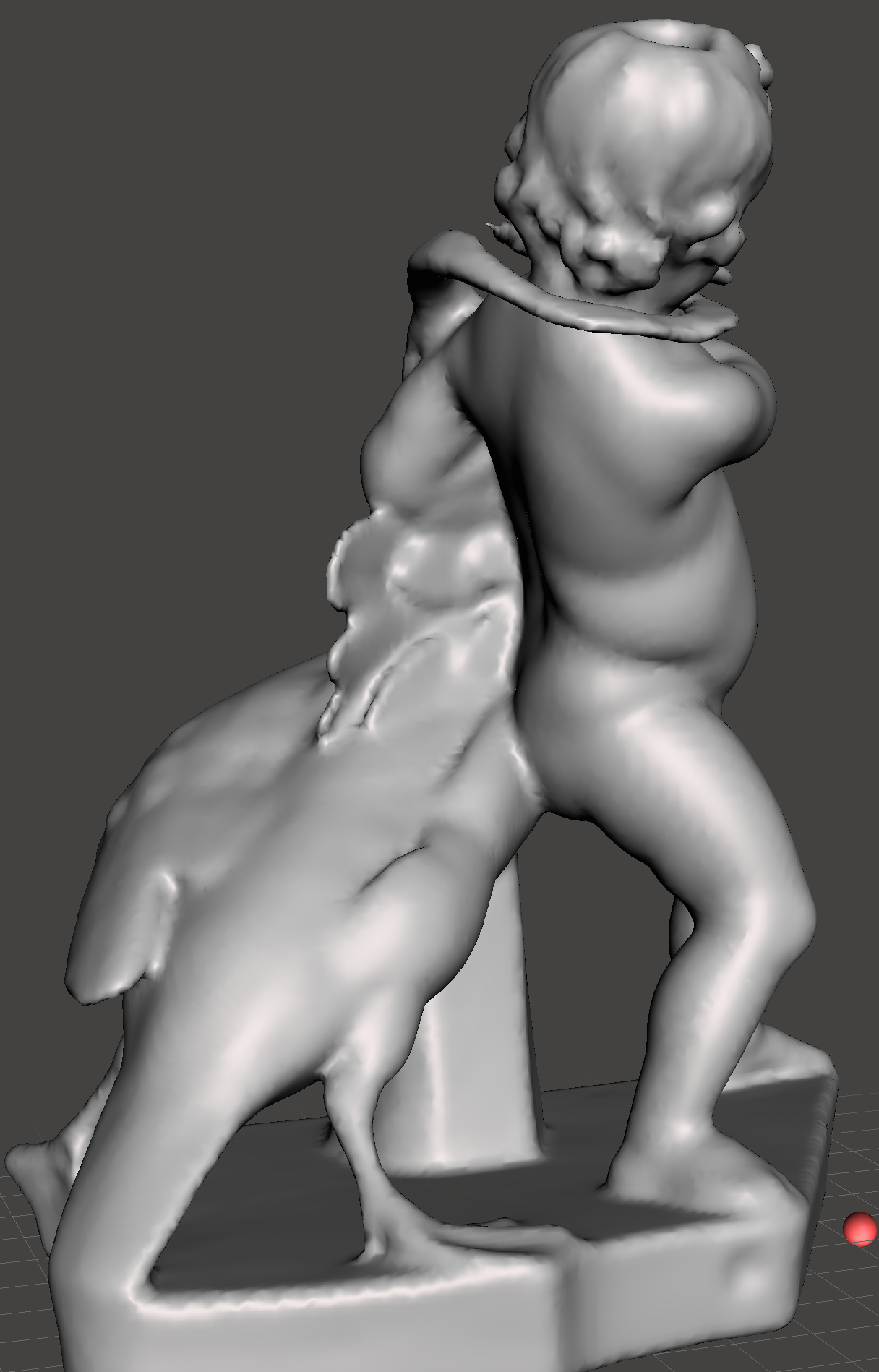

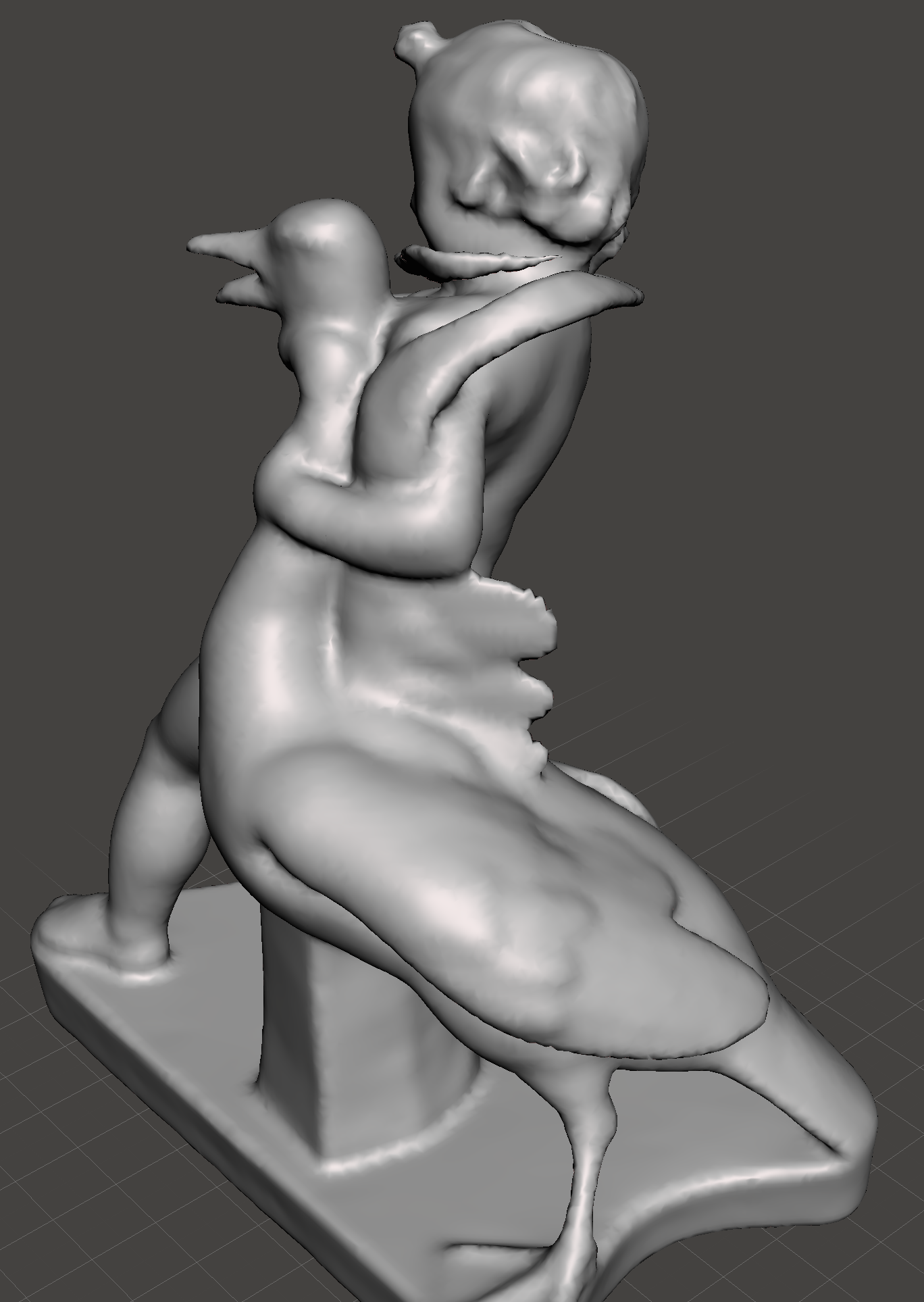

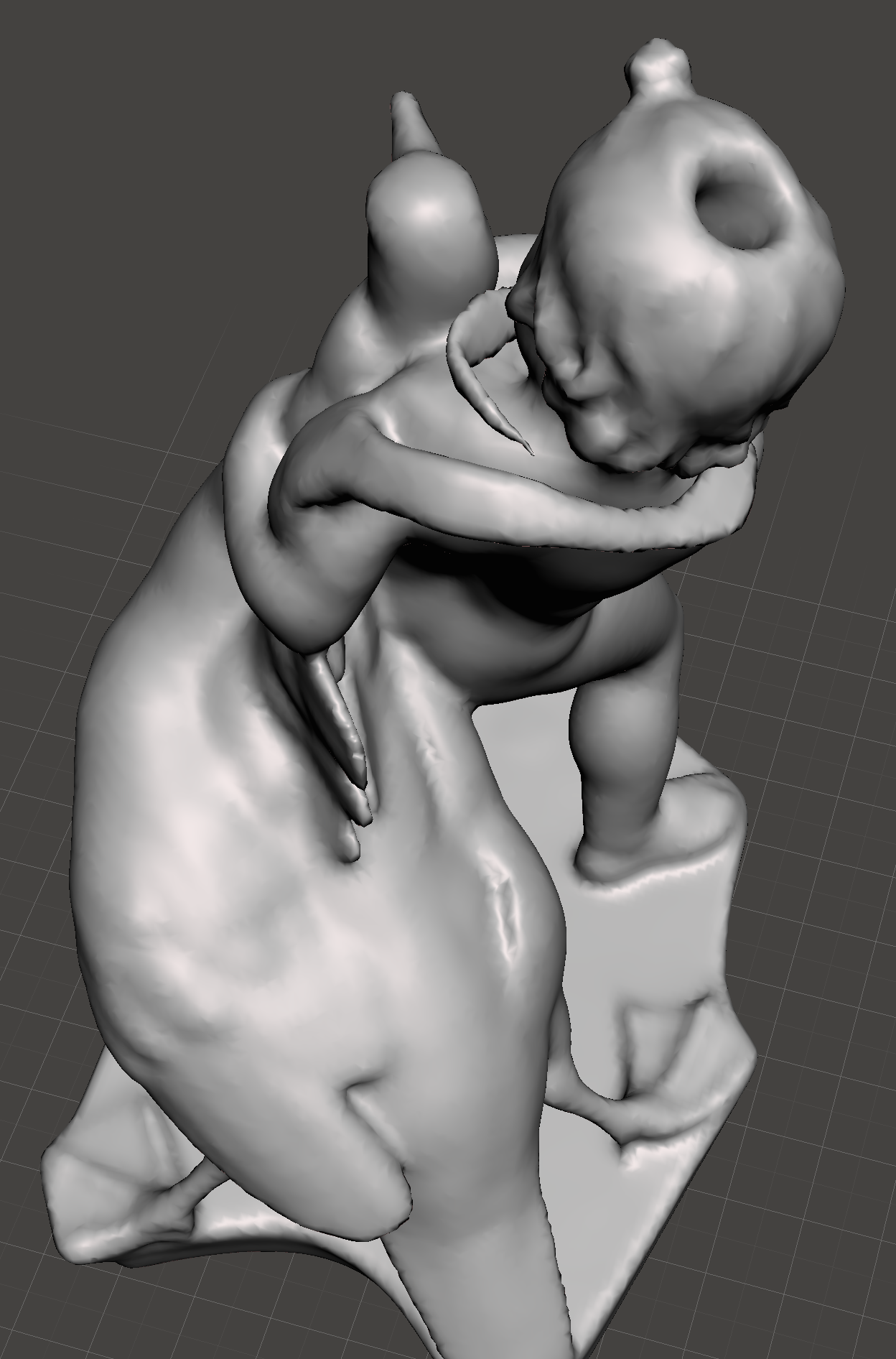

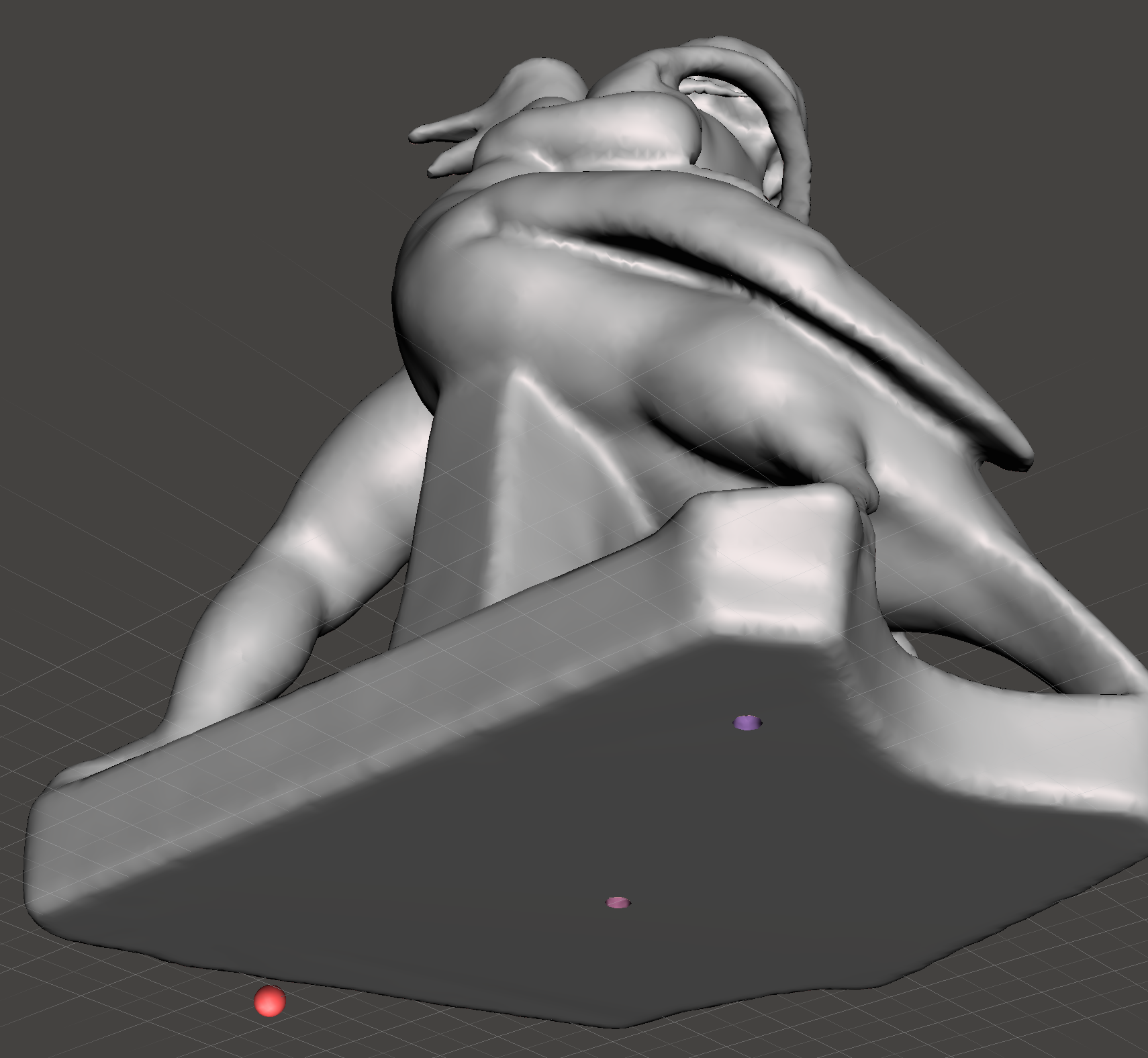

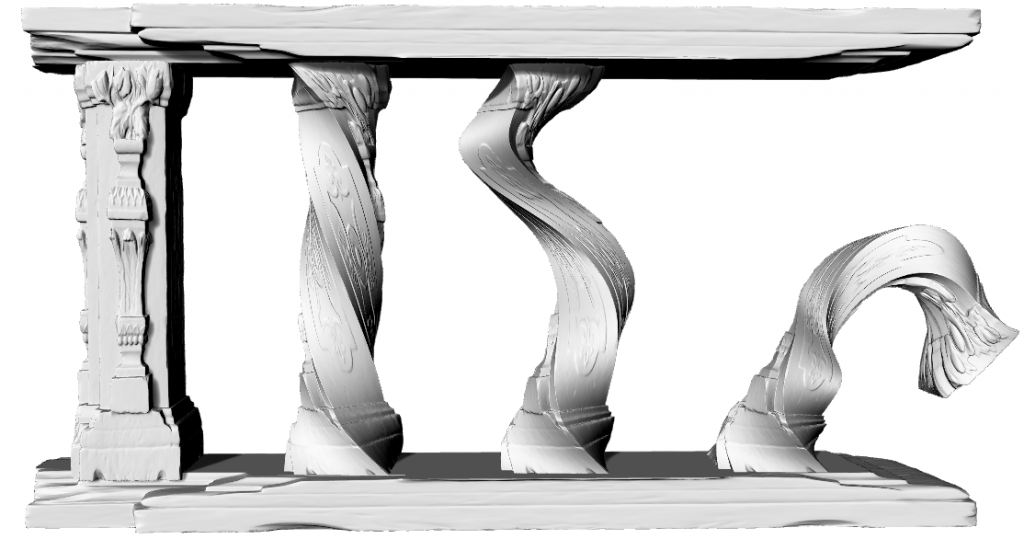

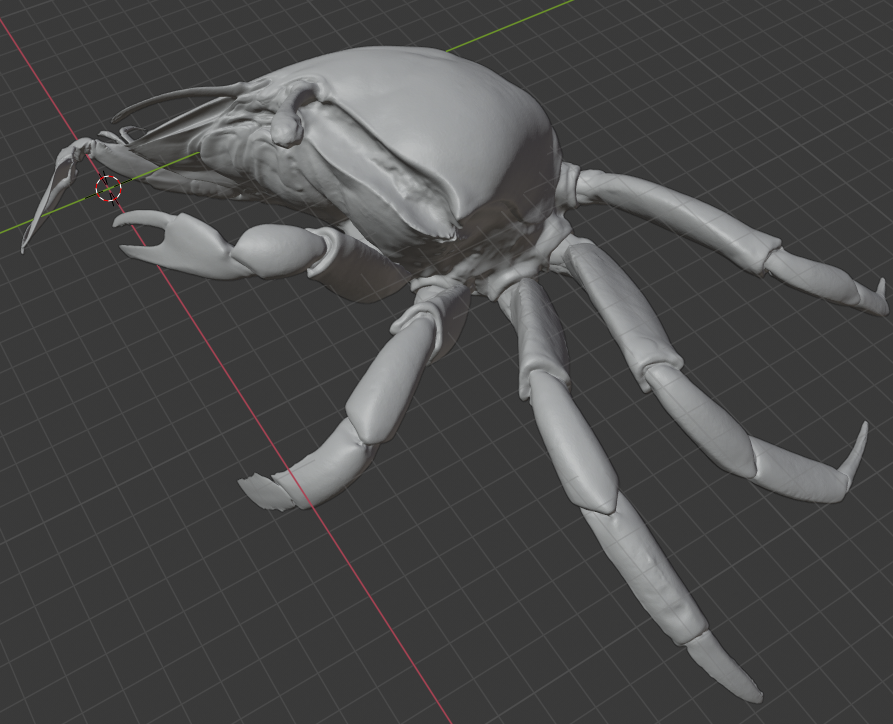

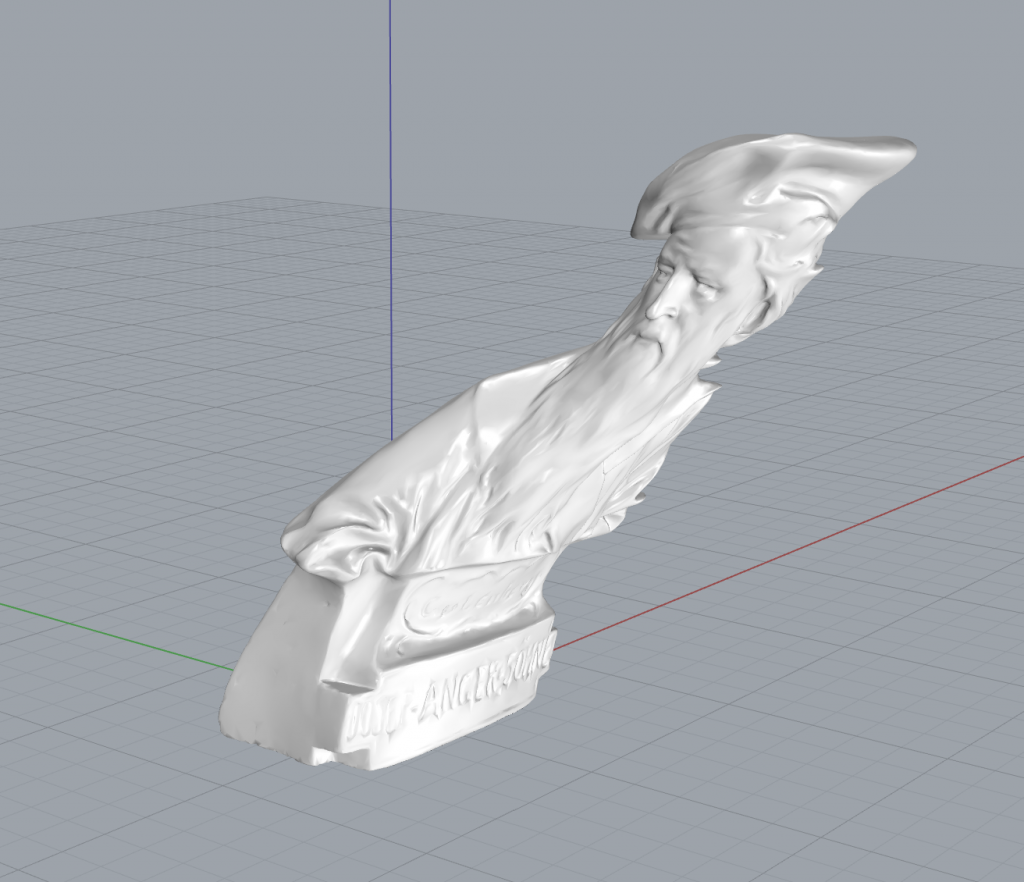

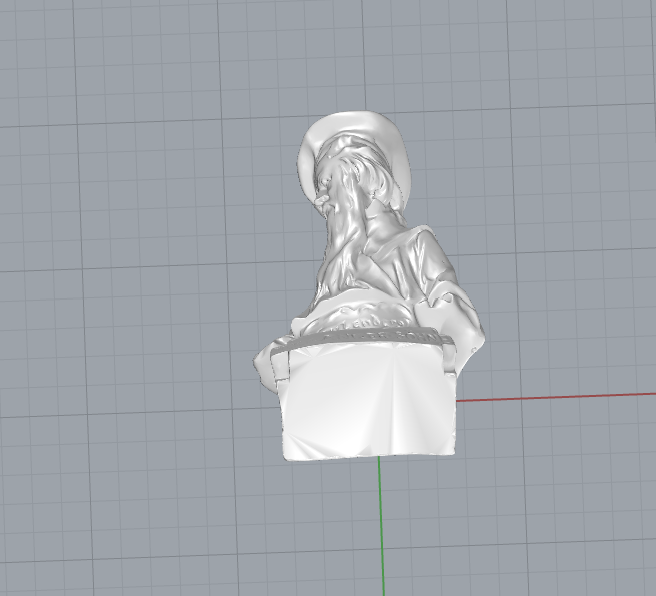

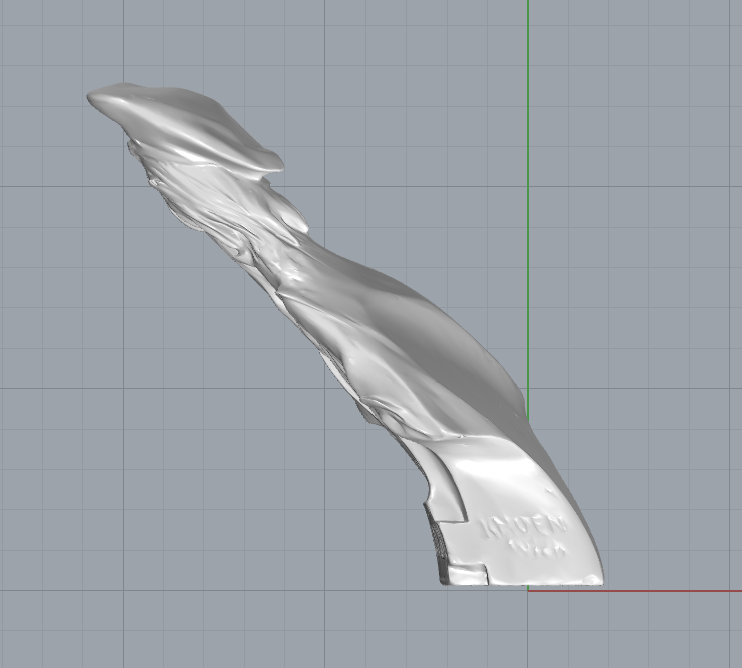

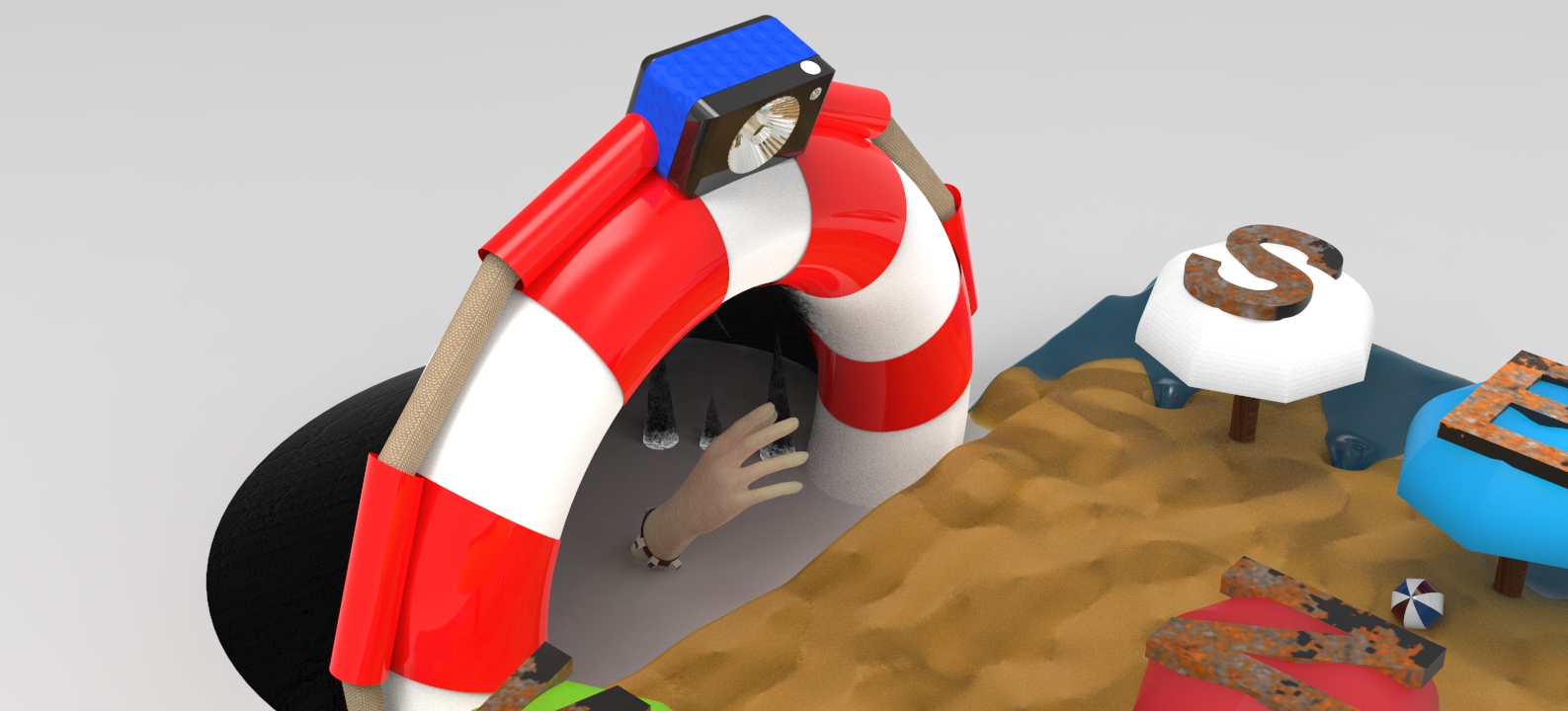

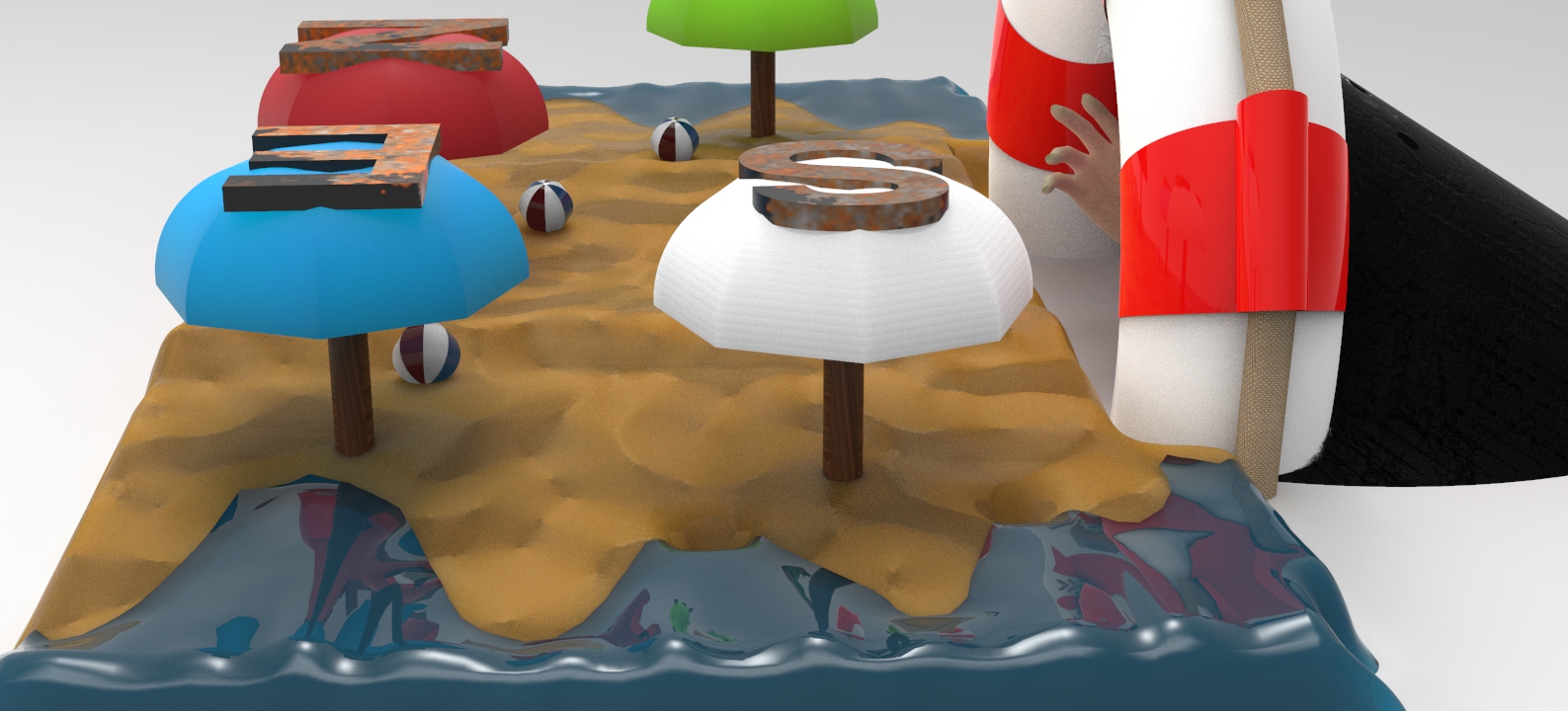

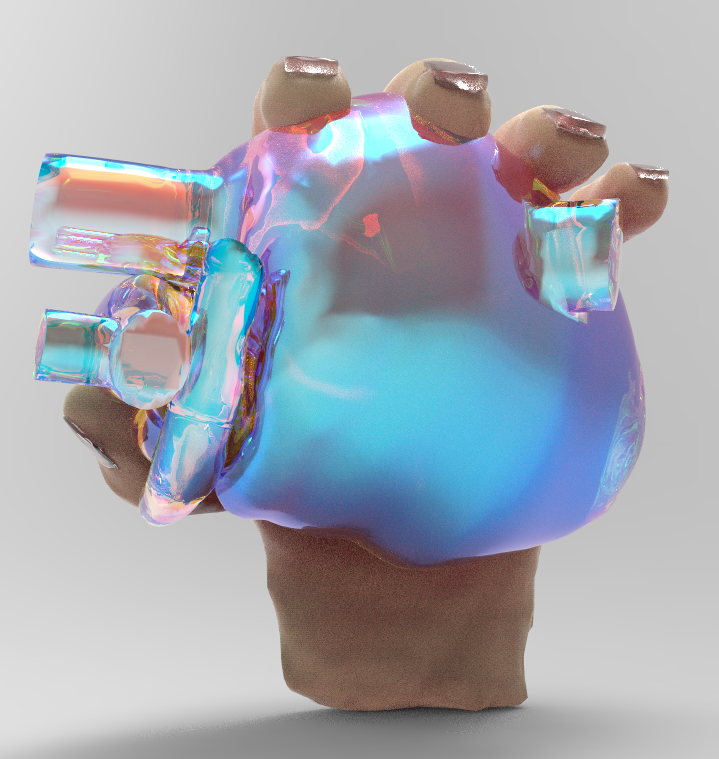

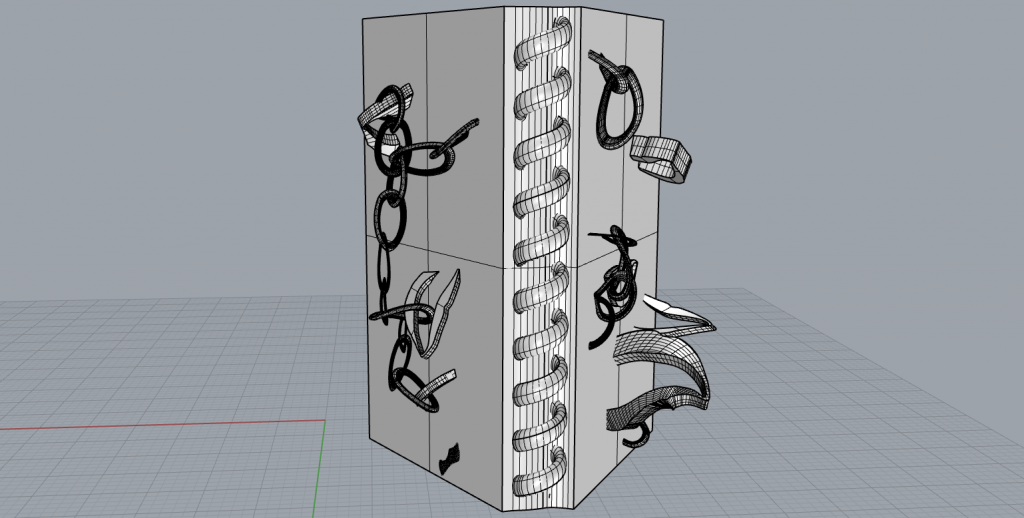

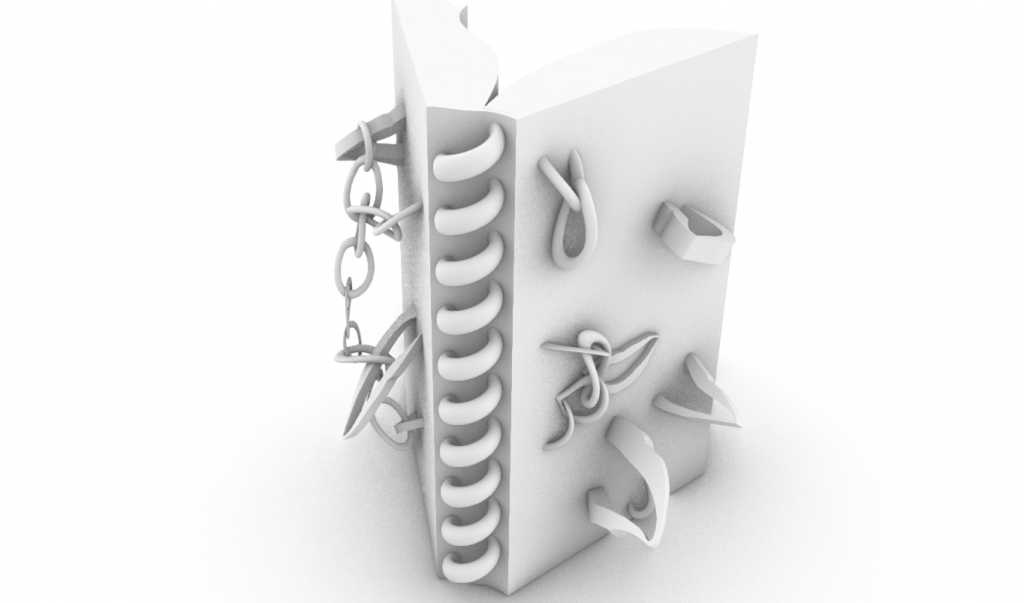

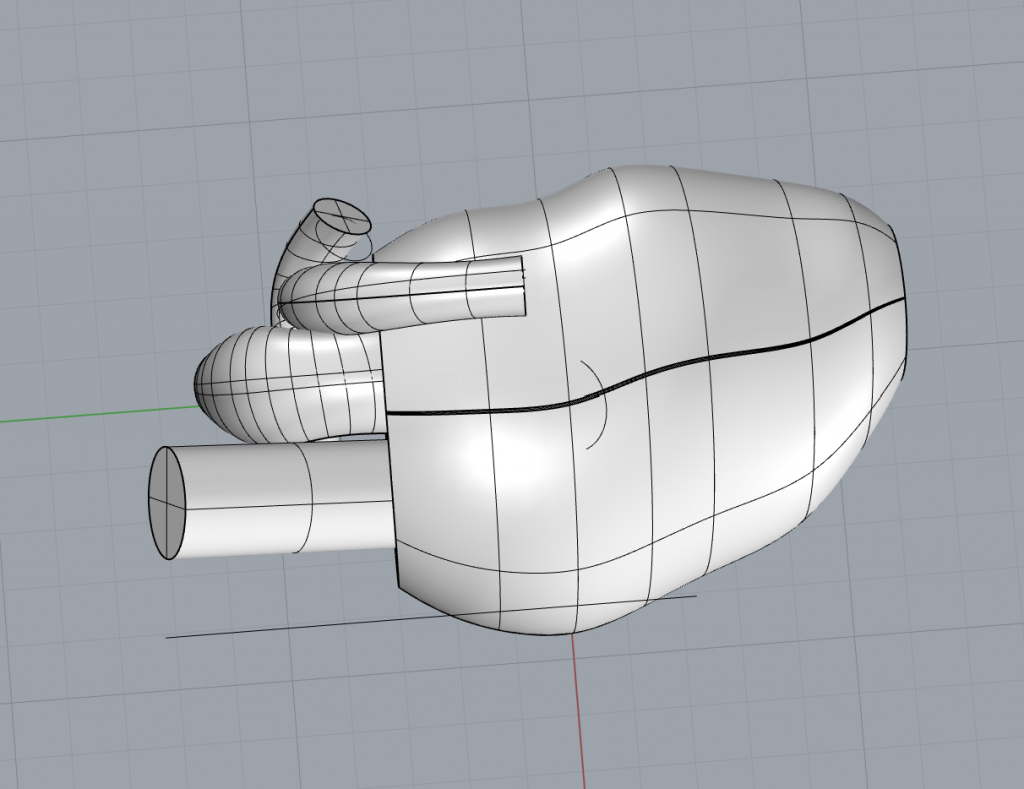

Distortion was initially accomplished using a cage edit in conjunction with other tools, however due to crashing problems the cage edit was swapped with a lattice distortion in Blender 2.8, which is near identical to the cage edit function in Rhino, while fine tuning, solidifying, and other tweaks were accomplished in Meshmixer

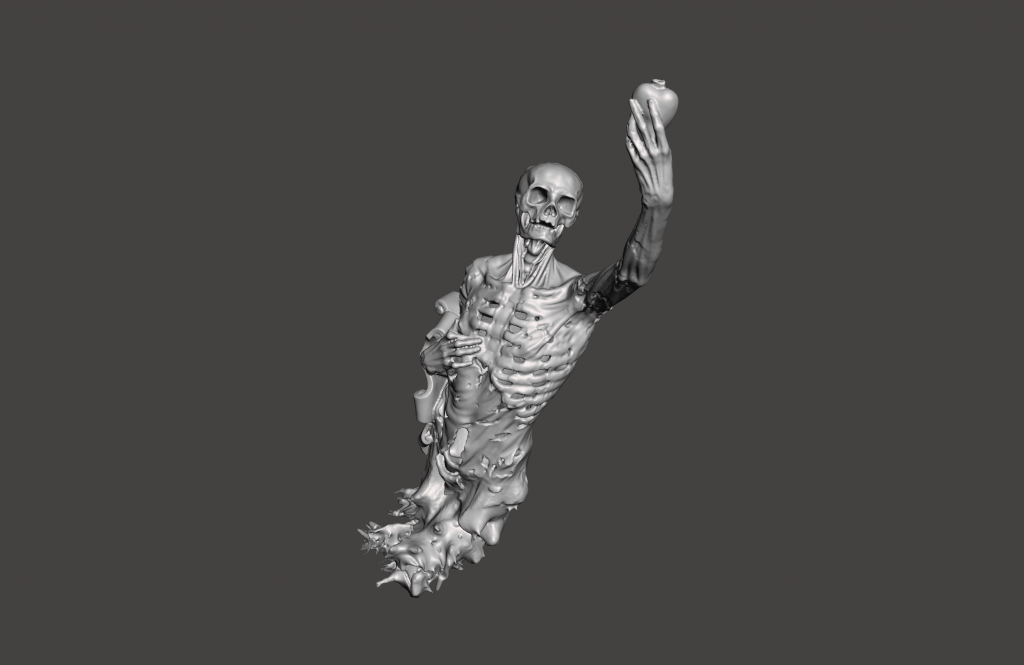

Project 4 – Rachel Michael

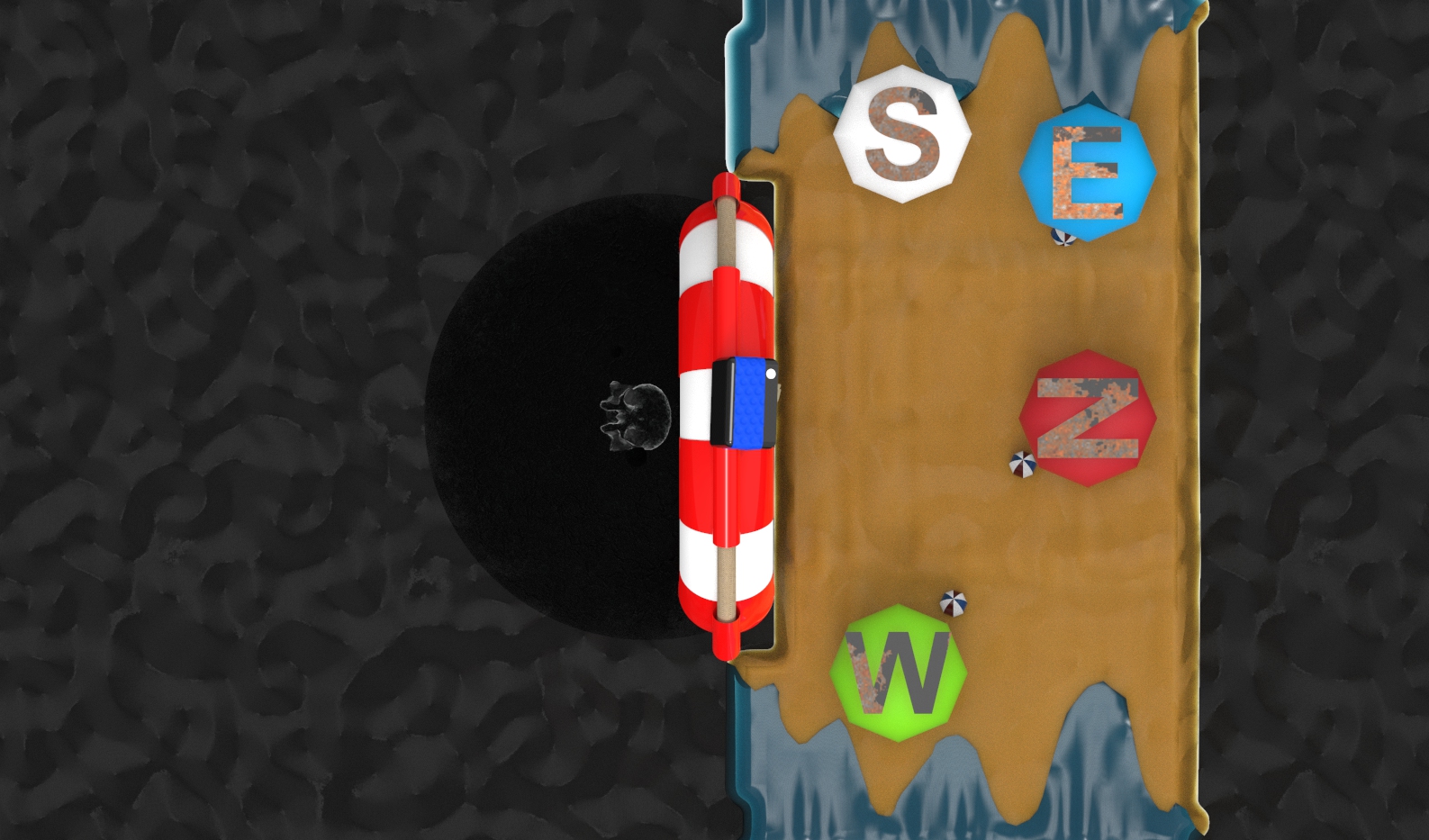

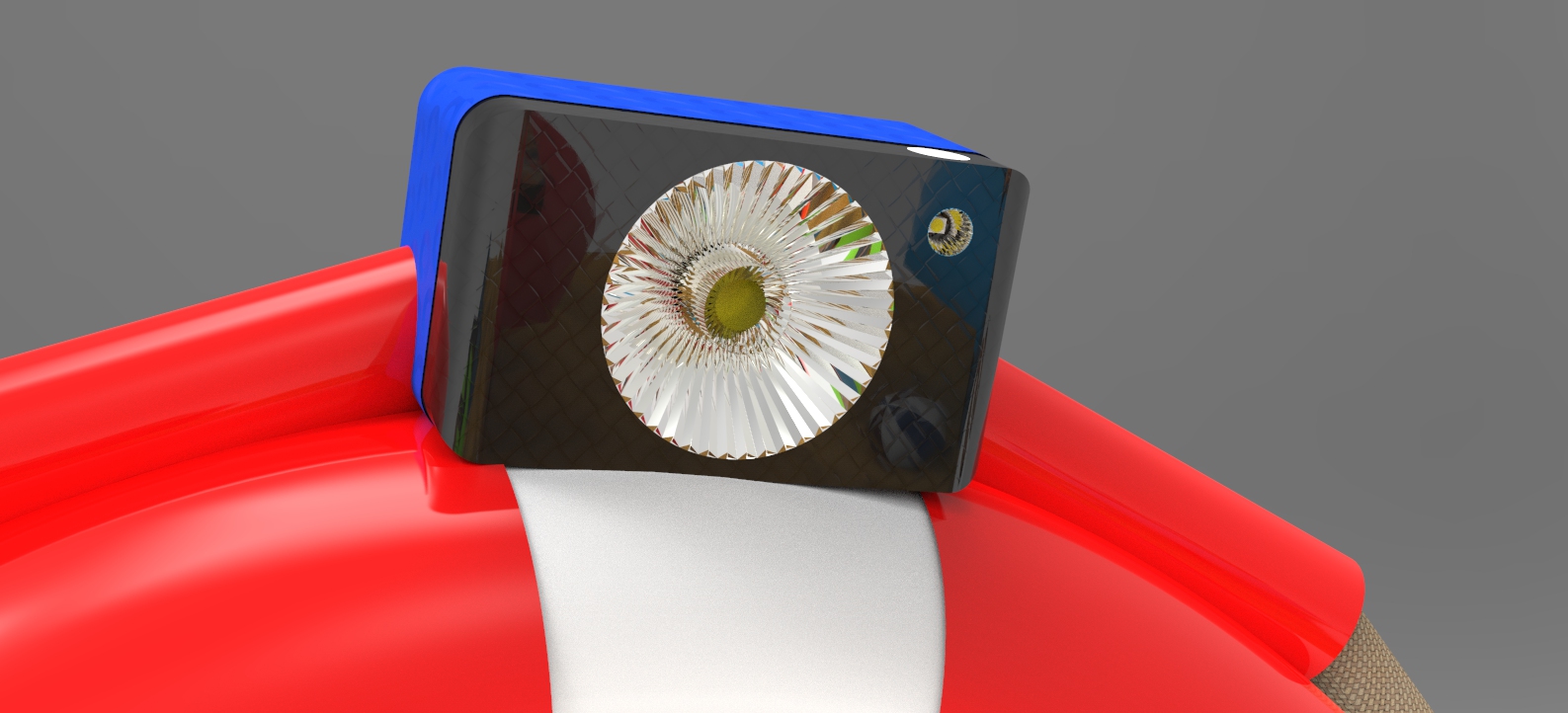

Project 4

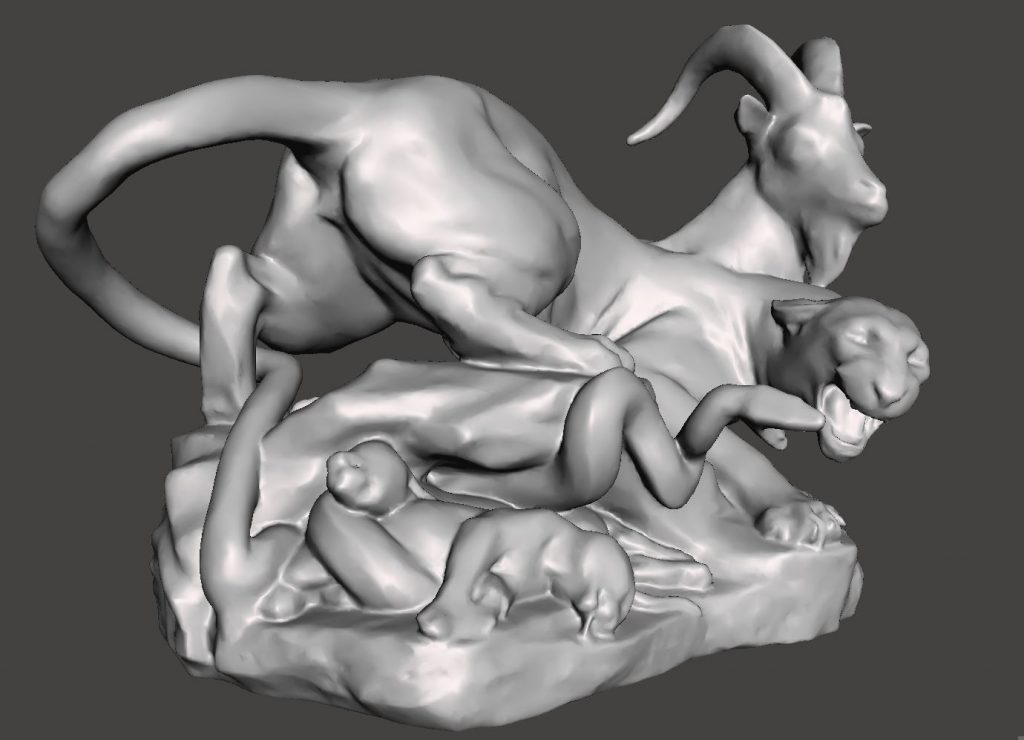

Marisa Morakis, Project 4 Finished Design

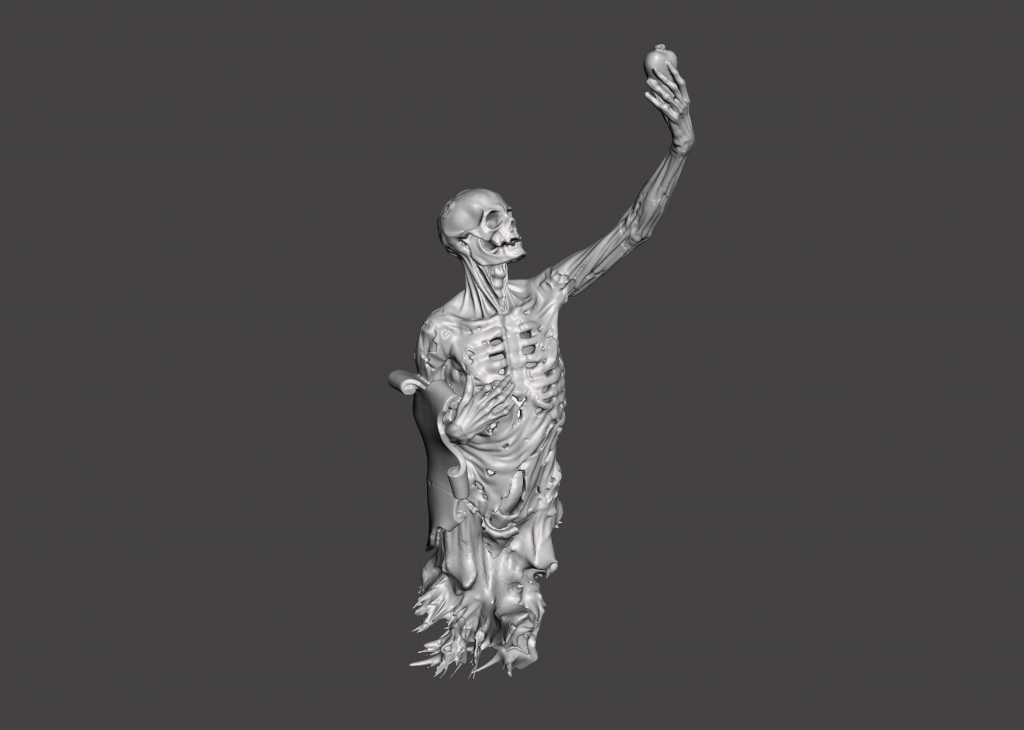

Charles-Project 4

Matt Turconi – Project 4

Amy Lowe-Project 4

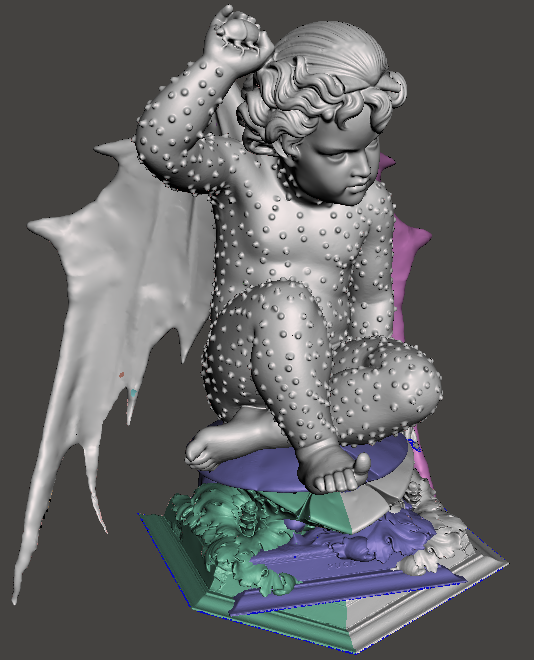

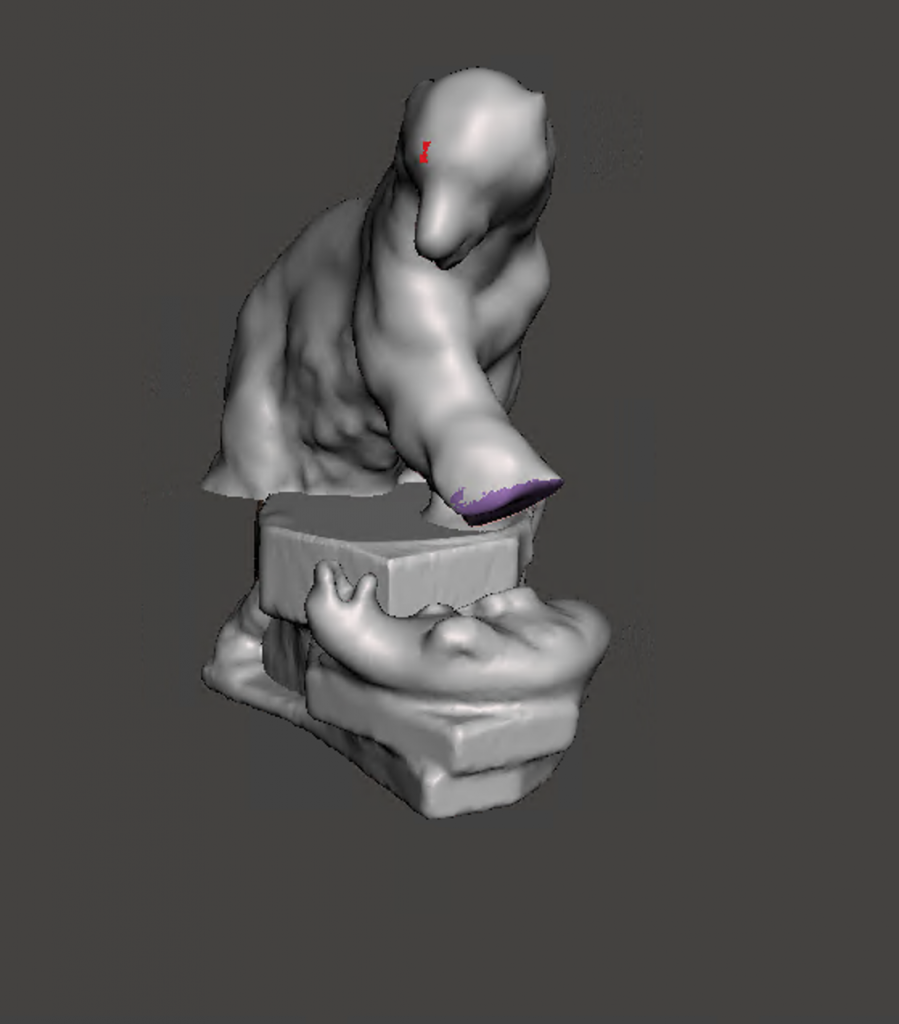

Project 4 Progress

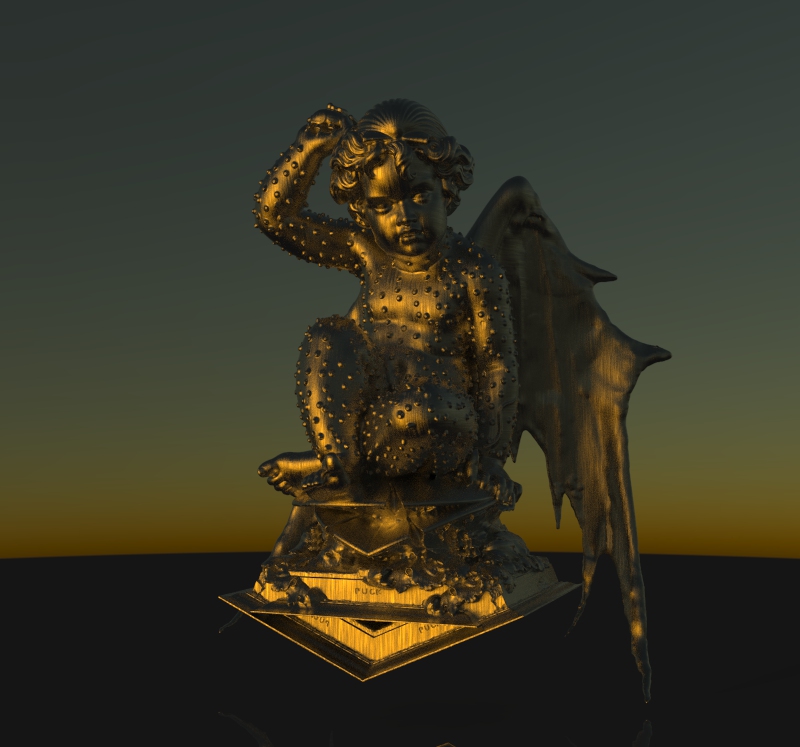

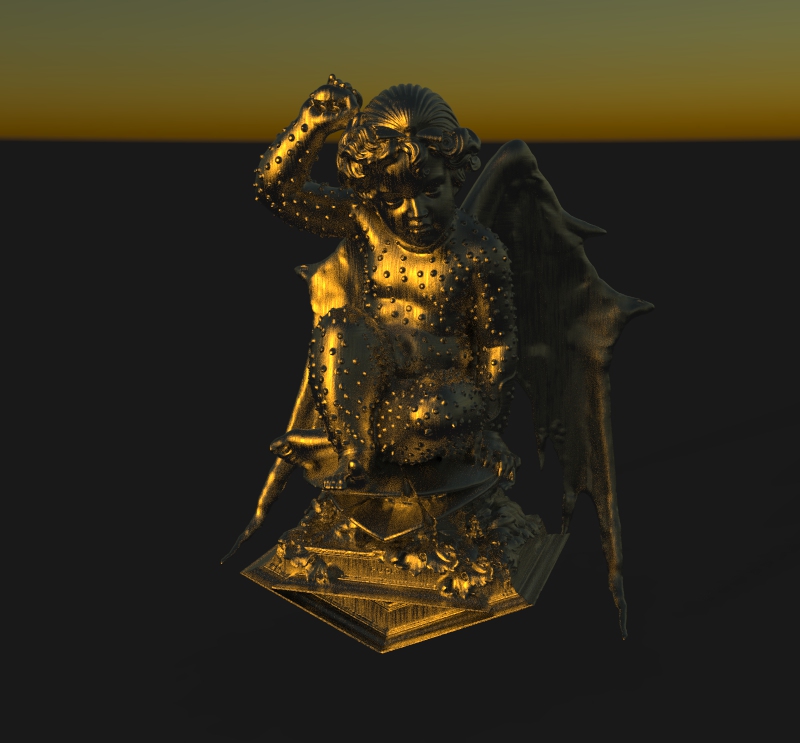

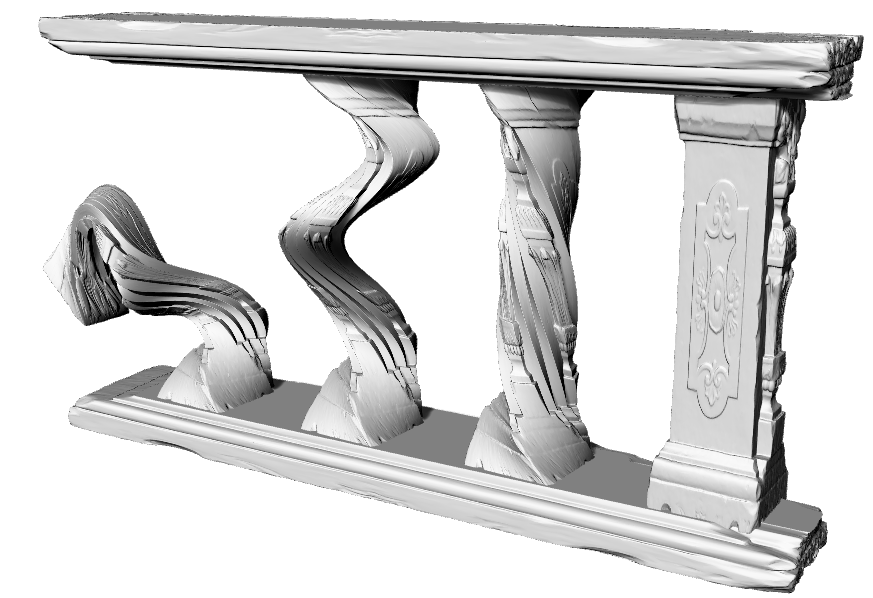

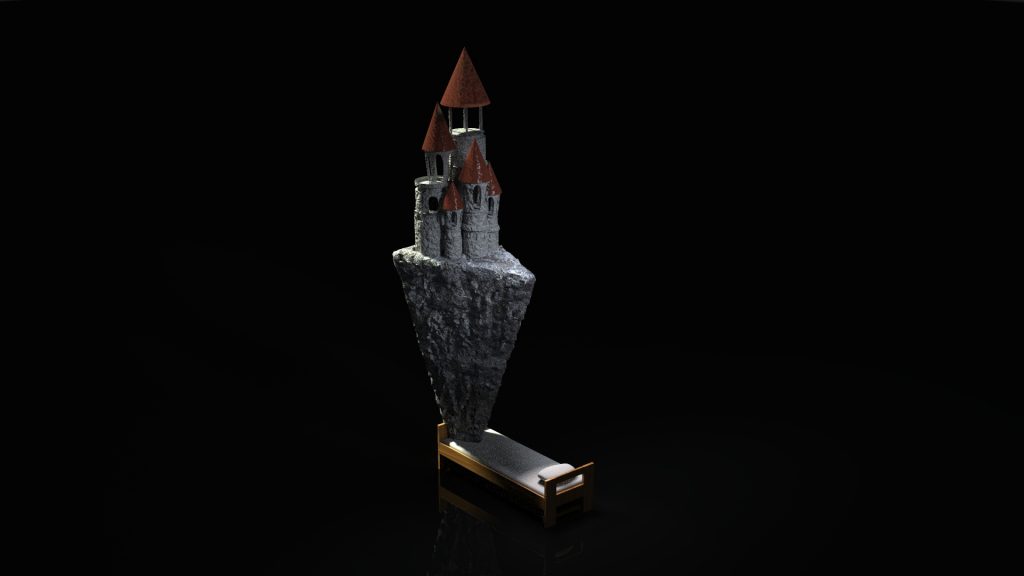

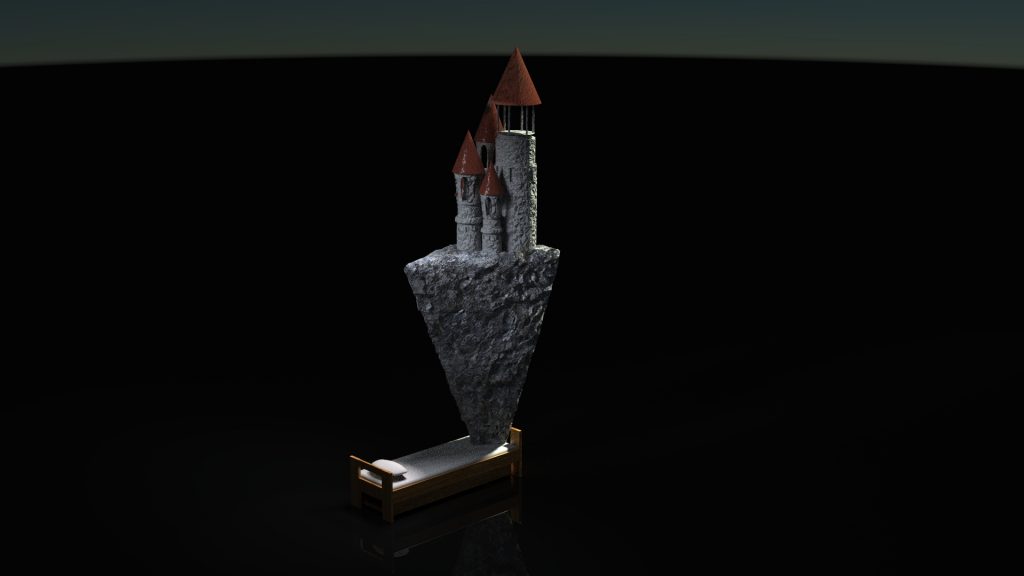

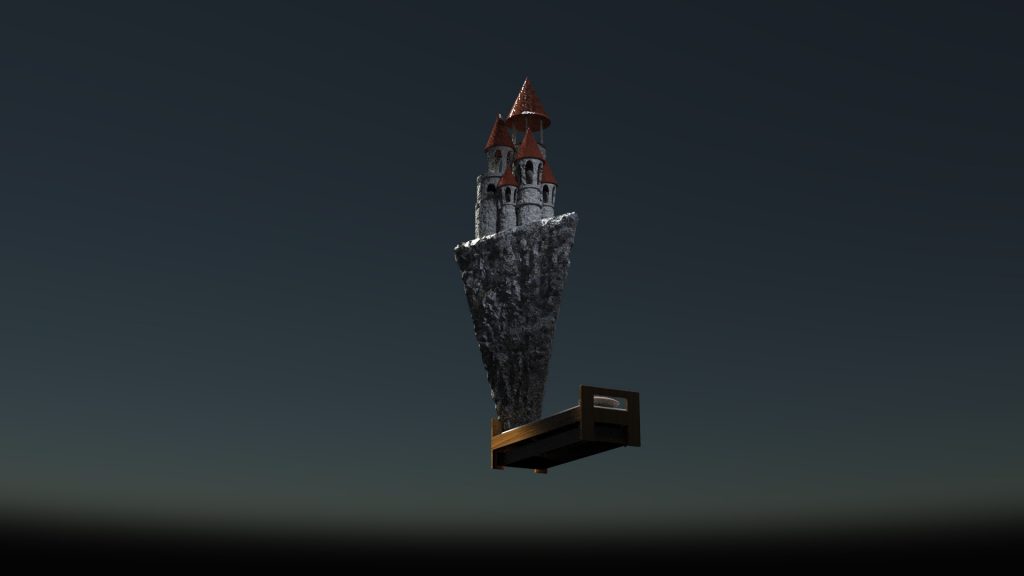

James Bennett, Project 4 Final Renderings

Project 4 update – Rachel Michael

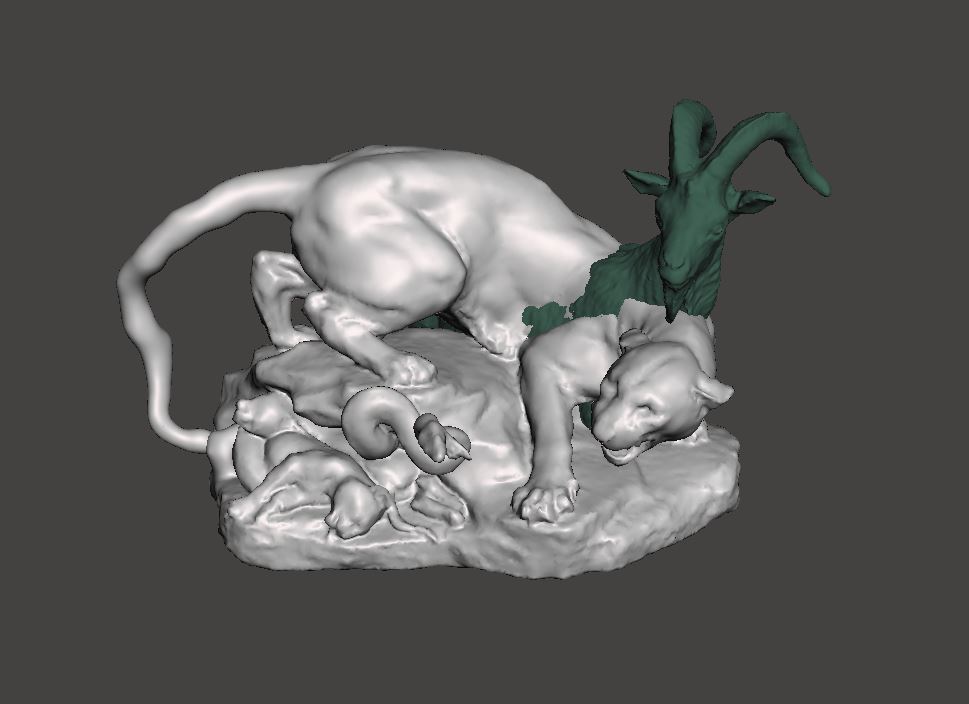

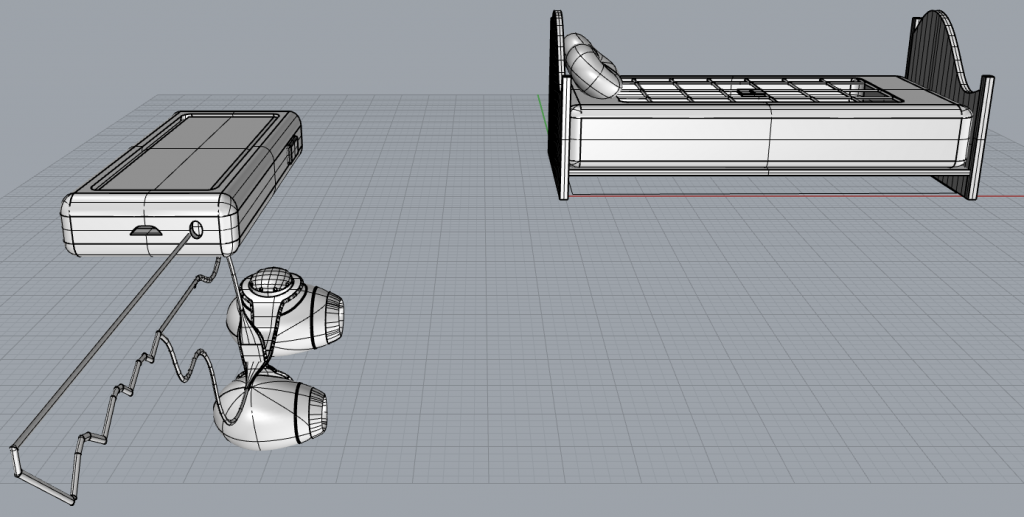

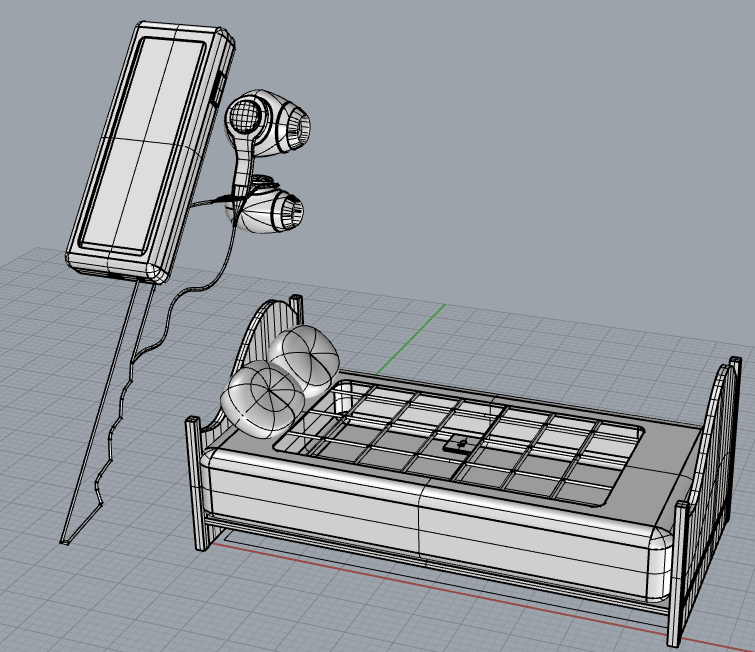

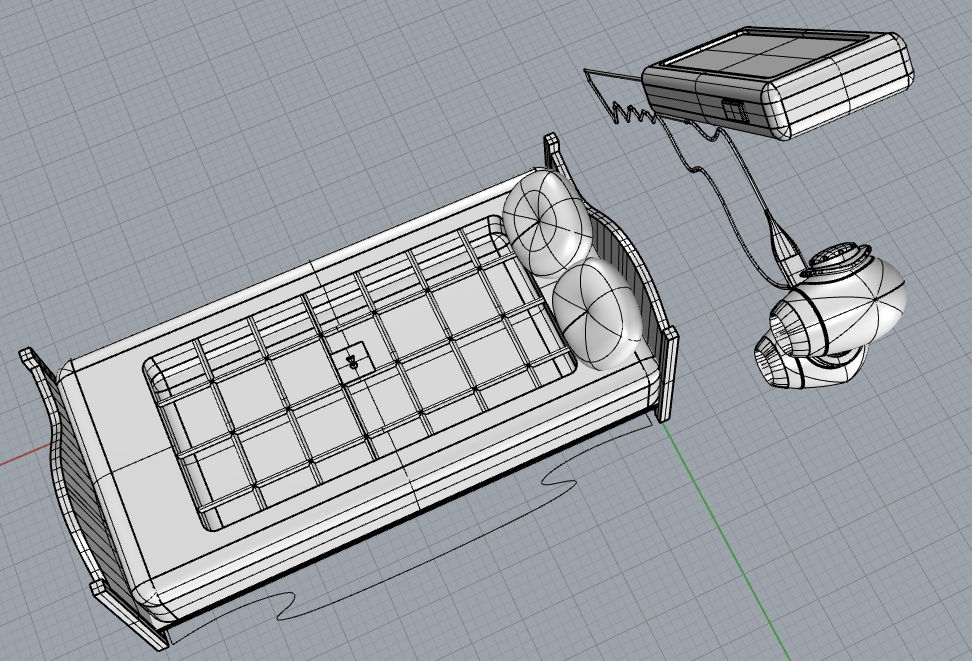

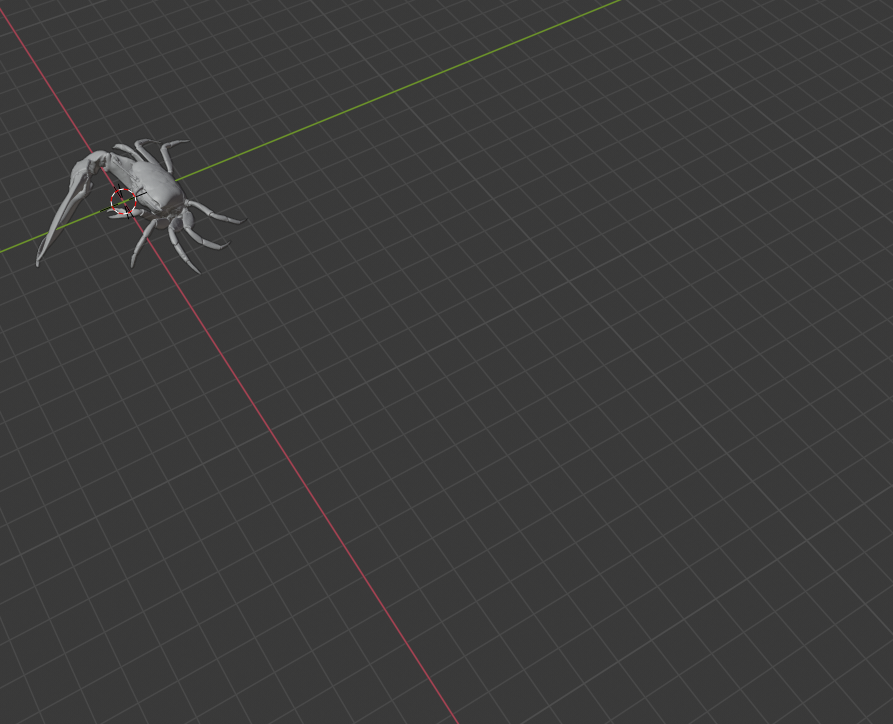

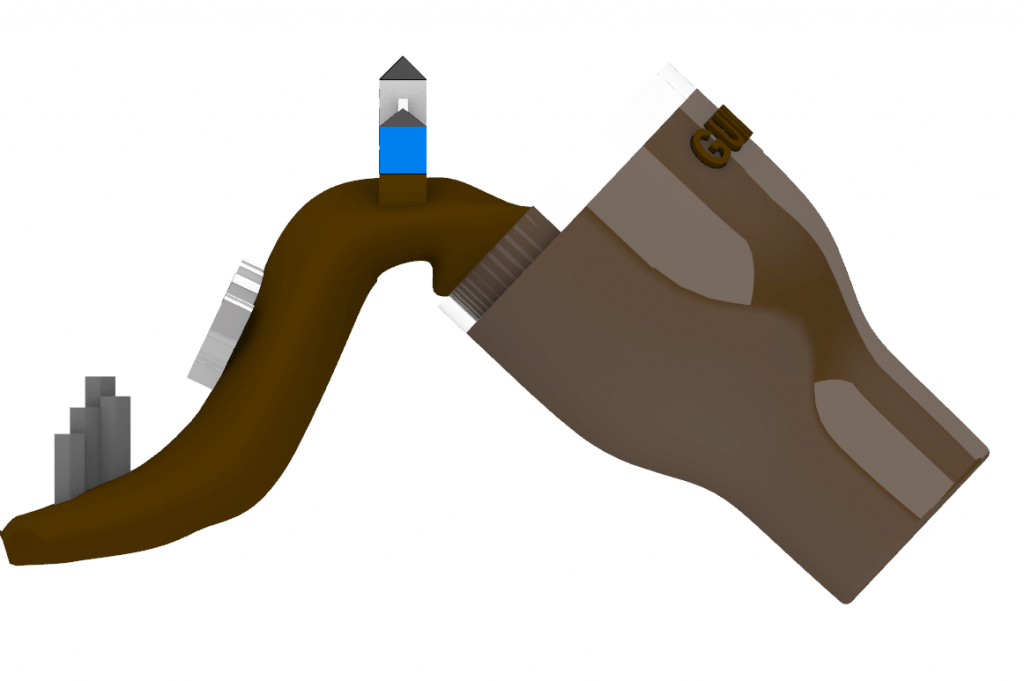

Aaron Li project 4 progress

Project 4 Update

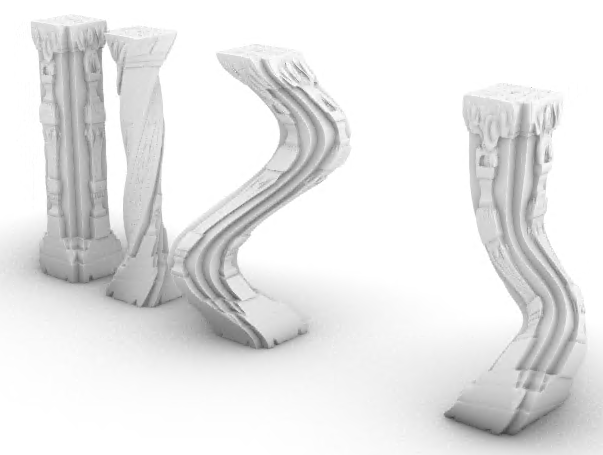

Distortion Project Update 1

Project 4 Progress

Project 4 Progress

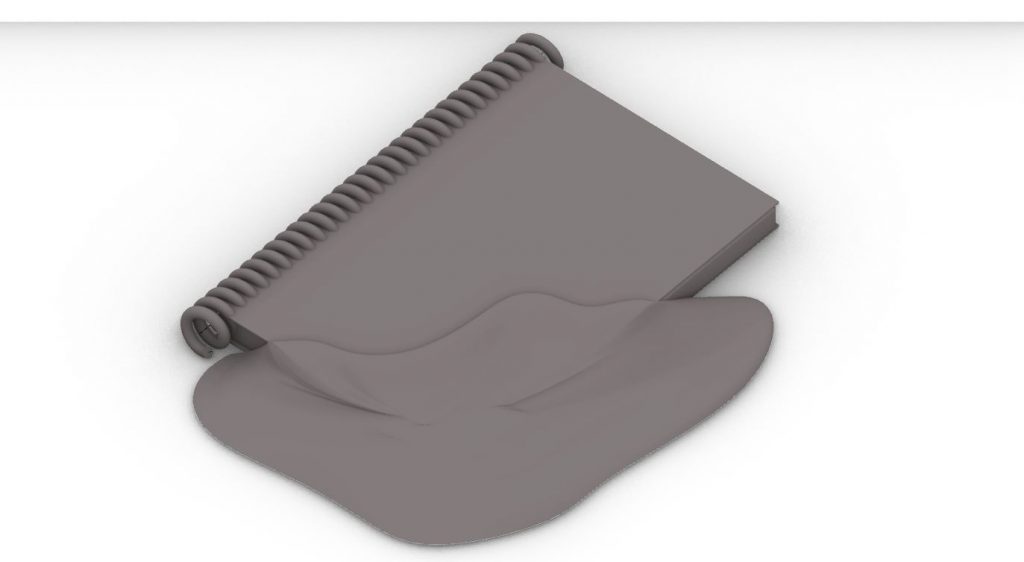

Amy Lowe-Project 4 Progress

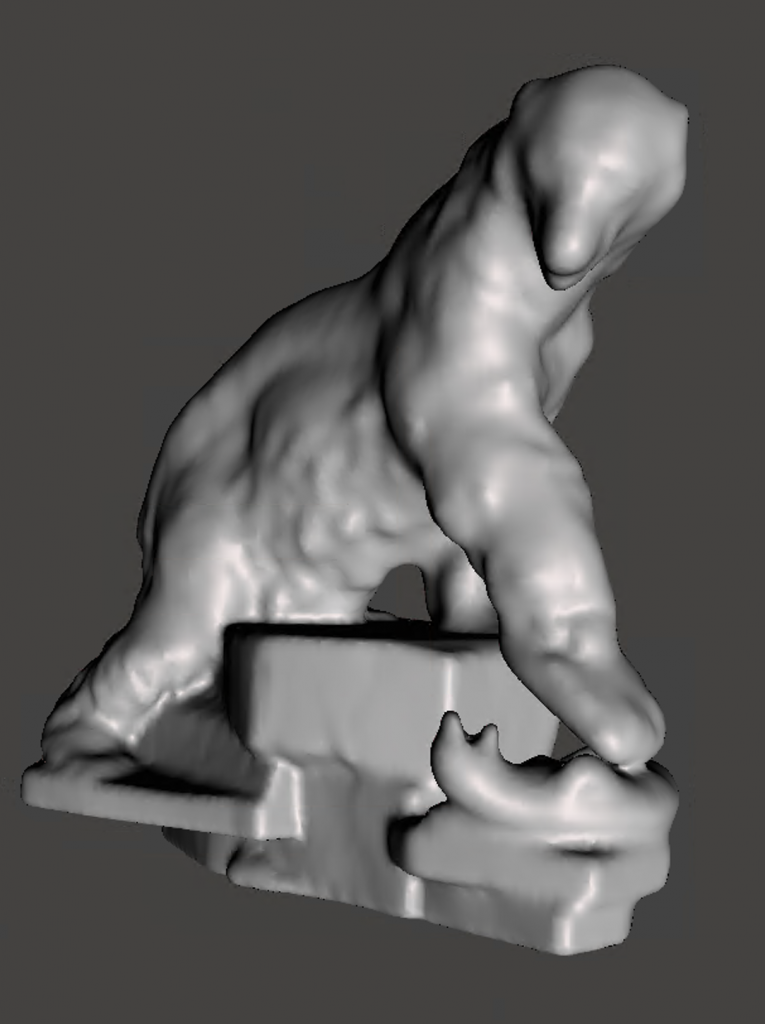

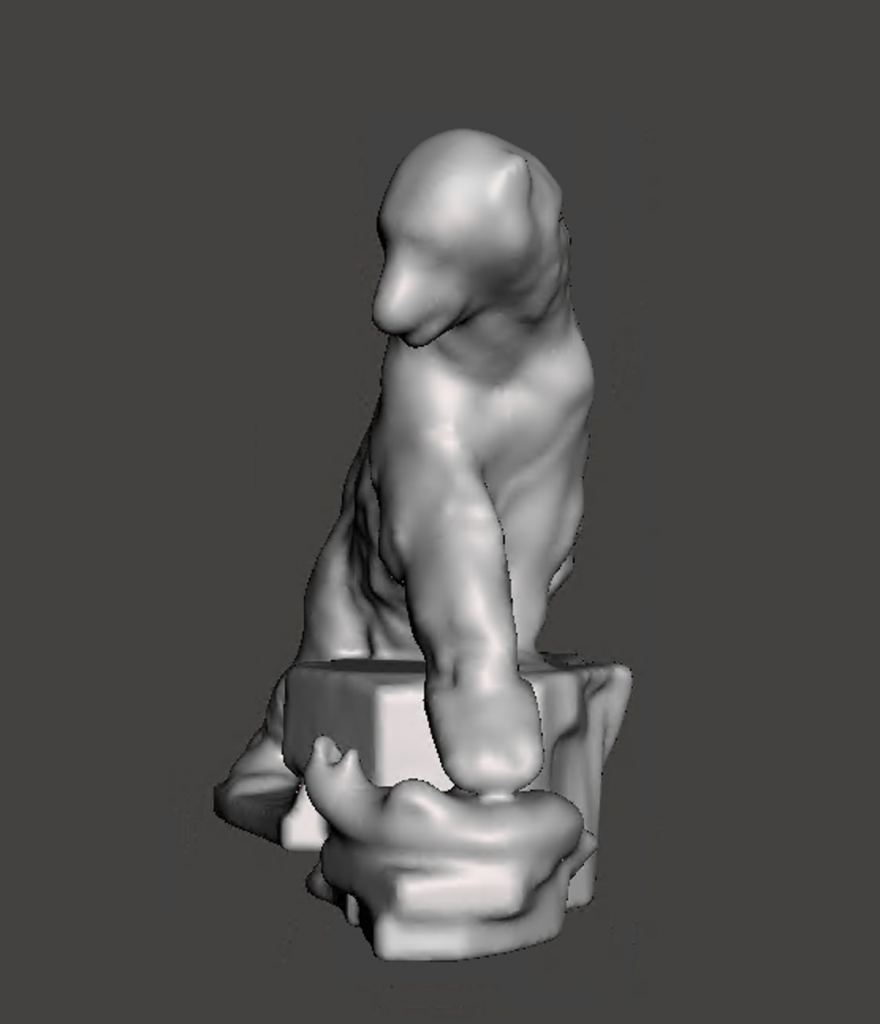

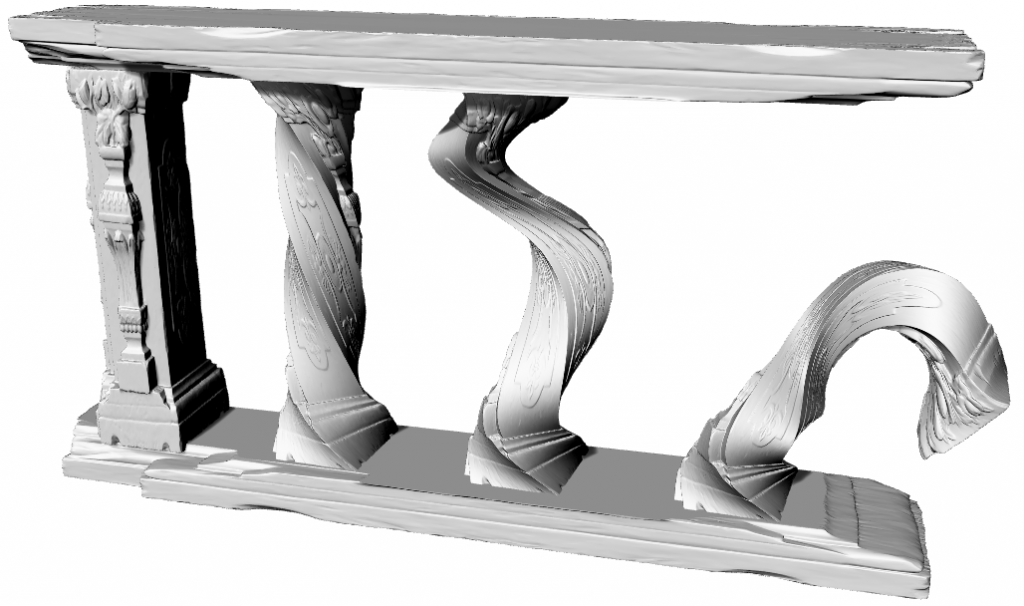

James Bennett, Project 4

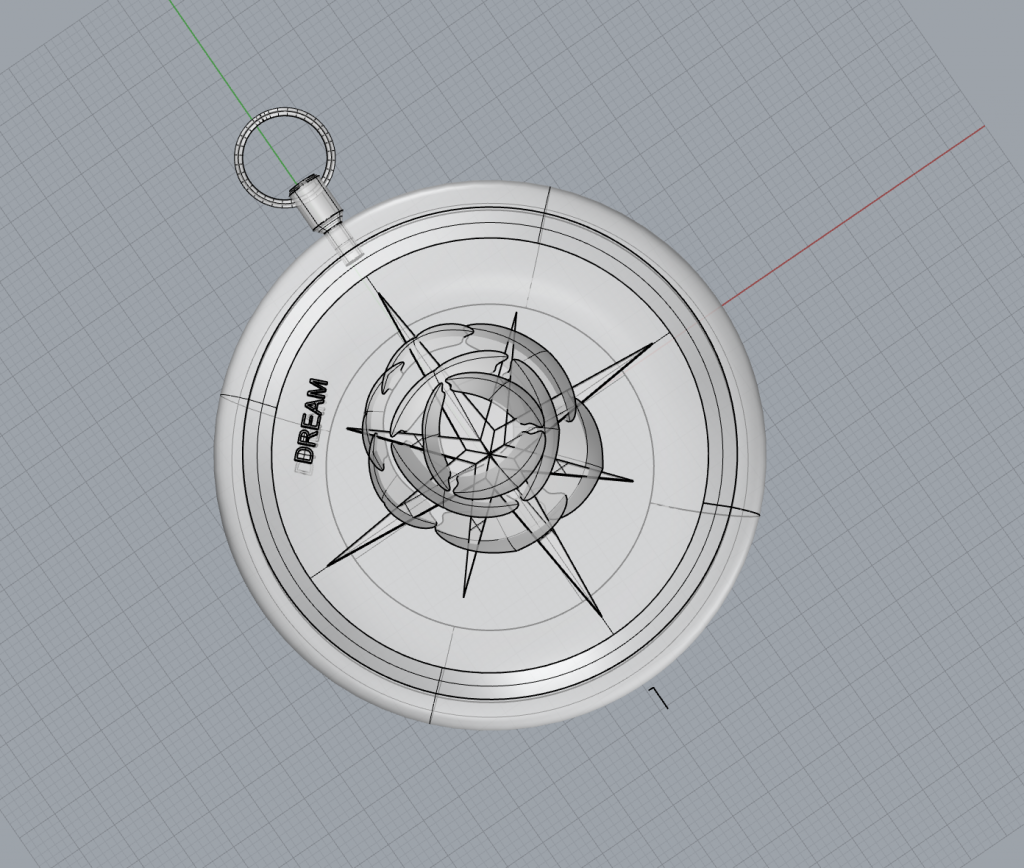

Weiwei Gu-Project 4 Progress Report 1

Marisa Morakis, Project 4 Progress

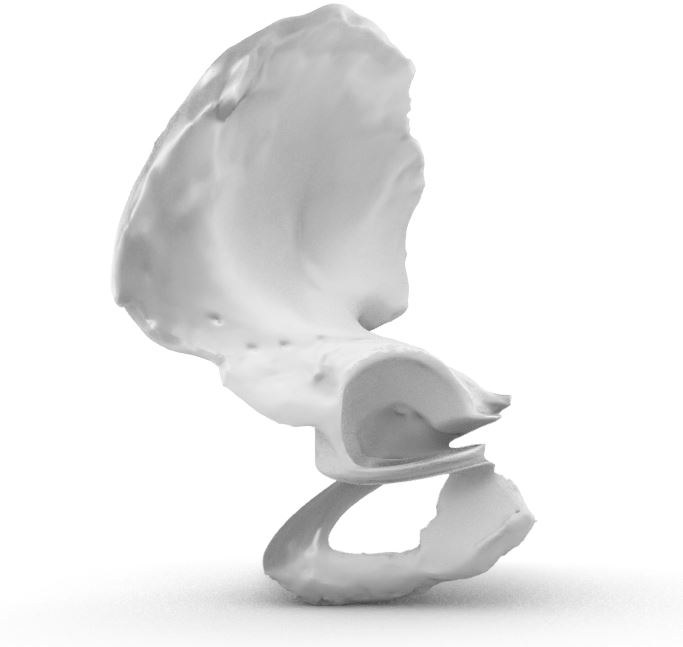

Marisa Morakis, Bust Resubmission

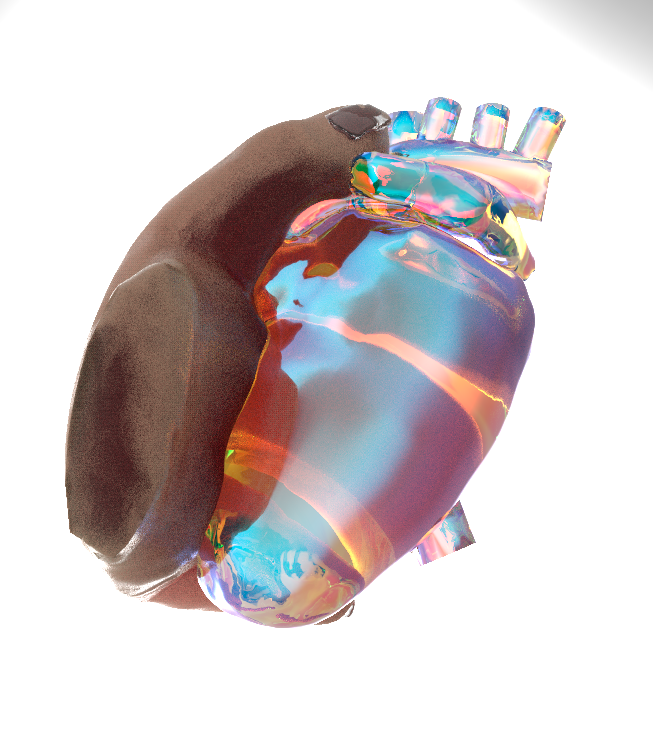

Renders

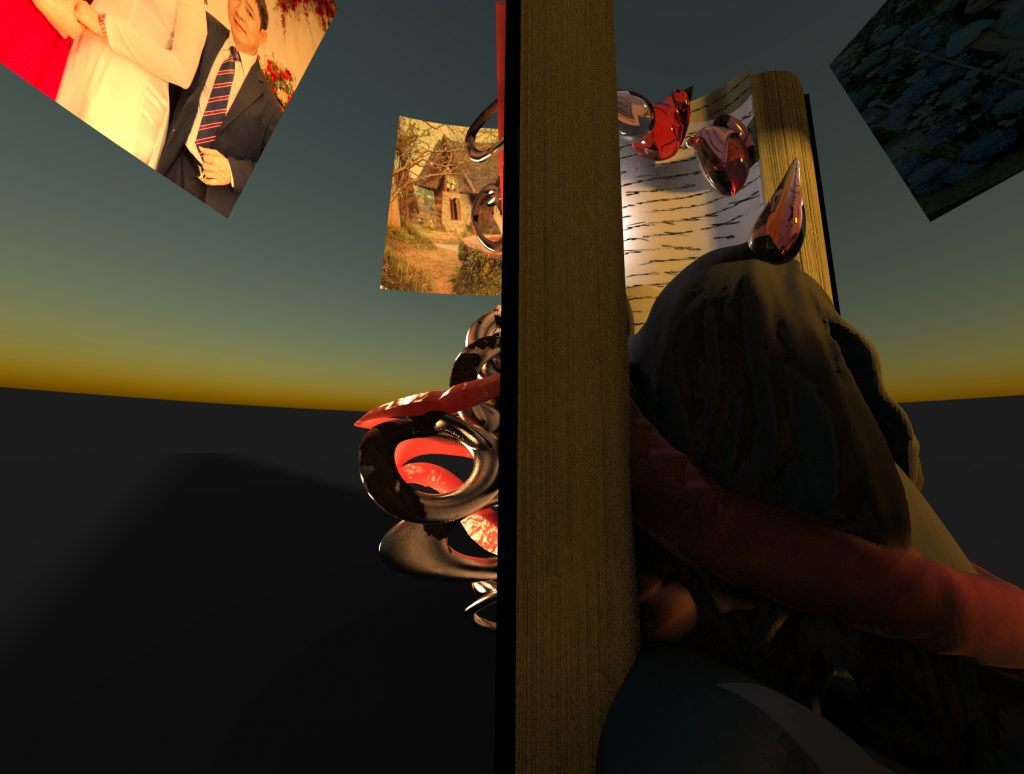

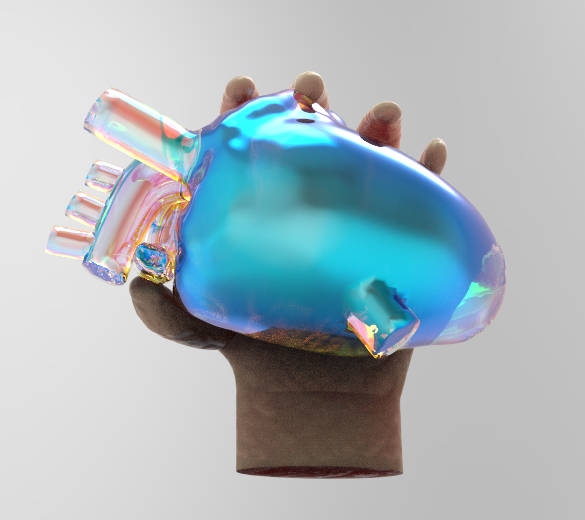

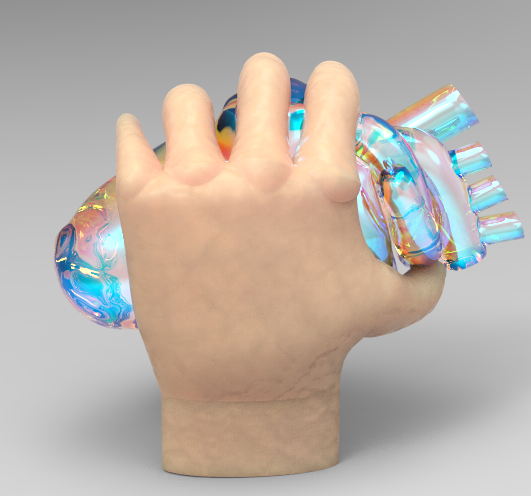

Amy Lowe-Metaphorms

Rebecca Rosenberg, Metaphorms

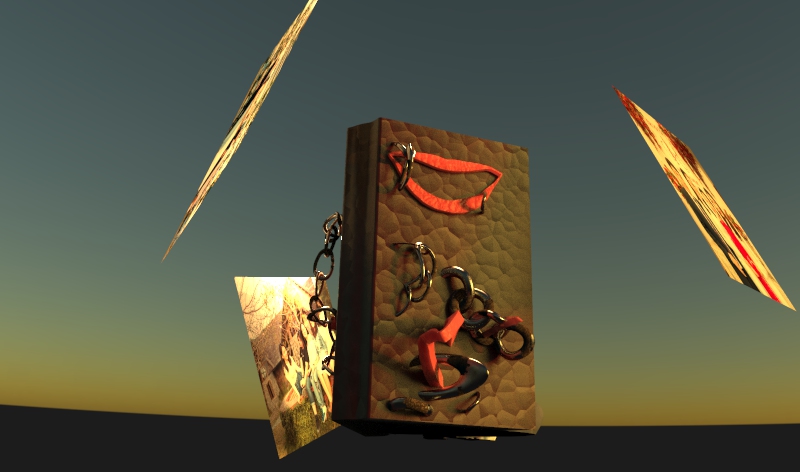

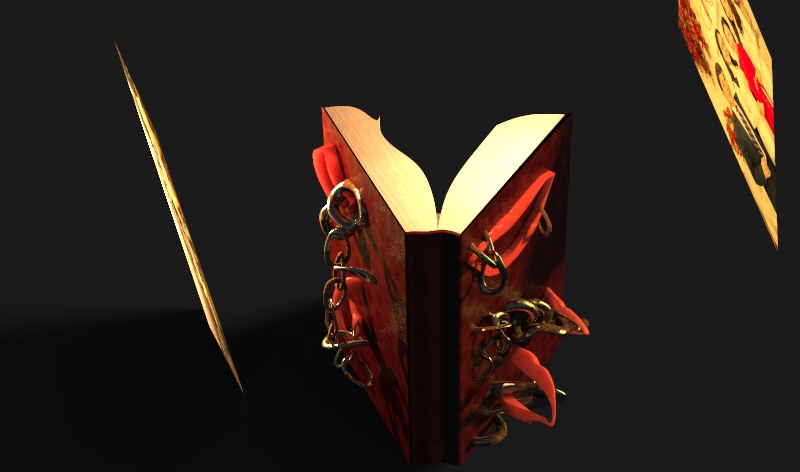

Metaphorm – Entrapment

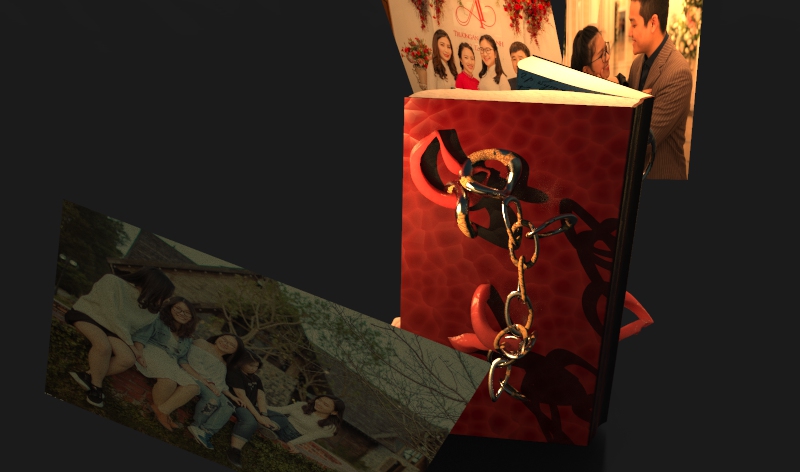

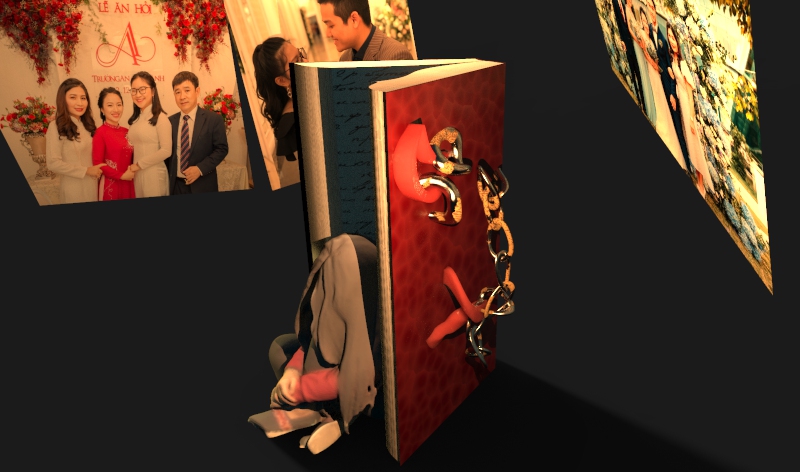

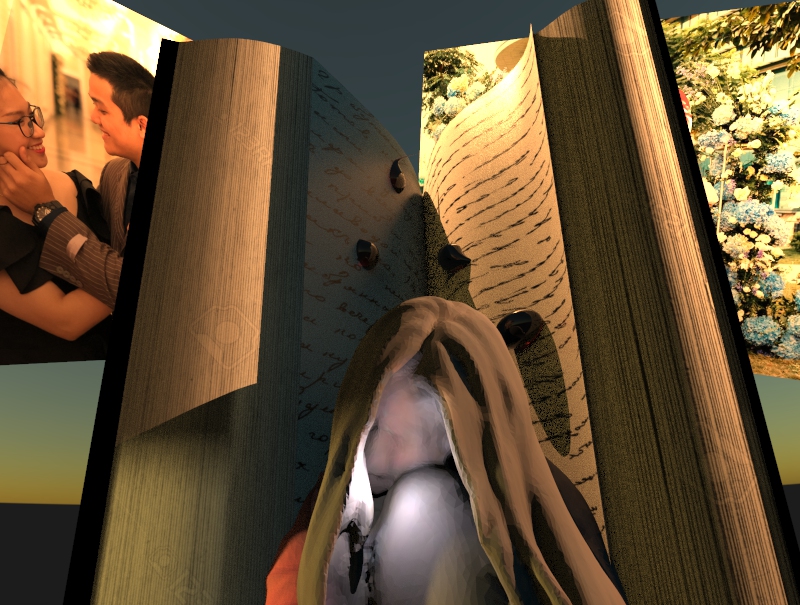

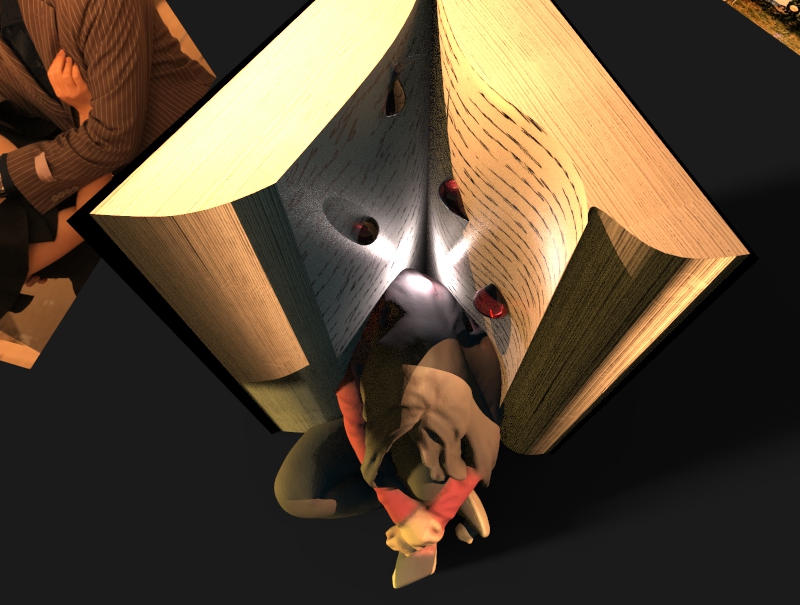

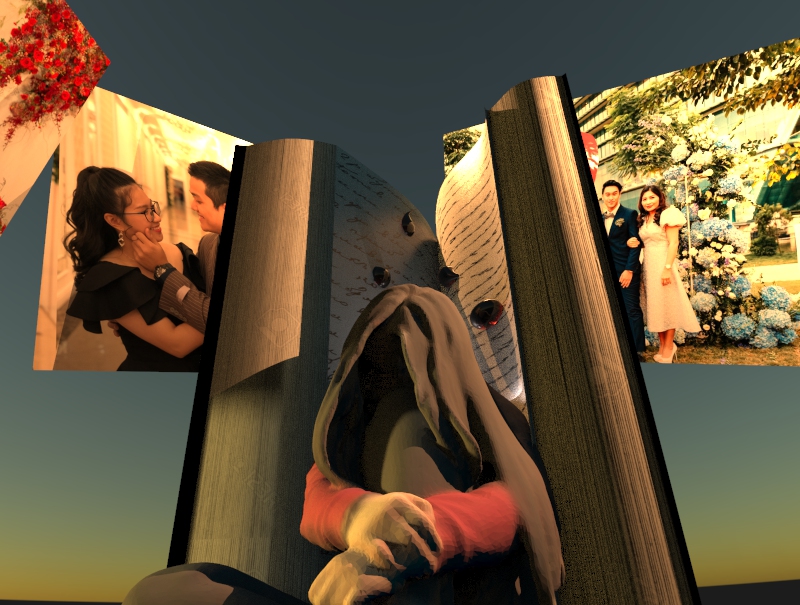

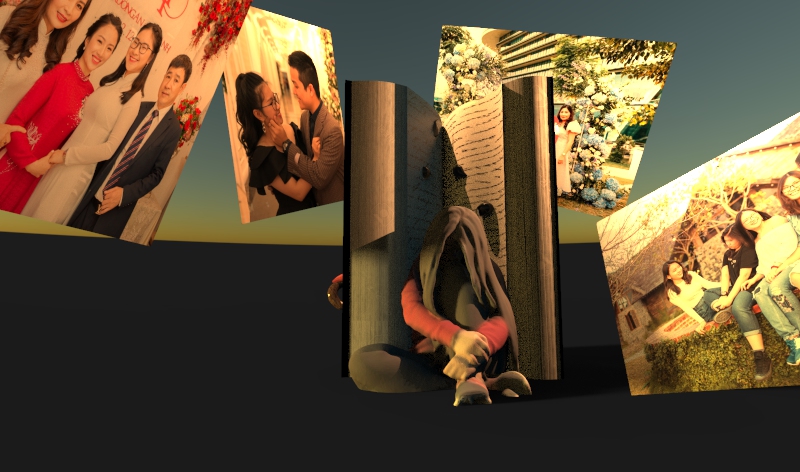

Minh Anh Phan – Project 3 Final

Charles Zhang-Project 3 Renders

Aaron Li, project 3 renders

James Bennett, Metaphorm Final

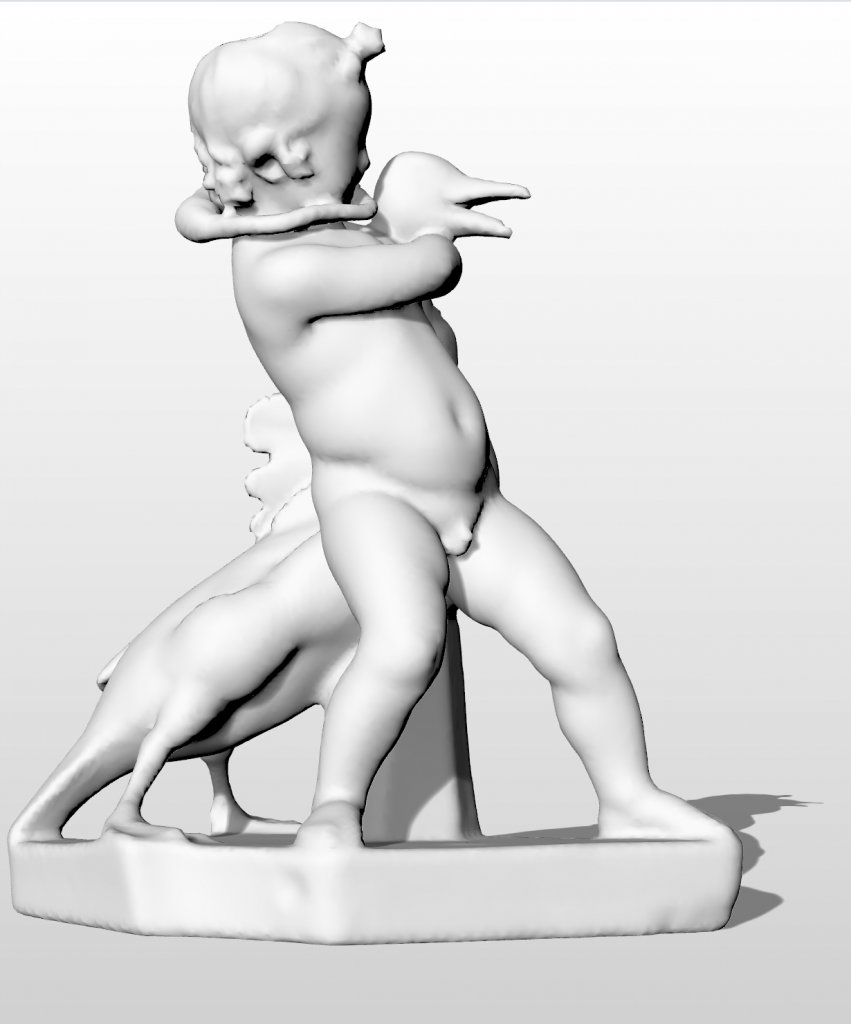

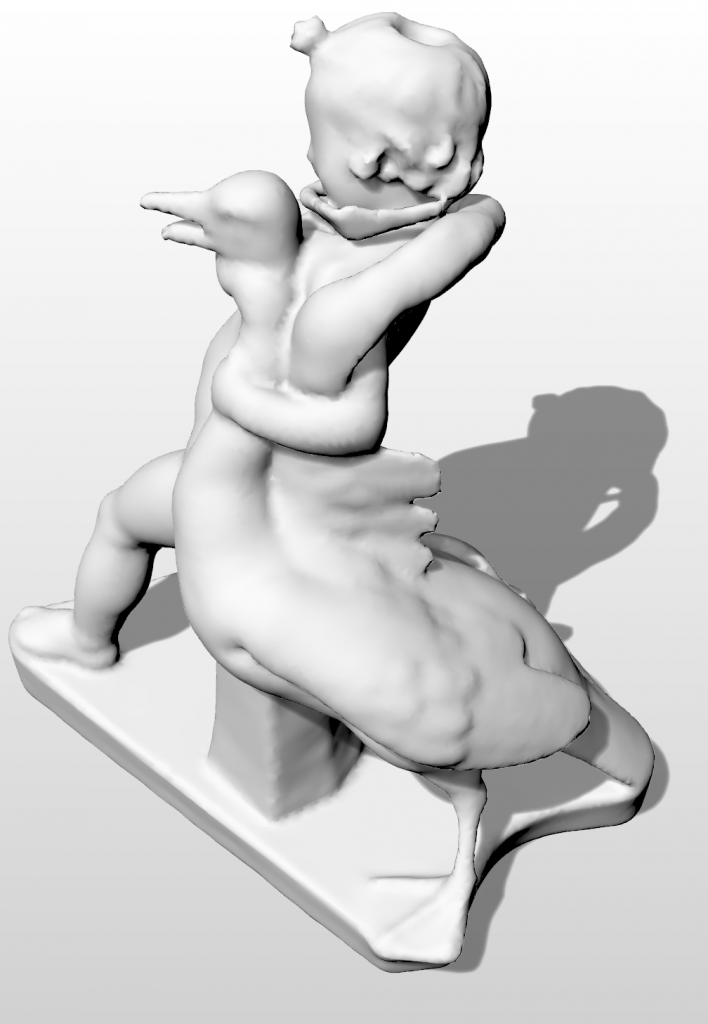

Marisa Morakis Project 3 Renders

Final Metaphorms Renders

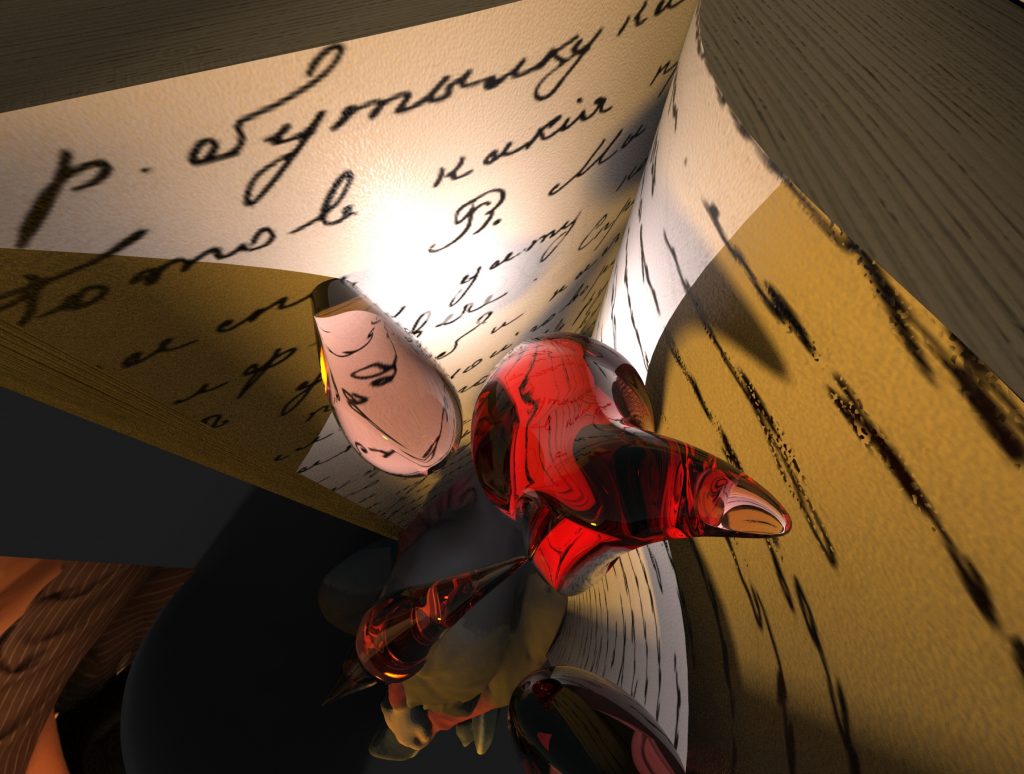

Weiwei Gu_Project3 Rendered

James Bennett, Metaphorms_Rev03

Minh Anh Phan – Project 3

Weiwei Gu-Rendered

Metaphorms Update 4 – First Render

Project 3-Progress 3

Metaform Progress 3

Minh Anh Phan – Progress Project 3

Aaron Li metaphorms progress

Metaphorms Update 3

Rebecca Rosenberg, Metaphorms Project Update

Amy Lowe-Metaphorms Progress 3

Weiwei Gu- Progress Report 3

James Bennett, Metaphorm Rev02